Did you know that assembly operations can account for a staggering 40-60% of total manufacturing costs? For complex products like electronics or automotive components, this figure can be even higher. This significant expense is a major concern for manufacturers looking to optimize their production processes.

Simplifying product designs to make assembly faster, easier, and less expensive is crucial. By adopting a systematic approach that focuses on assembly efficiency from the earliest design stages, you can dramatically reduce manufacturing costs. This methodology tackles assembly challenges during the design phase, transforming potential problems into significant cost savings.

By implementing principles that streamline the assembly process, you’ll not only reduce production costs but also achieve a faster time to market and higher product quality. As companies across industries adopt this approach as a competitive advantage, it’s clear that understanding its importance is vital for success.

What is Design for Assembly (DFA)?

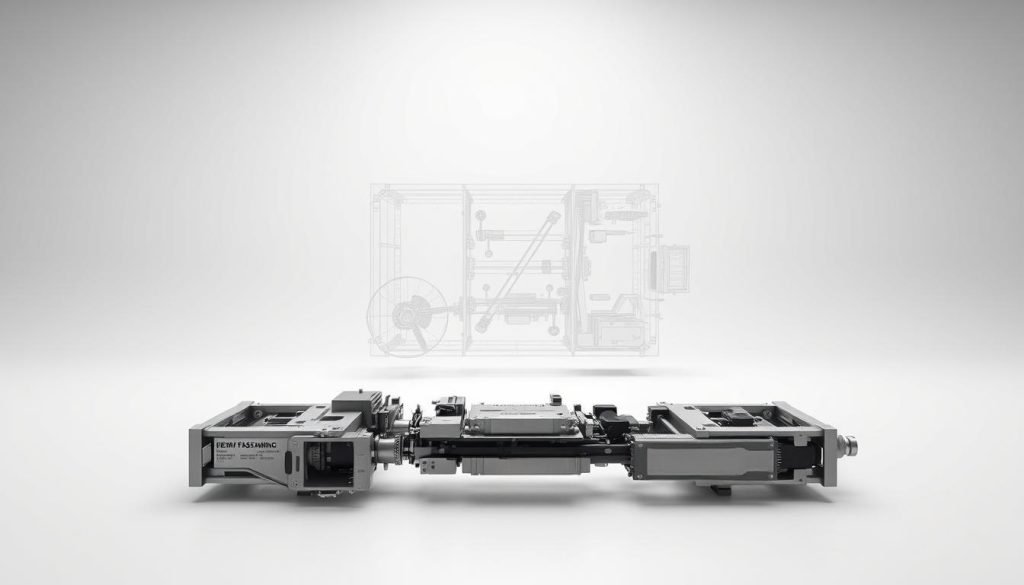

Design for Assembly, or DFA, is a crucial methodology in product design that focuses on simplifying the assembly process. By analyzing each component and connection point, engineers can create products that require fewer parts, less time, and lower costs to assemble.

Definition and Core Concepts

At its core, DFA is about questioning every component’s necessity. Designers constantly ask, “Is this part necessary?” or “Can these two parts be combined?” to drive simplification. This approach transforms how engineers approach product development, focusing on simplifying the assembly process from the earliest design stages. By doing so, DFA shifts the paradigm by addressing assembly considerations during initial design rather than troubleshooting problems during production.

The Importance of Design for Assembly in Manufacturing

In today’s competitive manufacturing landscape, Design for Assembly plays a vital role in reducing costs and improving product quality. By integrating DFA principles early in the product development cycle, manufacturers can avoid costly redesigns and production delays, ultimately leading to more efficient and cost-effective production processes.

Cost Reduction Benefits

The implementation of Design for Assembly principles delivers significant cost reduction benefits by minimizing part count, which directly decreases inventory costs, assembly time, and the resources required for production. By streamlining assembly operations, companies can reduce their production costs substantially. Fewer parts mean less complexity in the assembly process, leading to lower labor costs and reduced expenditure on inventory management.

Quality and Time-to-Market Improvements

DFA creates a competitive advantage through dramatic improvements in time-to-market, allowing companies to launch products faster by streamlining assembly operations and eliminating potential production bottlenecks before they occur. Quality improvements are a natural byproduct of DFA implementation, as fewer parts mean fewer potential failure points, while standardized assembly processes reduce variation and the likelihood of assembly errors.

The Relationship Between DFA, DFM, and DFMA

As you delve into product design, it’s essential to grasp how DFA, DFM, and DFMA work together to enhance manufacturing efficiency. DFA doesn’t exist in isolation; it works alongside Design for Manufacturing (DFM), which focuses on making individual parts easier to manufacture. Together, they form Design for Manufacturing and Assembly (DFMA).

Design for Manufacturing (DFM) Overview

DFM is a methodology that optimizes individual parts for efficient production. It considers factors like material selection, production processes, and manufacturing capabilities to create components that can be manufactured cost-effectively. By applying DFM principles, you can significantly reduce production costs and improve product quality.

How DFA and DFM Work Together as DFMA

DFA and DFM work together synergistically as DFMA to create products that are optimized for both efficient production and assembly. While DFM ensures that each part can be produced efficiently, DFA ensures that all parts can be assembled efficiently. This combined approach leads to optimal results in product design and manufacturing.

Key Differences Between DFA and DFM

The primary difference between DFA and DFM lies in their focus areas. DFM concentrates on making individual parts easier to manufacture, whereas DFA focuses on how those parts come together during assembly. Both methodologies share the common goal of reducing costs but approach it from different angles. Understanding these differences is crucial for effectively implementing DFMA in your product design process.

