Surprising fact: flexible thermoplastic materials now make up a growing share of production parts worldwide, with some industries cutting replacement cycles by over 40% using the right compound and process.

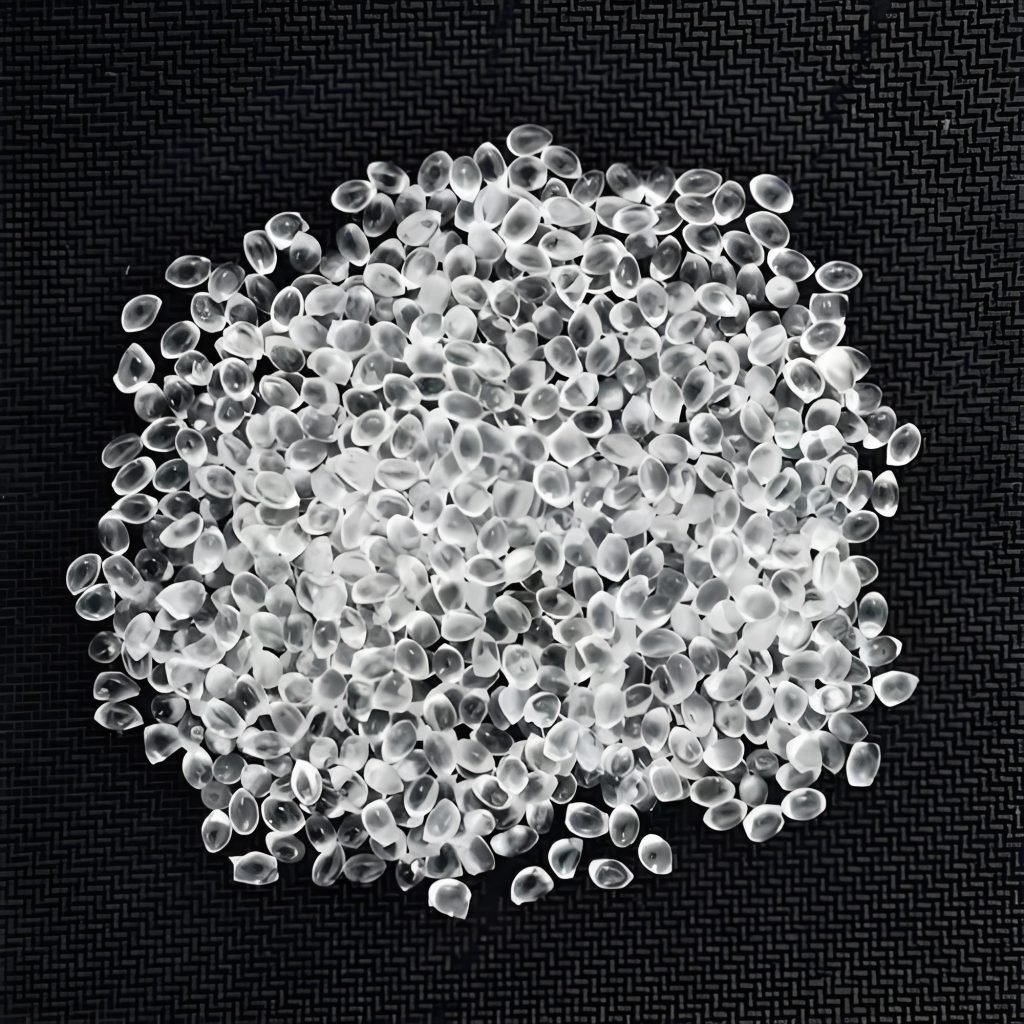

You work on designs that need stretch, strength, and long life. Thermoplastic polyurethane blends rubber-like elasticity with strong, durable behavior. This material runs on common processes: desktop printing, SLS/MJF powder systems, injection molding, and CNC machining.

Why it matters today: tpu gives you high elongation, abrasion and tear resistance, plus chemical and UV resilience. Grades span soft to hard, so you can tune parts for wear, load, or flexibility.

In this Ultimate Guide you’ll find clear advice for selecting compounds, production methods, and matching tolerances to application needs. Expect practical tips on feeder type, temperature ranges, design rules, and sourcing so your first run hits quality and schedule targets.

What Is Thermoplastic Polyurethane and Why It Matters Today

Designers choose thermoplastic polyurethane when parts must bend, absorb shock, and hold up to repeated use.

At its core, this thermoplastic elastomer is a block copolymer made from alternating hard segments (isocyanates) and soft segments (polyols). The hard blocks give strength and dimension control. The soft blocks provide flexibility, damping, and elasticity.

