Machine Tools and Fabrication Changes of the Last Few Decades CNC Machines have Revolutionized Manufacturing. They have computer programs to guide tools with remarkable precision. The devices help form industries including aerospace, automotive and medical device manufacturing. They manipulate metals, plastics and composites to create parts with a precision that manual tools cannot achieve. CNC machines reduce mistakes and optimize workflow by automating processes.

They can be used for intricate designs, whether small components or large structures. This guide will delve into the main types of CNC machine tools. It describes their unique functions and how to select the best one.

Whether you are a manufacturer or just curious, you will gain an understanding of how these tools are shaping modern production. Learn what they can do and why they’re so vital to modern industries.

Classification of CNC Machine Tools

CNC Machine Tools are categorized into some common groups. They each specialize in various tasks, like shaping, drilling, or cutting. Milling machines cut complex shapes, and lathes make round parts. Drilling machines are hole-focused, and grinders are surface-focused. Electrical Discharge Machines (EDM) tackle difficult materials, and plasma or laser cutters cut with extreme precision. Their degrees of freedom are determined by the number of axes, 3 up to 5 or higher. The more axes, the more complicated the work. Also, the size of the machine and the degree of automation differ.

Some are small and intended for shops, while others are large and meant to be used in factories. This categorization makes it easier to match tools to your projects. It’s designed to be efficient and high-resolution. Here are some important factors of classification:

- Specialized Design: Each machine is designed for one purpose only: for milling, or for cutting, and so on.

- Axis Flexibility: Machines with a greater number of axes work with complex shapes more effectively.

- Automation Choices: More sophisticated production systems utilize robotics to move production along.

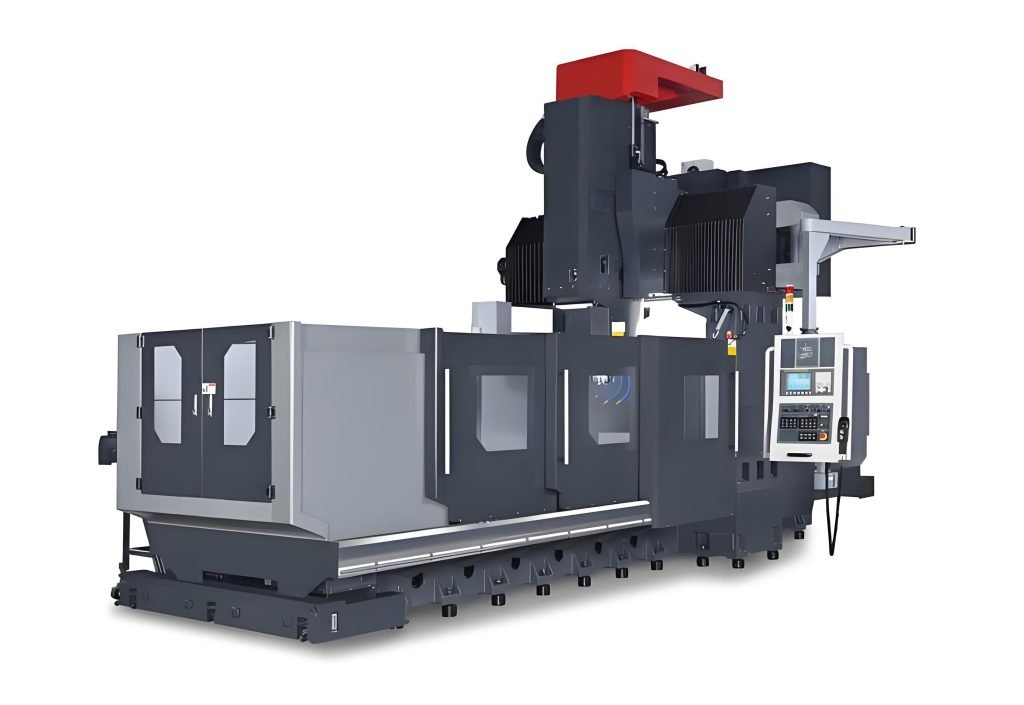

CNC Milling Machines

CNC milling machines are incredibly powerful machines, and we are fortunate to have access to a lot of them. They are used to form external threads on a workpiece. Operating on 3 to 5 axes, they execute wherever movement is needed for accuracy. These machines make parts such as gears, brackets, and engine blocks.

