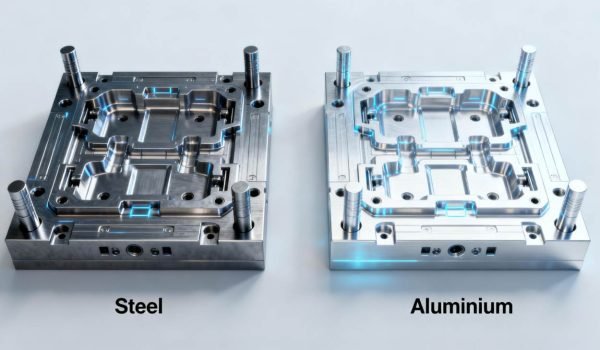

The decision between using aluminum vs steel injection molds is the hidden profit lever in your plastics project, as efficiencies in cycle time have a dramatic effect on your unit cost. This guide will clarify the core differences, from thermal performance and wear resistance to cost curves and machining practices. You need this insight to make the right tooling decision.

Why Need Aluminum or Steel Mold for Injection Molding?

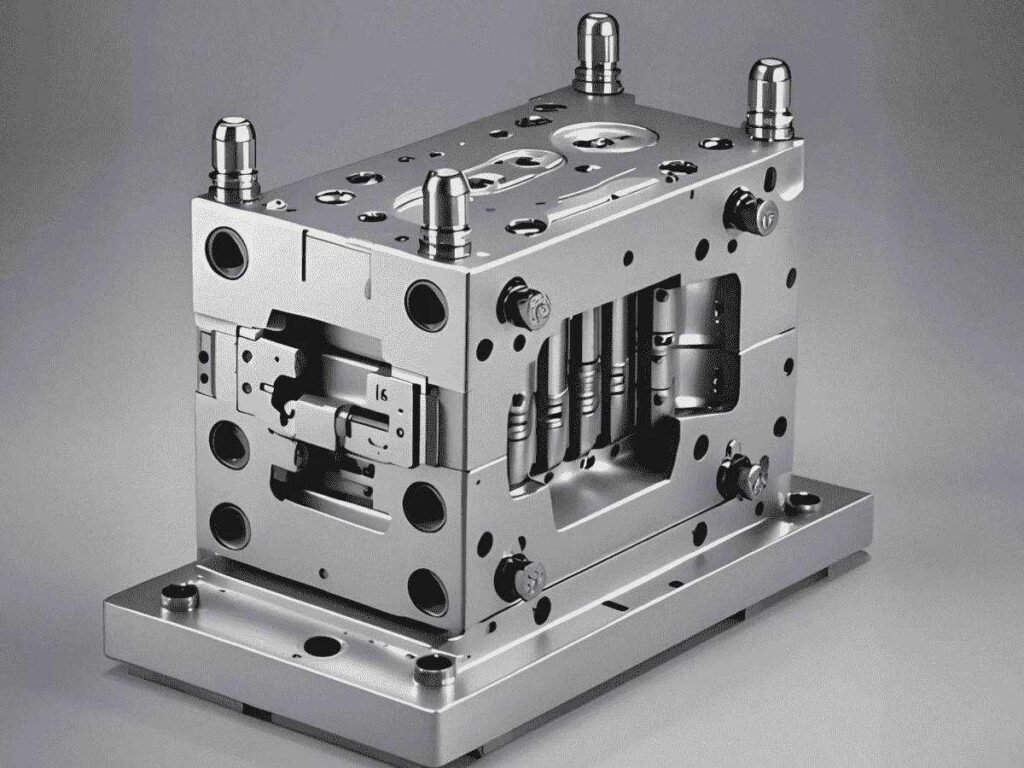

Molds are the negative geometries that define the contours of your finished plastic part. They must withstand immense pressure from the molten polymer and quickly pull away the heat for solidification. Without this crucial function, the plastic simply cannot solidify precisely into the exact engineered tolerances your design demands.