By changing the hard/soft ratio, manufacturers tune Shore hardness across a wide range—from very soft to semi‑rigid grades. That lets you pick a grade with the right balance of tear resistance and bendability for your product.

The chemistry also explains real-world properties: rubber-like rebound, good tensile strength, and resistance to repeated flexing. These traits make it valuable in parts that need shock absorption, vibration isolation, or long-lasting seals.

Process versatility is another benefit. You can find options for FDM/FFF filament and SLS/MJF powder, so printing tpu works from desktop prototypes to industrial production without changing the base material family.

Typical Properties of TPU Materials You Can Leverage

When you design for function and longevity, knowing key properties helps you pick the right grade. Below are the performance traits that most affect part life and day-to-day behavior.

Elasticity, elongation, and tensile strength

High elasticity and elongation let parts bend and spring back without permanent set. That makes these materials ideal for seals, bellows, and living hinges.

Tensile strength and tear values translate to longer fatigue life and safer margins under load. Use lab data to estimate cycles to failure for your application.

Low-temperature performance and weather resistance

Many grades keep elasticity at low temperatures and resist cold cracking. Outdoor grades add UV and weather resistance so parts do not degrade quickly in sun and rain.

Abrasion, tear resistance, and surface wear

Abrasion resistance extends service life on belts, rollers, and sliding surfaces. Blends or reinforcements can boost wear life where contact is frequent.

Chemical resistance and specialty grades

Polyester-based variants handle oils and fuels well, while polyether types resist hydrolysis in humid conditions.

Biocompatible and transparent grades exist for medical devices and inspection windows. Note: control moisture and drying to protect mechanical targets during processing.

Types of TPU Plastic and Their Chemistry

Not all flexible materials share the same backbone. Chemistry defines strength, resistance, and where a material performs best.

Polyester-based vs. polyether-based

Polyester grades give higher tensile and tear strength. They also resist oils and grease, so pick them for parts exposed to fuels or lubricants.

Polyether grades stay flexible at low temperatures and resist hydrolysis and microbial attack. Use them in humid or cold applications.

Aliphatic grades for color stability

When color and outdoor appearance matter, aliphatic chemistry prevents yellowing. Choose it for exterior trims and clear cosmetic parts.

Hardness range and bio-based options

Shore spans from soft ~60A up to rigid ~80D, letting you tune feel and load capacity. Match Shore to the product’s flex and wear needs.

Bio-based formulations from BASF Elastollan N, Lubrizol Pearlthane ECO, and GRECO Isothane help sustainability goals while keeping core properties intact.

Different Processing Methods for TPU

Choosing the right production route determines whether your part meets performance, cost, and time targets.

Start by matching volume and accuracy to technology. For quick prototypes, deposition modeling with desktop printers is fast and low-cost. For short runs or end-use flexible parts, consider more scalable additive manufacturing options.

FDM/FFF with TPU filament: accessibility and tuning

FDM is the most accessible printing route. Use direct-drive extruders, slow feed rates (~20 mm/s), and nozzle temps of 224–250 °C. Set minimal retraction and layer heights of 0.1–0.2 mm.

Mount the spool above the extruder to reduce pull force. These filament tips cut stringing and jams and raise first-time success for printing tpu.

SLS with TPU powder: accuracy and no supports

SLS gives higher dimensional accuracy and supports complex geometry without support structures. Follow rules: minimum walls ~0.7 mm, clearances ~1.0 mm, and powder-escape holes ≥3–4 mm.

Plan powder removal and inspection into lead times when you choose this path.

HP Multi Jet Fusion for isotropic, production-grade parts

MJF with grades like Ultrasint TPU 90A-01 delivers near-isotropic strength, smooth surfaces, and repeatable quality. It scales well for short production runs where consistent mechanical properties matter.

Beyond additive: injection molding and CNC

For high volumes or specific surface finishes, injection molding remains efficient. CNC machining works for tight-tolerance prototypes or fixtures. Each manufacturing route changes lead times, cost per part, and inspection workflows.

Use this overview to weigh trade-offs: choose FDM for quick iteration, SLS for detail, MJF for production-ready parts, and traditional methods when volume or finish drives the decision.

Design Guide for TPU Parts

Small geometry choices decide whether a flexible component lasts or fails early.

Use clear rules for walls, wires, and clearances to keep your parts functional and durable. Follow SLS guidance: minimum wall thickness ~0.7 mm, wire widths 1.0–2.0 mm, and clearances near 1.0 mm. Add escape holes ≥3–4 mm for reliable powder removal in internal cavities.