The aerospace and automotive industries depend on them for precision. They work with materials that include steel, aluminium and composites. Automatic tool changers change cutters in the blink of an eye, so to speak. If fine-tuning is not required, then verticals work, but for bigger jobs, horizontals work best. Higher-end models have built-in cooling fans to help prevent overheating.

This permits that quality to be sustained over long runs. CNC milling machine for rapid prototype and mass production. They produce premium quality parts with little waste and are machine shops of choice for companies that demand high standards and tight tolerances.

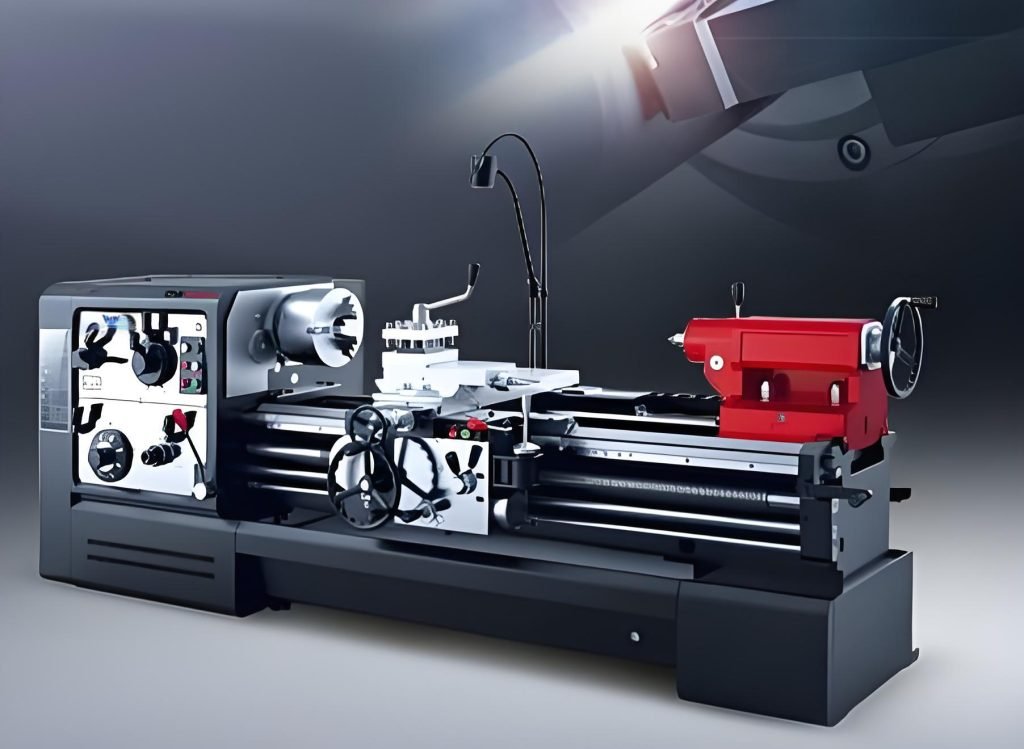

CNC Lathes

CNC Lathes spin workpieces against a fixed cutting tool to produce cylindrical parts. They manufacture components such as shafts, pulleys and bushings. In contrast to milling, the tool moves in the rotation. This makes them perfect for rounding or coming out components. They are relied upon by industries from automotive to machinery.

They cut with 2 to 4 axes for accuracy. Advanced lathes do this while adding those extra jobs, such as drilling or milling, with what’s called live tooling. They efficiently work all metals, plastics, and wood. There are automation options for bar feeders and robotic arms to help automate processes.

They help in providing flawless finishing and uniform results. They’re great for high-volume production or custom work. CNC lathes make complex turning processes go faster and easier with precision production for manufacturers.

CNC Drilling Machines

CNC drilling machines are used to produce accurate holes using a rotating drill. To be precise, computer programs tell them how to move. In aerospace, electronics, and construction, they are crucial. They drill holes into circuit boards or steel frameworks, for instance. These machines deal with plastics, metals and composites.

Complex hole pattern and depth through multi-axis control. Automatic tool changers and multi-spindle heads accelerate high-volume operations. They also get rid of human error because the holes would be perfectly aligned. They frequently combine with milling and turning machines to create whole parts. CNC drilling machines can save time and labour costs. They are crucial for projects that require consistent and repeatable hole-making. Key benefits include:

- Precision: Computerized drilling means perfect holes and locations.

- Material Flexibility: They can drill just about anything between soft plastics and hard metals.

- Quick Turnaround: Automation options such as multi-spindle heads help increase productivity.