Core Design for Assembly Principles

To improve assembly efficiency, it’s essential to grasp the fundamental principles of DFA. These principles are designed to simplify the assembly process, reduce production costs, and enhance product quality. By applying these principles, you can significantly improve the manufacturability of your products.

Minimizing Part Count

Minimizing part count stands as the most powerful DFA principle. Every component eliminated from a design removes an assembly step, reduces inventory needs, and eliminates a potential failure point. You should constantly question whether each part serves an essential function by asking: Does this part move relative to other parts during operation? Must this part be made of a different material for functional reasons? Must this part be separate to allow assembly or disassembly?

Standardization and Modularization

Standardization and modularization create significant assembly advantages. By using common components across multiple products, you can reduce training requirements, minimize tooling changes, and simplify inventory management. This approach enables a more streamlined production process and improves overall efficiency.

Designing for Ease of Handling and Insertion

Parts that are difficult to handle or orient create assembly bottlenecks. DFA principles address this through specific design guidelines: designing parts with symmetry where possible, exaggerating asymmetry when symmetry isn’t possible, and including features that prevent incorrect assembly. By doing so, you can simplify the handling and insertion process, reducing assembly time and improving product quality.

Assembly Motion Analysis and Optimization

The final core principle examines the physical movements required during assembly. Efficient DFA minimizes complex motion sequences and reduces the force needed to join components. You can achieve this by favoring straight-line “top-down” assembly motions, eliminating the need to flip or reorient the assembly, and designing for progressive assembly in a single direction. This approach optimizes the assembly process, making it more efficient and cost-effective.

Implementing DFA Methodology in Product Development

The key to successful DFA implementation lies in following a logical sequence that starts with baseline analysis. To effectively integrate Design for Assembly (DFA) into your product development process, you must understand the structured methodology it entails.

Step-by-Step DFA Implementation Process

Implementing DFA methodology in product development follows a structured, step-by-step process. It begins with a baseline analysis of the current assembly process, including time studies, defect rates, and cost breakdowns. This step is crucial for establishing metrics to measure improvement.

A cross-functional team is then formed, comprising design engineers, manufacturing engineers, assembly operators, and quality specialists. Each member brings a unique perspective to the DFA analysis, ensuring a comprehensive evaluation.

The process continues with product teardown, where every assembly step is documented, and difficult operations are noted. DFA metrics are then applied to evaluate each component, and alternative designs are generated to address identified issues.

Tools and Software for DFA Analysis

Several established methodologies support DFA implementation, including the Boothroyd-Dewhurst Method, Lucas Method, and Hitachi Assembly Evaluation Method. The Boothroyd-Dewhurst Method assigns time values to handling and insertion operations, providing a quantitative analysis of assembly efficiency.

Many organizations utilize specialized software tools for DFA analysis, ranging from dedicated DFA software to modules within CAD systems. These tools automate calculations and provide visualization capabilities, making DFA implementation more efficient and effective.

DFA Integration with Six Sigma and Lean Manufacturing

The integration of DFA with Six Sigma enables companies to tackle design efficiency and process quality simultaneously. By combining DFA principles with Six Sigma methodologies, organizations create a powerful approach to product development and manufacturing excellence.

DFA in the DMAIC Framework

The DMAIC framework (Define, Measure, Analyze, Improve, Control) provides a structured approach for implementing DFA within existing manufacturing operations. You’ll understand how DFA fits into this framework, enhancing assembly improvements. By applying DFA principles, companies can simplify the design process, reducing the complexity of assembly operations.

Quality Improvement Through DFA

DFA contributes significantly to quality outcomes through multiple mechanisms. Fewer parts mean fewer opportunities for defects, while simplified assembly reduces operator errors. Standardized components improve consistency, and self-aligning features prevent misassembly. By incorporating DFA into Design for Six Sigma (DFSS) methodologies, teams can prevent assembly problems before they occur, rather than retrofitting existing designs.

Common Mistakes and Solutions in Design for Assembly

As you embark on a DFA journey, it’s crucial to be aware of the frequent challenges that can impact your results. Even well-planned DFA initiatives can encounter obstacles that affect their effectiveness.

Overlooking Assembly Sequence

One of the most common mistakes in implementing DFA is overlooking the assembly sequence. The order of assembly operations significantly impacts efficiency, requiring engineers to analyze the entire sequence rather than focusing solely on individual components. By optimizing the assembly sequence, you can reduce assembly time and improve overall productivity.

Ignoring Manufacturing Constraints

Ignoring manufacturing constraints can undermine DFA efforts, as some assembly-friendly design changes may create manufacturing difficulties. It’s essential to consider DFM alongside DFA throughout the design process. This integrated approach ensures that design improvements do not compromise manufacturing efficiency.

Conclusion: Future Trends and the Evolving Role of DFA

DFA is on the cusp of a revolution, driven by advancements in AI, generative design, and cloud collaboration. As manufacturing becomes increasingly automated, the role of DFA in product development is evolving. You’ll discover how AI-assisted design systems are transforming DFA by automatically suggesting improvements based on pattern recognition from thousands of previous designs.

As DFA continues to evolve, its fundamental principles remain relevant, focusing on part count reduction, standardization, ease of handling, and optimized assembly motion. By adopting these principles and leveraging emerging technologies, you can significantly improve assembly efficiency and reduce assembly time, ultimately driving product development forward.