The robotics industry is on the cusp of a revolution, driven by the demand for increasingly complex and precise components. As robotics applications expand across industries, from healthcare to manufacturing, the need for specialized components with consistent quality has never been greater.

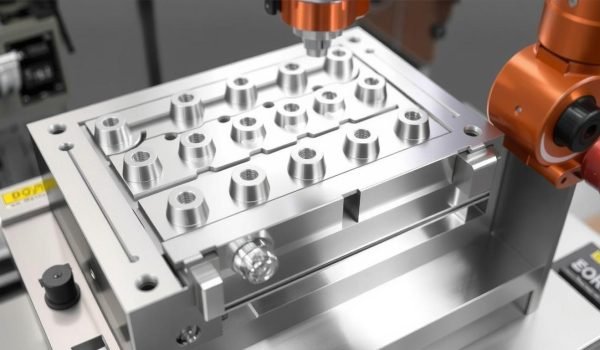

Precision mold tooling has become the backbone of modern robotics manufacturing, enabling the production of intricate molded parts with tight tolerances through advanced injection molding processes. This technology is crucial for creating components that balance durability, functionality, and weight considerations.

As you explore the future of robotics, understanding the relationship between design, tooling, and final performance is crucial.

The Evolving Landscape of Robotics Manufacturing

The robotics industry is on the cusp of a revolution, driven by advancements in manufacturing technology. As you explore the evolving landscape of robotics manufacturing, it’s clear that the demands for smaller, lighter, and more capable components are driving innovation in production techniques.

Current Challenges in Robotics Component Production

Traditional manufacturing methods often struggle with the complex geometries and tight tolerances required by modern robotics applications. Engineers face significant challenges in balancing structural integrity with weight reduction while maintaining the precision needed for reliable operation.

Why Precision Parts Matter for Next-Generation Robots

Precision parts directly impact a robot’s accuracy, repeatability, and overall functionality—factors that determine success in competitive markets. The integration of electronics within molded parts adds another layer of complexity to the manufacturing process, requiring advanced design considerations and specialized injection molding techniques.

Component miniaturization presents unique production challenges, requiring specialized injection molding techniques that can achieve micro-level precision. Material selection has become increasingly critical as robots operate in more diverse and demanding environments.

Understanding Precision Mold Tooling for Robotics

Precision mold tooling represents a critical intersection of engineering and craftsmanship in robotics manufacturing. To produce high-quality robotics components, it’s essential to understand the intricacies of precision mold tooling.

The Science Behind High-Precision Molding Processes

The science of high-precision molding involves careful control of multiple variables, including temperature, pressure, material flow, and cooling rates, all of which affect the final part quality. Modern tooling design incorporates sophisticated simulation techniques to predict and prevent potential issues before the physical mold is created.

Critical Quality Factors in Robotics Component Production

For robotics components, critical quality factors include dimensional accuracy, surface finish, internal stress distribution, and material homogeneity. Advanced molding experience enables the creation of complex features like undercuts, thin walls, and precise internal geometries that would be difficult or impossible with other manufacturing methods.

The manufacturing process for molded parts is complex, involving comprehensive manufacturability feedback and consultative design services to avoid mold design pitfalls. The production process is documented and optimized using scientific molding to ensure high-quality parts consistently and reliably with every production run.

Miniaturization: Enabling Smaller, Smarter Robots

Miniaturization is at the forefront of robotics development, enabling new applications from minimally invasive surgical robots to micro-drones and compact industrial automation. As robotics technology advances, the demand for smaller, more precise components is increasing.

Design Considerations for Micro-Components

Designing micro-components for robotics requires specialized knowledge of material behavior at small scales. Factors such as wall thickness, gate location, and material selection become critical in the injection molding design process.

Overcoming Challenges in Micro-Molding for Robotics

The injection molding process for micro-components must address challenges like filling small cavities and maintaining dimensional control. Advanced venting solutions and quality control measures are essential to prevent defects and ensure the production of high-quality plastic parts.

High-Density Parts: Maximizing Functionality in Limited Space

As robotics technology advances, the demand for high-density parts that can pack multiple functions into compact spaces is increasing. You are now able to create complex robotic systems that are not only smaller but also more efficient and reliable. High-density parts achieve this by integrating multiple components into a single, compact unit.

The benefits of high-density parts are numerous, including reduced assembly time and improved system reliability. By minimizing the number of components, you can also reduce the potential for mechanical failure.

Complex Geometries and Multi-Functional Components

Advanced injection molding techniques enable the creation of complex geometries and multi-functional components. You can now design parts with intricate features such as mounting points, cable routing, and sensor housings, all within a single component. This not only simplifies the assembly process but also enhances the overall performance of the robotic system.