CNC Grinding Machines

CNC Grinding machines are used for – Automatic Grinding with Diamond or CBN wheels. This process ensures smooth surfaces and close tolerances. These machines are vital for the aviation and automotive sectors. They buff parts like turbine blades and engine components. Surface grinders are used to flatten surfaces, while cylindrical grinders shape curves.

Centerless grinders are ideal for small, high-volume production of precision parts such as pins and rollers. They work with steel, ceramics, and composites. Automated wheel dressing ensures that tools are sharp and cutting is accurate. Quality while grinding is monitored using in-process measuring. This ensures that the internal information is correct and stays that way.

CNC grinders are perfect for most, if not all, parts that need to be long-lasting and have a neat finish. They reduce manual labour and are ideal for mass production. Because of their accuracy and dependability, they are an essential part of good production practice.

CNC EDM (Electrical Discharge Machines)

CNC Electrical Discharge Machines (EDM) are one of the equipment types that is used to mold hard materials with the help of electrical sparks. They never contact the workpiece, so there’s no tool wear. That makes them ideal for hard metals like titanium or hardened steel. Wire EDM relies on a thin wire to cut exact shapes.

Cavities with shaped electrodes are formed by sinker EDM. Among other things, they are used for mold, dies and aerospace parts. Spark intensity is controlled through CNC for accuracy. These are the machines that get the job done when conventional tools don’t cut it. An automated electrode changer can dramatically reduce the time between parts for small-batch or prototype work.

They master complex designs and small tolerances. Industries with complex, durable parts rely on CNC EDM. Its one-of-a-kind spark technology provides precision in hard materials, and it’s a game changer for the specialized manufacturing process.

CNC Plasma and Laser Cutting Machines

CNC plasma and laser cutters make precise, high-speed cuts through solid materials. Plasma cutters cut conductive metals, such as steel and aluminium, using a high-velocity jet of ionized gas. They’re perfect for heavy-duty work in construction or shipbuilding.

Laser cutters rely on focused beams for precise, detailed cuts. They deal in metals, plastics, wood and, at times, even fabrics. Their precision finds appreciation in the electronics and auto sectors for fine designs. Both machines go by CNC paths, providing repeatability. Laser cutters excel at fine work; the plasma cutters handle thicker stuff. Automated systems, such as height control, guarantee you do not get recutting and deliver clean cuts.

The machines cut down on waste and accelerate production. They’re essential for manufacturers who require fast, precise cutting solutions for a variety of projects.

Fecision CNC Solutions: Precision and Reliability for Modern Manufacturing

Fecision brings the new CNC era to you. Leaders in the industry, we provide the best quality milling, lathe and cutting machines available. Fengchi’s tools are designed for contemporary manufacturing to improve productivity. They enable industries to effortlessly spawn high-quality parts. Rely onFengchi to energize your productivity with technological superiority.

Factors Influencing Tool Selection in CNC Machining

Selecting the appropriate CNC machine is essential to serving your needs. Start with material type. Hard metals such as titanium require EDM, and plastics can be milled or laser cut. Part complexity matters, too. For complex designs, multi-axis machines are a must due to their flexibility. Understandably, production levels are also a major issue.

Automatic lathes or grinders can handle larger jobs. EDM is occasionally required for accuracy in low-volume prototypes. Machine features, such as a number of axes or power, must respond to the requirements of the project. Budget plays a big role. Factor in cost, maintenance, and tooling costs. Seamless integration with products and systems already in place.

The size of the workspace and safety rules may also limit machine choices. The level of skill of the operator also affects decisions. Skilled workers are needed to run sophisticated machines.

By considering these factors, you find tools that are fastest, least expensive, and best-suited for your own shop’s manufacturing needs.

A Final Word

Modern machining isn’t possible without CNC machine tools. They provide precision, speed and flexibility. From milling and lathes to EDM and laser cutting, each has its specific purposes. They form everything from small electronics to large parts for aerospace. Making the right choice is a matter of balancing material, complexity and production requirements. CNC machines continue to get smarter as technology improves.

Automation and additional functionality add to productivity. Fecision’s creative products are the epitome of this advancement and achieve remarkable results for companies. These machines save money, cut down on errors, and free up a part of an individual’s creative energies. They enable manufacturers to remain competitive in a rapidly changing world.

CNC tools can handle complex shapes and holes in a workpiece and have the ability to remove material from their workpiece, providing them with an advantage in precision mold, dies, and certain types of parts. Harness their power to change your production and create a future of precision, productivity, and success.