Gears are the backbone of industrial machinery and automotive systems, facilitating precise motion control and speed adjustments. With over 80% of mechanical power transmission systems relying on gears, their manufacturing process is crucial.

Gear hobbing stands out as the most widely preferred method for producing high-quality gears.This specialized machining process creates gear teeth with precision and accuracy, making it a cornerstone in industries demanding high quality gears. This guide will walk you through the complete process of gear hobbing, its benefits, and applications, providing valuable insights into one of the most efficient gear production methods available today.

What is Gear Hobbing

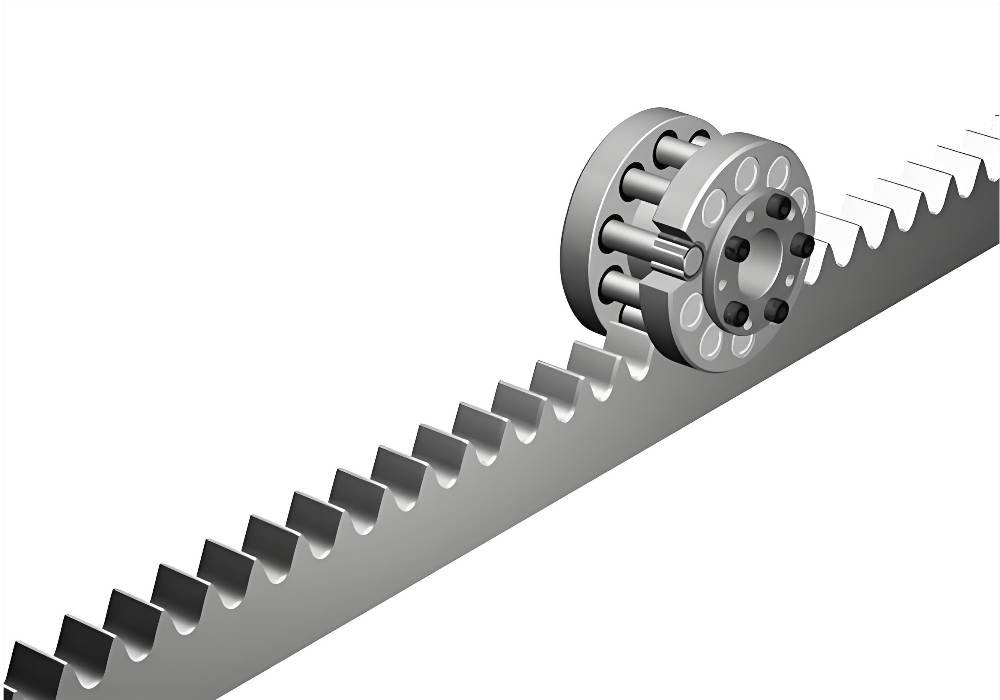

Gear hobbing is a highly efficient process used to cut gears, splines, and sprockets. It involves using a specialized cutting tool known as a hob, which rotates continuously while being fed into the workpiece to progressively carve out the gear teeth. This process can produce a wide range of gear sizes and shapes with high precision.

Today, gear hobbing has become a preferred method for manufacturing various gears, from small watch components to large industrial gears, thanks to advancements in CNC-controlled precision machines.

Modern advancements in hobbing technology, including multi-axis CNC controls and specialized cutting tools, have expanded the capabilities of this manufacturing process, making it remain relevant despite newer technologies.

The Gear Hobbing Process Explained

How Gear Hobbing Machines Work

Gear hobbing machines are specialized milling equipment that coordinate the rotation of both the workpiece and the hob cutter to generate gear teeth. The machine’s workholding fixtures, hob arbors, and precise drive mechanisms ensure accurate tooth generation. The hobbing process involves feeding the gear blank workpiece towards the hob until the desired depth is achieved, repeating the process until all teeth are formed.

The Role of Hobs in Gear Manufacturing

Hobs are critical cutting tools in gear hobbing, available in various types such as spur, chamfer, and helical. The design of the hob directly impacts the profile, accuracy, and finish quality of the produced gears. Proper hob selection is crucial based on specific gear requirements, including module size, pressure angle, and the number of teeth.

Key Parameters and Settings

Key parameters in gear hobbing include feed rates, cutting speeds, and depth of cut, which significantly affect the final gear quality. Modern CNC gear hobbing machines automate the process, allowing for precise control of these parameters and enabling quick changeovers between different gear specifications.

Gear Hobbing vs. Other Gear Manufacturing Methods

Gear manufacturing involves various techniques, including hobbing, milling, shaping, and broaching, each with its own advantages and limitations. Understanding these differences is crucial for selecting the most appropriate method for your specific application.

Gear Hobbing vs. Gear Milling

Gear hobbing and gear milling are both used to create gear teeth, but they differ significantly in their approach. Gear hobbing is a continuous cutting process that generates gear teeth using a hob, making it faster for large production runs. In contrast, gear milling uses a milling machine and typically involves more setup time but offers flexibility for custom or small-batch gear production.

Gear Hobbing vs. Gear Shaping and Broaching

Gear shaping is particularly useful for manufacturing internal gears or gears with shoulders that limit tool access, whereas gear hobbing is generally used for external gears. Gear broaching is another method used for producing internal gears and is known for its high precision and surface finish. While gear hobbing excels in high-volume production, broaching requires significant initial tooling investment.

5 Key Benefits of Gear Hobbing

Gear hobbing is a versatile and efficient method for producing high-quality gears.

Precision and Quality

Gear hobbing delivers exceptional precision and quality. Modern CNC hobbing machines achieve tolerances measured in microns, maintaining consistent quality across large production runs.

Speed and Efficiency

The process allows for multiple workpieces to be mounted on the same arbor for simultaneous processing, dramatically increasing production rates and making it a highly efficient method.

Versatility and Flexibility

Gear hobbing can create various gear types, from standard spur gears to complex helical, worm, and spline configurations, all with the same basic equipment.

Cost-Effectiveness

For medium to large production volumes, gear hobbing is cost-effective. The initial tooling investment is offset by faster production times and reduced labor costs.

Industries and Applications of Gear Hobbing

Automotive and Aerospace

The automotive industry relies on gear hobbing for transmission components and steering systems. In aerospace, hobbed gears are essential for aircraft engines and control systems.

Industrial Machinery

Hobbed gears form the backbone of power transmission systems in manufacturing equipment, heavy machinery, and renewable energy systems.

Types of Gears Produced

Gear hobbing can produce a wide range of gear types, including spur gears, helical gears, worm gears, sprockets, and splines, each used in various applications.

Conclusion

As manufacturing technologies continue to evolve, gear hobbing is adapting to meet the increasing demands for precision and quality. You’ll find that advancements in cutting tool materials, machine control systems, and automation capabilities are enhancing the efficiency and accuracy of gear hobbing processes. Emerging trends, such as dry cutting techniques and digital technologies, are also being integrated into modern gear hobbing, reducing environmental impact and improving production outcomes.

With ongoing research and development, gear hobbing is poised to remain a dominant method for precision gear manufacturing across multiple industries. Its ability to produce high-quality gears at a relatively low cost makes it an essential process in the automotive, aerospace, and machinery sectors. As you look to the future, it’s clear that gear hobbing will continue to play a vital role in modern manufacturing, delivering precision and quality that meets the evolving needs of various industries.