In order to facilitate high volume production, the aluminum and steel molds must meet the minimum requirements to run adequately. They provide hardness, thermal conductivity, and corrosion resistance – all must be in place to operate. This strength ensures that your injection cycles can repeat millions of times without the critical cavity surface degrading or eroding.

The economic justification is straightforward: using precisely machined metal guarantees a superior finish straight from the tool. This naturally smoother surface is vital because it effectively eliminates expensive secondary finishing operations like sanding or buffing, dramatically cutting down your overall unit cost.

Steel vs. Aluminum Injection Molds: Key Differences

Now that you understand the basic function, we can dive into the specifics. The main differences boil down to how each metal handles heat, pressure, and long-term use.

Durability & Wear Resistance

Whether you are using hardened steel like H-13 or S-7, the tempered metal can last for hundreds of thousands and possibly millions of shots. This massive steel lifespan holds true even if you run highly aggressive resins, such as glass-filled nylon, giving you extreme reliability for high-volume jobs.

In contrast, aluminum molds (QC-10 or 7075-T6) typically peak in the low- to mid-five-figure shot range. The abrasive resins impact aluminum faster, with galling appearing sooner because its protective oxide layer is softer. You must apply a hard coating if you process high-fiber-load materials like PEEK.

Thermal Properties

The massive conductivity gap is the biggest difference, as aluminum 7075 is several-fold more conductive than P20 steel. This speed advantage means aluminum reaches its typical steady-state temperature noticeably sooner, providing a quicker heat-up transient and saving you valuable machine warm-up minutes.

This efficiency also impacts your bottom line by reducing your total energy consumption. Faster thermal equilibration trims the required duty cycle of your barrel heaters. This translates directly to a lower overall kilowatt-hour consumption per part you manufacture, saving money on every shot.

Surface Finish

An aluminum cavity that has been precisely milled at high speed often delivers a slightly smoother as-milled roughness than steel under the same cutter. However, while both metals can reach the top polishability ceiling (SPI A-1), aluminum tends to clog felt polishing bobs faster, increasing labor time.

Furthermore, you will notice that the surface gloss retention on aluminum parts tends to decline sooner during production. Steel molds for plastic injection are much better at consistently holding the required specification through many more production cycles, making them superior for long-term aesthetic demands.

Heating & Cooling Time

Cooling simulation results are dramatic, clearly showing that a part cools noticeably faster in an aluminum tool. This rapid heat removal can trim several seconds off your molding cycle, drastically increasing throughput and reducing the thermal stress on your part.

This speed improves efficiency by reducing your chiller load, which can potentially downsize your auxiliary equipment. Crucially, aluminum inserts also tend to show a smaller temperature spread, offering a better uniformity factor that influences warpage behavior.

Impact on Molding Cycle Time

Real-world benchmark tests consistently show that parts like two-cavity polypropylene boxes cycle quicker in aluminum than in steel. This direct increase in speed significantly translates to a higher annual output on the same press hours, fundamentally boosting your capacity.

This extra throughput ROI is essential because the money you earn from the additional parts per year can quickly pay for the tool. Depending on your profit margin, the total return on investment for the aluminum tool usually happens within just a few months.

Defect Reduction

Aluminum’s superior thermal management provides immediate quality benefits by reducing common defects. A more even temperature distribution lowers the depth of sink marks in your parts, directly improving surface quality compared to steel molds for plastic injection.

Furthermore, the fast heat removal keeps the melt below its degradation temperature, helping to eliminate surface defects like blush & burn marks. The highly uniform fill front also creates a stronger weld-line strength in complex engineering blends like PC/ABS.