Wall thickness, wires, and clearances for flexible geometries

Target walls that balance flexibility and fatigue life. Thin walls below 0.7 mm risk early failure; thicker regions add strength but reduce bendability.

Design slender features as wires 1.0–2.0 mm wide and avoid sharp transitions that concentrate stress. Keep clearances at about 1.0 mm for mating parts and assembly.

Designing for wear points: abrasion surfaces and tear stops

Place abrasion pads or sacrificial overlays where rubbing is expected. Use tougher grades at contact zones to increase resistance and life.

Add tear-stop radii and rounded notches at cutouts to stop crack propagation and extend service life.

Integrating TPU with metals and rigid plastics

Plan interfaces with bearings, Teflon-coated components, or press-fit inserts to reduce friction. Use mechanical interlocks or overmolding for secure joins, and allow for different thermal expansion in tolerance stacks.

Surface finish, post-processing, and assembly tips

Expect matte or slightly textured surfaces from powder systems and softer finishes from printing. Light sanding, bead blasting, or vapor smoothing can improve feel but may change tolerances.

For assembly, prefer wide bearing areas, avoid thin tabs under load, and use compliant fasteners or captive clips to prevent creep and tear in service.

Key Applications of TPU Plastic Across Industries

Real-world projects rely on flexible materials where impact absorption and abrasion resistance cut downtime and warranty claims. Below, you’ll see how key properties map to parts and outcomes across major industries.

Industrial components

Use these materials for gaskets, seals, tubing, caster wheels, and cable guides. Abrasion resistance and chemical resistance reduce failures in harsh environments.

Example: an SLS 90A cable guide at Heidelberger Druckmaschinen cut maintenance and protected cables from high friction.

Automotive products

For intake hoses, air ducts, trims, and vibration dampeners, choose mid‑hardness grades. Stratasys recommends FDM 92A for air ducts and vibration control where durability matters.

Medical and wearables

Applications include tubing, orthotics, and device components. Biocompatible grades give soft support and reliable performance for patient-facing parts.

Consumer and sporting goods

Footwear midsoles, cases, grips, and ski gear benefit from low-temperature resistance and colorable finishes. That lets you meet brand looks without losing function.

Selecting the right grade

Pick softer grades for cushioning and harder grades for load-bearing wheels or seals. Plan interfaces with bearings, liners, or fasteners to build durable assemblies.

How to Source High-Quality TPU Parts in the United States

Sourcing domestically gives you faster iterations, clearer compliance, and tighter control over quality. Start by matching your required volume and finish to the right process.

Choosing between FDM, SLS, and MJF

For quick prototypes, FDM printers provide fast turnaround and low cost. Expect visible layer lines and lower dimensional accuracy.

SLS is better for complex geometry and higher accuracy. Use the SLS rules: 0.7 mm minimum walls, 1.0 mm clearances, and escape holes for cavities.

MJF delivers near-isotropic properties and scales well for short production runs with consistent mechanical behavior.

Specifying Shore, chemistry, and finish

Write your RFQ with clear targets: Shore hardness (for example, 90A), chemistry family (polyester or polyether), and finish expectations.

Include target properties such as tensile, elongation, and abrasion resistance. Add inspection criteria and test coupons for tear and wear features.

When you reach out to manufacturers and companies, state volume, certification needs, and required lead times. Request pilot builds to validate tolerances and repeatability before full production.

Fecision: Your Reliable Partner for TPU Parts

You need a single source that guides design choices and delivers repeatable flexible parts at scale. Fecision teams pair engineering feedback with U.S.-based production so you move quickly from prototype to volume without surprises.

Prototype-to-production support with additive and traditional methods

We run FDM/FFF, SLS, and MJF so you can test deposition modeling and then scale on the best technology. TPU 90A powders and filaments enable impact-resistant components for many applications.

DFM feedback, material selection, and tight-tolerance manufacturing

Before you commit, our engineers give DFM advice on wall thickness, clearances, and tear stops. We help choose polyester, polyether, or aliphatic grades to hit strength, durability, and cosmetic goals.

Short lead times, consistent quality, and U.S.-focused service

Work with a domestic team that documents machine settings and first-article inspections. You’ll get predictable pricing, rapid lead times, and test plans that validate impact and long-term performance.

- U.S.-focused support from prototype to production.

- DFM and material guidance to reduce risk.

- Documented runs and QA for tight-tolerance builds.

- Clear communication for companies needing dependable supply.