Can a material withstand extreme temperatures without losing its integrity? For industries working with high-heat applications, this question is crucial. Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, is a synthetic fluoropolymer that has revolutionized various industries with its unique properties.

With a melting point of 327°C (620°F), Teflon stands out for its ability to endure high temperatures. Understanding this characteristic is vital for manufacturers and engineers who work with this material in demanding environments.

This article will explore the factors affecting Teflon’s thermal behavior, different types of Teflon materials and their temperature ranges, and how these properties influence various applications. You’ll gain comprehensive insights into working effectively with Teflon in manufacturing settings.

Understanding Teflon: Composition and Properties

Chemical Structure of Polytetrafluoroethylene (PTFE)

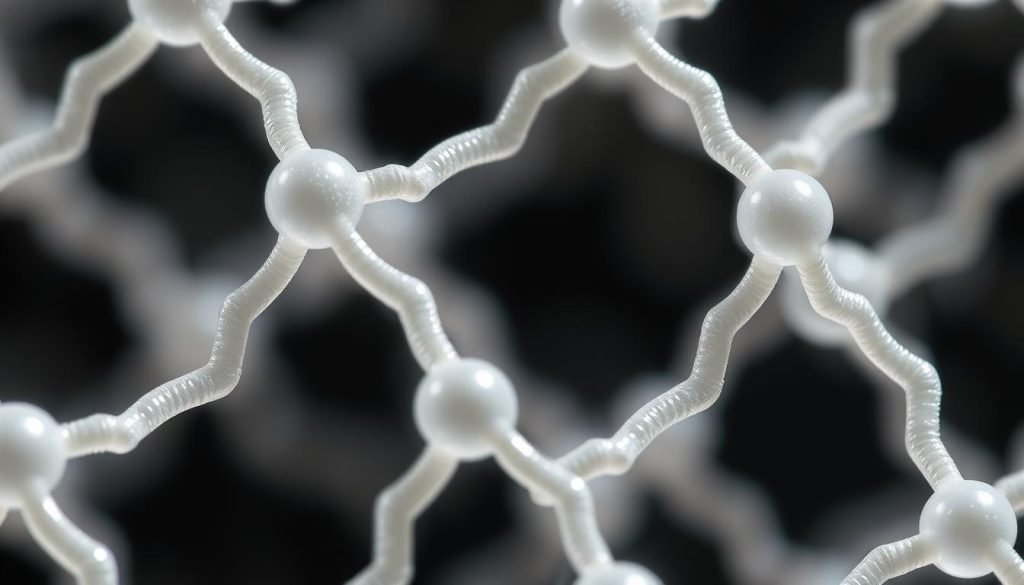

Chemically, PTFE consists of carbon atoms surrounded by fluorine atoms in a strong bond, creating an extremely stable polymer chain. This unique carbon-fluorine bond gives Teflon its remarkable resistance to heat, chemicals, and friction. As a fluorocarbon solid made entirely of carbon and fluorine, PTFE exhibits hydrophobic properties and is chemically inert.

Key Physical Properties of Teflon

Teflon’s unique properties make it ideal for various applications. It has one of the lowest coefficients of friction of any solid, making it perfect for non-stick applications. Additionally, Teflon’s physical properties remain stable across an exceptionally wide temperature range, and it is highly resistant to chemicals and heat. These characteristics have made Teflon a crucial material in cookware, industrial applications, and high-temperature environments.

The Teflon Melting Point: What You Need to Know

Understanding Teflon’s melting point is crucial for applications that involve high temperatures. Teflon, also known as PTFE (Polytetrafluoroethylene), has a melting point of 327°C (620°F), which is significantly higher than most other polymers and plastics used in manufacturing.

Standard Melting Point of PTFE (327°C/620°F)

The standard melting point of PTFE is 327°C (620°F). This high melting point allows Teflon to maintain its structural integrity and functional properties in extreme heat environments where other materials would fail. For instance, Teflon maintains high strength and self-lubrication at low temperatures down to 5K (-268.2°C) and good flexibility at temperatures above 194K (-79.15°C).

Difference Between Melting and Decomposition Temperature

It’s essential to distinguish between Teflon’s melting point and its decomposition temperature. While Teflon melts at 327°C (620°F), it begins to decompose at about 260°C (500°F) through 350°C (662°F), with complete pyrolysis occurring above 400°C (752°F). This distinction is critical for applications where Teflon is exposed to high temperatures for extended periods.

Thermal Behavior of Teflon Under Extreme Conditions

Under extreme thermal conditions, Teflon exhibits unique behavior. Unlike typical thermoplastics, Teflon doesn’t flow even when melted, maintaining an extremely high viscosity. At temperatures above 650-700°C, PTFE undergoes depolymerization. This characteristic, combined with its wide temperature operating range (from -268.2°C to its melting point), makes Teflon exceptionally versatile for applications requiring performance in both extremely cold and hot environments.

Different Types of Teflon and Their Melting Points

When it comes to Teflon, understanding its various types and their melting points is crucial for selecting the right material for your application. Teflon, a brand name for PTFE (Polytetrafluoroethylene), is available in different formulations, each with its unique characteristics.

