The mold design is the most crucial choice you will make when you begin planning your injection molding project. Your production cost, lead time, and quality will all be directly impacted by your decision between a single cavity mold and a multi-cavity mold. You risk wasting time and money if you choose the incorrect option.

To make an informed decision, you must be aware of the main distinctions. This guide explains the meaning of each type of mold, its advantages and disadvantages, and the most important considerations to make before making a decision. You will be able to determine which mold best suits your needs by the end of the process.

What Is A Single Cavity Mold?

There is only one cavity in a single cavity mold. It implies that one part is produced during each injection cycle. This type of mold is frequently used for prototype parts or low-volume production. When you require high accuracy but don’t need thousands of pieces immediately, it works well.

Key Advantages

A single cavity injection mold’s primary advantage is its ease of use. Because the design is simpler, the tooling cost is lower. Additionally, maintenance is simpler, and modifications can be made fast. Because fewer parts are produced at a time, you also lower the chance of quality problems.

Challenges and Limitations

However, for large projects, a single cavity mold is slow. Since you receive only one piece per cycle, your cost per part increases. This type of mold is not the best option for mass production.

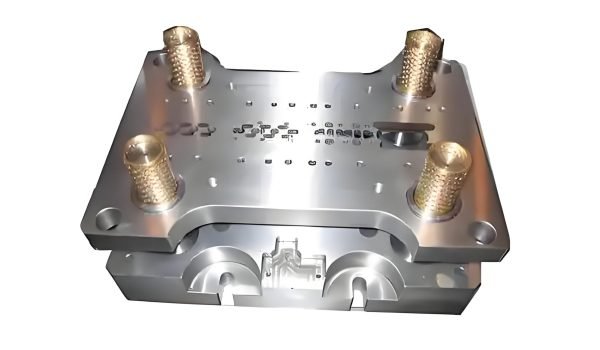

What Is A Multi-Cavity Mold?

Two or more cavities are contained within a single tool in a multi-cavity mold. It enables you to use a single injection cycle to create multiple parts. In large-scale manufacturing, where cost and speed are crucial factors, multi-cavity molds are commonly employed.

Key Advantages

High output is a primary advantage of a multi-cavity mold. This mold saves time and lowers the cost per part if you need thousands of parts quickly. You can produce more parts simultaneously by adding more cavities. Multi cavity mold manufacturers create these molds for use in consumer goods, medical devices, and automobiles.

Challenges and Limitations

Multi cavity mold design is expensive and complicated, though. Your initial cost will be high. Because each cavity needs to be built to exacting tolerances, it also takes longer to build. Compared to a single-cavity mold, maintenance is more challenging. The entire mold may be impacted if one cavity is damaged.

Soft plastic molds with multiple cavities are widely used for consumer goods and packaging. They are quick and effective, but for the best results, it’s essential to work with a skilled supplier.

Single Cavity vs Multi Cavity Mold: Key Differences

| Aspect | Single Cavity Mold | Multi Cavity Mold |

| Number of Cavities | One cavity | Two or more cavities |

| Production Speed | Slow, one part per cycle | Fast, multiple parts per cycle |

| Initial Tooling Cost | Lower | Higher due to complex design |

| Cost per Part | Higher for large quantities | Lower for high-volume production |

| Lead Time | Shorter for tool manufacturing | Longer because of the complex mold design |

| Maintenance | Easy and less costly | Harder and more expensive |

| Best For | Low-volume or prototype production | Mass production and consistent quality |

If you only need 1,000 parts, a single cavity mold works well. If you need 100,000 parts, a multi cavity mold is the clear choice.

Factors To Consider Before Choosing

Your choice depends on several factors:

- Production Volume: Select a single cavity mold if you require prototypes or small quantities. Use multi-cavity molds for high-volume production to save money and time.

- Budget: The initial investment for a multi-cavity mold is higher. A single cavity mold is safer if money is tight.

- Part Complexity: A multi-cavity mold is a good choice if your part design is straightforward. Single cavity molds provide superior control for intricate parts.

- Lead Time: Manufacturing multi-cavity molds requires a longer lead time. A single cavity mold may start more quickly if you need parts right away.

- Quality Requirements: Consistency is provided by multi-cavity molds, but only when they are created by skilled mold manufacturers specializing in multi-cavity molds.

Mention how CNC machining and precision affect mold accuracy.

Which One Should You Choose?

Use a single cavity injection mold if you want to test your design or only need a small quantity. It is less expensive and simpler to modify.

A multi-cavity mold is the best choice if you intend to produce thousands or even millions of parts. Although the initial cost is higher, the total cost per part drops significantly. Multi-cavity molds are perfect for businesses that require reliable and quick production.

Always keep your long-term objectives in mind. In certain cases, making a larger upfront payment can result in significant future savings.

How Fecision Supports Your Mold Needs

Fecision is aware of the crucial role mold selection plays in your company. For this reason, depending on the needs of your project, we provide both single-cavity and multi-cavity molds.

Precision CNC machining and the creation of custom molds are our areas of expertise. Our team has experience creating single cavity molds for prototypes or small batches, as well as multi-cavity mold designs for high-volume production.

Additionally, we offer sophisticated multi cavity soft plastic molds for packaging and consumer goods. Strict quality checks are performed on each mold we create to guarantee precision and longevity.

Working with Fecision entails receiving knowledgeable guidance, prompt delivery, and reliable support. We help you select the best option to ensure your production remains timely and economical.

Conclusion:

Depending on your volume, budget, and schedule, you can choose between a single cavity mold and a multi-cavity mold. For testing or small runs, a single cavity mold works best. For large-scale production and reduced part costs, a multi-cavity mold is an ideal solution.

Consult with a qualified team if you’re still unsure. For successful injection molding, Fecision offers the direction and caliber you require. We are here to help you achieve your production goals because they are important.