Precision Tolerances for Interconnected Systems

Precision tolerances are critical when designing high-density parts for interconnected systems. You need to ensure that components mate correctly during assembly, maintaining the accuracy required for precise robotic movements. By achieving tight tolerances, you can guarantee the reliability and performance of your robotic systems.

Advanced Material Solutions for Robotics Applications

Advanced materials are revolutionizing robotics applications by providing unprecedented levels of strength, flexibility, and resistance to environmental factors. The selection of materials has become a critical differentiator in robotics performance.

Engineering-Grade Polymers for Durability and Performance

Engineering-grade polymers, such as PEEK, PEI, and liquid crystal polymers, offer exceptional strength-to-weight ratios, temperature resistance, and chemical compatibility. These high-performance plastics are ideal for demanding robotics applications where durability and performance are crucial. The injection molding process allows for the precise creation of complex geometries.

Composite Materials and Multi-Material Molding

Composite materials and multi-material molding techniques further expand the possibilities for robotics components. By incorporating materials like glass, carbon, or aramid fibers, manufacturers can enhance strength, stiffness, and dimensional stability. This approach enables the creation of complex parts with varied properties, supporting the development of more sophisticated robotic systems.

Molded Parts for End-of-Arm Tooling (EOAT)

Precision molded parts for EOAT are revolutionizing the robotics industry by enabling more complex and efficient robotic operations. End-of-Arm Tooling represents one of the most customized aspects of robotics design, with each application requiring specialized grippers, manipulators, or tools tailored to specific tasks.

Custom Grippers and Manipulators

Custom molded parts for EOAT offer significant advantages over machined components, including complex geometries and lighter weight. Injection molding services can produce grippers with integrated sensing features and conformal contact surfaces.

Lightweight Yet Durable EOAT Solutions

Lightweight yet durable plastic injection molded components reduce the inertia of robot movements, allowing for faster operation and reduced energy consumption. Material selection must balance wear resistance, impact strength, and weight considerations.

Quality Assurance in Robotics Component Manufacturing

To guarantee the performance and reliability of robotic systems, quality assurance is essential. This involves a comprehensive approach that encompasses design validation, first article inspection, and ongoing production monitoring.

First Article Inspection and Process Validation

The first article inspection process establishes a baseline for critical dimensions and characteristics, verifying that the manufacturing process can consistently meet design requirements. Advanced measurement capabilities, including coordinate measuring machines (CMM) and optical scanning, ensure accurate validation of complex geometries and surface finishes. Process validation confirms that the injection molding process parameters are optimized and stable, producing consistent parts across production runs.

Ensuring Consistency Across Production Runs

To maintain consistency, statistical process control techniques monitor key quality indicators throughout production. This allows for early detection and correction of potential issues before they affect part quality. Automated inspection systems integrated into the manufacturing process enable 100% verification of critical features without extending production time. By documenting critical-to-quality (CTQ) dimensions, the molding company can focus inspection resources on the features most crucial to the component’s success.

The Fecision Advantage in Robotics Mold Tooling

Fecision’s precision mold tooling services are revolutionizing the robotics industry with innovative manufacturing solutions. Their comprehensive approach integrates design expertise, advanced manufacturing processes, and rigorous quality control, offering a distinct advantage in robotics mold tooling.

Comprehensive Design-to-Production Capabilities

Fecision’s design-to-production capabilities streamline the development process, reducing lead times while ensuring that design intent is preserved throughout manufacturing. Experienced engineering teams work collaboratively with clients to optimize designs for both functionality and manufacturability.

Case Studies: Successful Robotics Applications

Fecision’s specialized knowledge in robotics applications allows them to anticipate challenges unique to this sector. Case studies demonstrate our success in solving complex manufacturing challenges for robotics clients, from micro-components for medical robots to durable custom plastic parts for industrial automation.

Fecision’s advanced tooling options, quality systems, and comprehensive services extend beyond basic molding to include prototyping, material selection guidance, secondary operations, and assembly services, simplifying the supply chain for robotics manufacturers.

Conclusion: Partnering for Innovation in Robotics Manufacturing

The rapidly evolving robotics landscape demands high-quality components, making the choice of molding partner critical. Fecision’s specialized manufacturing knowledge and extensive molding experience position them as an ideal partner for companies developing next-generation robotics solutions.

By choosing Fecision, you gain a collaborative team invested in your success. Their comprehensive molding services encompass the entire development cycle, from concept through prototyping to full-scale production, ensuring continuity and quality.

Partner with Fecision for custom plastic parts and tooling design services that meet your production needs, leveraging their expertise in plastic injection molding and commitment to precise surface finishes.