Standard PTFE and Its Temperature Range

Standard PTFE, the original Teflon formulation, boasts a melting point of 327°C. It maintains its properties across an extremely wide temperature range, from cryogenic temperatures to its melting point. This versatility makes it suitable for various applications, from industrial processes to cookware.

Modified PTFE Variants and Their Melting Points

Modified PTFE variants have been developed to address specific application needs. These include versions with slightly lower melting points that offer improved processing characteristics. For instance, materials like PFA (perfluoroalkoxy alkanes) and FEP (fluorinated ethylene propylene) maintain many of Teflon’s desirable properties but have melting points in the 260-310°C range. The addition of comonomers like perfluoro(propylvinyl ether) and hexafluoropropylene can create branched structures that reduce crystallinity and lower the melting point, making these modified materials easier to process.

Comparing Teflon vs. Generic PTFE Temperature Properties

When comparing Teflon vs. generic PTFE temperature properties, it’s essential to understand that Teflon is simply a brand name for PTFE. There is no difference in the base material’s thermal properties. The variation lies in the formulation and processing, which can affect the melting point and other characteristics. Whether you’re using Teflon or generic PTFE, the temperature properties remain largely the same, ensuring consistent performance across different applications.

Factors Affecting the Melting Points of Teflon Materials

Several factors contribute to the melting points of Teflon materials, making it a complex property to predict. Understanding these factors is crucial for optimizing the performance of Teflon in various applications.

Molecular Weight and Chain Length Influence

The molecular weight and chain length of PTFE polymers significantly influence their melting points. Generally, higher molecular weight materials with longer polymer chains have higher melting points and greater thermal stability. This is because longer chains are more resistant to melting due to their increased entanglement and stronger intermolecular forces.

Impact of Additives and Fillers

Additives and fillers incorporated into Teflon formulations can either raise or lower the melting point depending on their nature. For instance, glass fibers may increase thermal resistance, while certain plasticizers might lower the melting temperature. The choice of additives and fillers is critical in tailoring the thermal properties of Teflon for specific applications.

Processing Methods and Their Effect on Melting Point

The processing methods used during Teflon production, including polymerization techniques, cooling rates, and pressure conditions, can alter the crystallinity of the material and consequently affect its melting point. Techniques such as cross-linking of PTFE molecules through radiation processing in an oxygen-free environment can enhance high-temperature mechanical properties and improve thermal stability.

How to Melt Teflon Material: Techniques and Considerations

The process of melting Teflon involves specialized techniques due to its distinct characteristics. Teflon’s high melting point and unique properties require careful consideration when processing.

Industrial Melting Processes for PTFE

Melting PTFE requires industrial processes that can handle its high melting point of 327°C. The most common method is sintering, where fine PTFE powder is compressed into a mold under high pressure (10-100 MPa) and then heated to 360-380°C to fuse the particles together. This process allows for the creation of complex shapes and parts.

Safety Precautions When Working with Heated Teflon

When working with heated Teflon, it’s crucial to observe strict safety precautions. Teflon can release toxic fumes if overheated beyond 260°C, potentially causing polymer fume fever in humans. Proper ventilation and temperature control are essential to mitigate these risks.

Common Challenges in Melting and Processing PTFE

One of the significant challenges in processing PTFE is its high viscosity even when heated to its melting point. This makes traditional injection molding difficult. Alternative processing methods include paste extrusion, ram extrusion, and isostatic molding, which can help overcome these challenges.

By understanding the techniques and considerations involved in melting Teflon, manufacturers can effectively work with this versatile material, leveraging its unique properties for various applications.

Teflon’s High Melting Point: Advantages in Various Applications

The high melting point of Teflon is a critical factor in its widespread use across different industries. This characteristic allows Teflon to maintain its properties under extreme temperature conditions, making it an ideal material for various applications.

Heat Resistance in Cookware and Kitchen Applications

Teflon’s high melting point makes it particularly suitable for non-stick cookware applications. Cookware coated with Teflon can withstand the high temperatures of cooking, typically between 200-260°C, without degrading or releasing the coating. This heat resistance ensures that non-stick pans and kitchen tools remain durable and safe for use.

Industrial Benefits of PTFE’s Thermal Stability

In industrial settings, PTFE’s thermal stability enables its use in high-temperature environments, such as chemical processing equipment. Here, it can handle corrosive substances at elevated temperatures without breaking down. This property makes PTFE an essential material in industries where equipment is exposed to extreme conditions.

Aerospace and Automotive Applications Requiring High Temperature Resistance

The aerospace industry relies on Teflon’s ability to maintain its properties at extreme temperatures, using it in aircraft components, space vehicles, and satellites. Similarly, automotive applications benefit from PTFE’s high melting point in components near engines and exhaust systems, where temperatures can fluctuate dramatically. In both industries, Teflon’s thermal stability is crucial for ensuring the reliability and performance of critical components.

Comparing Teflon’s Melting Point to Other Fluoropolymers

Teflon’s melting point is a key factor in its selection for various industrial applications, but how does it compare to other fluoropolymers? You need to understand these differences to choose the right material for your specific needs.