Quick-Look Comparison Table

To summarize the key differences quickly, here is a reference table for you.

| Comparison Criteria | Aluminum Molds | Steel Molds |

| Durability & Lifespan | Short (10,000s) | Long (1,000,000s+) |

| Wear Resistance | Low | Very High |

| Thermal Conductivity | Very High | Low |

| Energy Consumption | Lower | Higher |

| Initial Surface Finish | Excellent | Good |

| Long-Term Finish | Degrades Faster | Consistent |

| Heating/Cooling Speed | Very Fast | Slow |

| Cycle Time | Shorter | Longer |

| Sink Marks & Warpage | Less Prone | More Prone |

| Burn Marks & Defects | Reduced Risk | Higher Risk |

| Upfront Cost | Lower | Higher |

| Lead Time | Shorter | Longer |

Advantages and Disadvantages of Aluminum and Steel Injection Molds

Both choices have associated pros and cons that need to be addressed. Here we will summarize the key points of each alternative prior to you making a final choice.

Pros of Aluminum Molds

The biggest plus is the low up-front cost. Shorter CNC machining time and no mandatory heat treatment process result in a cheaper tooling invoice. This makes aluminum an excellent and less expensive option for start-ups and low-volume projects.

Aluminum also allows for quick design iterations due to its soft nature and improves machining efficiencies. Furthermore, the lightweight handling means easier crane loads and faster mold swaps, saving your team time in the production area.

Cons of Aluminum Molds

A major drawback is the limited high-temp range; you cannot process resins that melt far above aluminum’s operating limits without risking damage. Another concern is wear under fillers like glass fiber, which requires expensive protective coatings to save the parting line.

Additionally, aluminum suffers from dimensional creep due to its higher thermal expansion coefficient. This means the cavity size changes more per degree of heat, potentially risking shut-off variation over long production runs.

Pros of Steel Molds

Steel offers extreme longevity, with high-quality H-13 cavities remaining in excellent service far beyond the six-figure shot count. They are the true workhorses, providing reliability for high-volume, long-term programs.

Their excellent broad material compatibility means steel can process nearly every resin, including highly abrasive grades. This rigidity provides fine-feature stability, maintaining micro-rib accuracy and sharp edges over exceptionally long runs.

Cons of Steel Molds

The chief disadvantage is capital intensity; the high up-front cost is multiple times that of aluminum, tying up valuable cash. This choice also means a longer lead-time because heat treatment and multiple finishing steps extend the required calendar weeks.

You must also account for heavy maintenance. Welding hardened steel requires time-consuming pre-heat and post-heat operations to prevent cracking, consuming many more maintenance hours compared to aluminum repairs.

Steel vs. Aluminum Injection Molds: Which One to Choose

With the pros and cons in mind, how do you make the right choice for your project? Consider these essential factors to guide your decision-making process.

Production Volume & Economics

Your annual volume dictates the tool’s expected lifespan. Low-volume production tends toward aluminum for financial savings, while high-volume runs easily justify the higher cost of durable steel. For mid-volume projects, always run a detailed cost modeling report.

Part Complexity & Structural Demands

For parts requiring superior structural integrity, such as those with ultra-thin shut-offs or complex angles, steel is safer. The superior rigidity of steel makes it a more reliable choice than softer aluminum for parts that involve internal features or unscrewing cores.

Resin Compatibility & Wear

Always verify your resin selection against the mold material’s wear resistance. If you plan to use high-temperature, highly abrasive, or demanding optical grades of resin, this frequently mandates the use of steel. Aluminum cannot handle that level of heat and wear.

Budget & Cash-Flow

The initial cost difference heavily favors aluminum when your capital budget is constrained. The upfront cost of steel is significantly higher. If you decide you must have steel, exploring financing options may help bridge that initial investment gap. Understanding aluminum vs steel injection molds costs is critical to your final choice.

Project Timeline Urgency

When you face severe timeline pressure—such as for crowdfunding builds or quick pilot runs—aluminum’s speed is non-negotiable. The rapid manufacturing time of aluminum molds for injection molding can save you critical weeks compared to the longer lead time required for steel.

Dimensional & Tolerance Needs

For projects requiring the tightest long-term dimensional and geometric tolerance needs, selecting steel is the safer choice. Steel provides a much more stable molding environment over millions of cycles, ensuring your part consistency remains high.