PTFE vs. FEP

PTFE has a melting point of 327°C, while FEP has a lower melting point of approximately 260°C. Although FEP offers better melt-processability, PTFE’s higher melting point makes it more suitable for high-temperature applications.

PTFE vs. PFA

PFA combines many of PTFE’s excellent properties with a melting point of around 305°C. PFA also offers improved flow characteristics when melted, making it suitable for complex molded parts.

PTFE vs. ETFE

ETFE has a significantly lower melting point of about 270°C but offers superior mechanical strength and abrasion resistance compared to PTFE. ETFE is often used in applications where these properties are critical.

When comparing fluoropolymers, it’s essential to balance their melting points against other properties such as chemical resistance, mechanical strength, and processability to meet specific application requirements.

Limitations and Challenges Related to Teflon’s Melting Point

Teflon’s melting point, although advantageous in many ways, also introduces several challenges. You need to understand these limitations to effectively work with this material.

Processing Difficulties

One of the primary challenges with Teflon is its high melting temperature of 327°C (621°F), which is above its decomposition temperature. This creates a narrow processing window that requires specialized equipment and techniques. The fact that molten PTFE maintains an extremely high viscosity means it doesn’t flow like conventional thermoplastics, making traditional injection molding nearly impossible.

Thermal Decomposition Concerns

When Teflon is heated near or beyond its decomposition temperature (around 260°C through 350°C), it can release toxic fluorinated gases. These gases pose serious health risks, including polymer fume fever, a condition similar to metal fume fever. You must take safety precautions when working with heated Teflon to mitigate these risks.

Environmental and Health Considerations

The persistence of PTFE and related substances in the environment raises concerns, as these materials don’t naturally degrade and can accumulate in ecosystems around the world. Historically, the production of PTFE involved chemicals like PFOA, which has been linked to health concerns. Although manufacturers have developed alternative processing aids, environmental implications remain a consideration.

In conclusion, while Teflon’s non-stick coating and high melting point offer many benefits, they also present significant challenges in processing, thermal decomposition, and environmental impact. Understanding these limitations is crucial for the safe and effective use of Teflon materials.

Innovations in Teflon Technology: Improving Thermal Properties

As Teflon technology continues to evolve, innovations in thermal properties are being explored. You are witnessing significant advancements in PTFE formulations that enhance its already impressive thermal stability. The brand name Teflon, synonymous with non-stick coatings, is now at the forefront of high-performance applications.

Recent Advancements in PTFE Formulations

Recent advancements in PTFE formulations have focused on enhancing its thermal properties through techniques like radiation cross-linking. This process creates stronger bonds between polymer chains, improving high-temperature mechanical stability. Electron beam processing has emerged as a valuable method for modifying PTFE, creating cross-linked structures that maintain their integrity at extreme temperatures. These modified materials are ideal for applications where conventional PTFE would lose strength.

The development of PTFE nanocomposites, incorporating materials like carbon nanotubes or ceramic particles, has produced variants with improved thermal conductivity. These materials maintain the low friction coefficient that makes PTFE widely used in various industries.

Future Trends in High-Temperature Fluoropolymers

Researchers are exploring new copolymers and blends that preserve PTFE’s beneficial properties while addressing its processing challenges. Future trends point toward environmentally friendly processing methods that eliminate the need for potentially harmful additives. These advancements will continue to make PTFE useful across numerous applications, from cookware to aerospace, where its thermal stability and chemical resistance are invaluable.

These innovations ensure that Teflon remains a critical material in high-temperature applications, making it an ideal choice for industries that require high-performance fluoropolymers.

Conclusion: The Significance of Teflon’s Melting Point in Modern Applications

With its melting point at 327°C, Teflon PTFE stands out as a crucial material in modern manufacturing. The Teflon ,known for its non-stick properties, has revolutionized various industries, from cookware to aerospace technology. The unique combination of high melting point, chemical resistance, and ultra-low friction makes Teflon PTFE an irreplaceable material in countless applications.

Understanding Teflon’s melting point and thermal behavior is essential for engineers and manufacturers to leverage its full potential in next-generation products.

FAQ

What makes Teflon non-stick?

Teflon’s non-stick properties are due to its low friction coefficient and its inertness to most substances, making it an ideal material for cookware and other applications.

Is Teflon safe for use in cookware at high temperatures?

While Teflon is generally safe for cookware, it’s not recommended to heat it above 250°C (482°F) as it can release toxic fumes. Always follow the manufacturer’s guidelines for safe usage.

What are some common applications of Teflon beyond cookware?

Teflon is used in various industrial and commercial applications, including aerospace, automotive, and medical devices, due to its high temperature resistance, chemical inertness, and low friction properties.

Can Teflon be recycled?

Recycling Teflon is challenging due to its high melting point and chemical inertness. However, some companies are developing methods to recycle PTFE, and it’s worth exploring these options for sustainable practices.

What are the benefits of using Teflon in industrial applications?

Teflon’s benefits include its high temperature resistance, chemical inertness, and low friction coefficient, making it an ideal material for various industrial applications, including seals, gaskets, and linings.