Conclusion of Section

Pick aluminum when your concerns are speed, lower initial spend, and five-figure shot counts. Choose steel when million-shot durability, aggressive resins, or micro-features outweigh the higher first cost. Map these factors to multiply your project’s margin.

How to Manufacture Aluminum or Steel Injection Mold

Once you’ve selected your metal, the manufacturing process begins. The way the mold is machined and finished varies greatly depending on whether you choose aluminum or steel.

CNC High-Speed Machining

Aluminum practice uses high rotational speeds and a light chip load to quickly deliver a near mirror-like finish, potentially saving you hours of hand polishing. In contrast, steel practice often involves hard milling with specialized cubic-boron-nitride inserts and lower RPMs, which is designed to save expensive electrical discharge machining (EDM) time.

EDM Sinker & Wire

Electrical Discharge Machining (EDM) is needed for features that are simply beyond a standard cutter’s reach, such as sharp internal corners or deep, small-diameter ribs. When used on steel, the resulting recast layer is thicker and must be stoned off, but the aluminum recast layer is thinner, making its post-processing quicker.

Additive and Hybrid Approaches

One cutting-edge technique is conformal cooling, which uses printed steel inserts containing curved, optimized cooling channels. These inserts can be placed into an aluminum master to dramatically cut cycle percentages. Alternatively, rapid aluminum prototypes can be built in days using laser-bed technology, with infiltration processes boosting the material’s hardness quickly.

Post-Processing & Assembly

Upon completing all the metal work, the last processes are extremely important to finalize the tool. This post-process includes welding any components you need to assemble, fine-polishing the cavity surface of the molds, and of course, the precise installation and fitting of slides, ejectors, and other complex mechanisms.

Suitable Maintenance Practices for Aluminum and Steel Molds

For the longest possible mold lifespan, correct maintenance is key. This involves using specific cleaning and repair procedures for each metal type, along with damage-free storage.

Daily Cleaning

If your mold is aluminum, you must use brass brushes that are non-abrasive with neutral detergents, and be really careful never to use a caustic or harsh chemical, as it could chemically attack the softer surface of the aluminum. If your mold is steel, you can simply use a nylon brush with a little light oil to clean the surface of the mold to remove the corrosive deposits.

Scheduled Inspection

You should inspect the parting-line wear on aluminum molds for injection molding much more frequently due to the softer metal. For steel, you can accept extended inspection intervals. Always focus on measuring the clearance of your ejector pins during checks; excess play or scoring signals that the pin bushings need renewal to maintain crucial part quality.

Corrosion Protection

Aluminum should be stored under moderate humidity. You should always wrap them in a VCI (volatile corrosion inhibitor) film to prevent moisture from attacking the aluminum surface. Steel mold faces should be covered thoroughly with lithium grease, and all water lines should be plugged. This prevents any residual moisture from causing internal rust and damage.

Repair Techniques

To repair aluminum, you use TIG welding with a matching filler rod. This process requires controlled pre-heating according to a specified schedule. After welding, the part needs an aging treatment to bring its strength back. For steel repairs, the specialized process of laser cladding is often used. This method rebuilds the surface hardness using a matching-grade powder without causing distortion to the surrounding steel.

Conclusion

Choosing between aluminum vs steel balances thermal speed against wear endurance, and upfront dollars against pennies-per-part cost. Pick aluminum when speed and cash-flow relief for low-volume programs are key. Select steel when you need million-shot durability, aggressive resin processing, or the finest micro-feature stability to multiply your long-term margin.

Need the decision fast? Fecision’s engineering excellence ensures you get the right tool, whether it’s rapid aluminum molds for injection molding or durable steel molds for plastic injection. We offer both Rapid Tooling for low-volume needs and Production Tooling for millions of shots, and we run conductivity simulations and strategically select materials to balance performance, longevity, and your budget – from P20 steel to Aluminum alloys.

Our engineering team is specialized, and you get 15+ years of experience providing optimal performance and quality molds. Cost efficiencies will come from optimized design and modular design, with a reliable 98% on-time delivery. Contact Fecision to start your project now!