Are you aware of the versatile plastic material that’s used in everything from food packaging to automotive parts? This material has become a staple in modern manufacturing due to its unique combination of properties.

One of the most widely used plastics in the world today is a type of plastic that’s considered safe for food contact and is FDA-approved. Its durability and resistance to various chemicals make it a popular choice for numerous applications.

This comprehensive guide will explore the key benefits, different types, and common uses of this material, helping you understand why it’s a fundamental component in various industries.

What is Polypropylene?

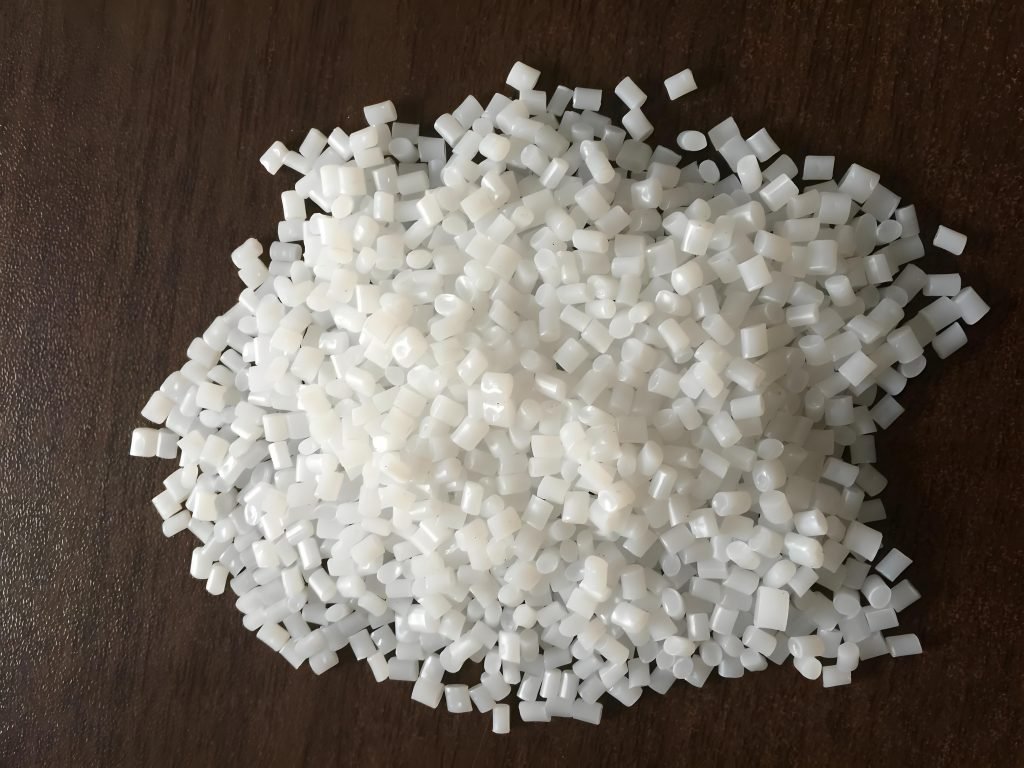

You might be familiar with polypropylene, a common plastic used in various products, but let’s dive deeper into what it is. Polypropylene is a thermoplastic polymer made from propylene monomers, belonging to the polyolefin group. It is known for being non-polar and partially crystalline.

Discovery and Development

The discovery of polypropylene dates back to the early 20th century. It was first discovered in 1951 by Karl Rehn and Karl Ziegler, who were working on catalysts for polymerization processes. Their work led to significant advancements in the production of polypropylene, making it a vital material in various industries.

Chemical Structure and Composition

Polypropylene consists of long chains of propylene monomers (C₃H₆) connected through a process called chain-growth polymerization, resulting in a semi-crystalline structure. The chemical composition features a methyl group (CH₃) attached to every other carbon atom in the backbone chain, significantly influencing its properties. The arrangement of these methyl groups, known as tacticity, can vary, leading to different forms such as isotactic, syndiotactic, and atactic polypropylene, each with unique material properties.

As a polyolefin, polypropylene shares chemical characteristics with polyethylene but offers enhanced rigidity and heat resistance due to its methyl side groups. The molecular structure allows it to be easily modified with various additives to enhance specific properties for different applications, making it a versatile material.

Key Properties of Polypropylene Plastic

Polypropylene’s versatility stems from its unique combination of physical and chemical properties. This makes it an ideal material for a wide range of applications, from consumer goods to industrial products.

Physical Properties

Polypropylene exhibits a range of physical properties that make it suitable for various uses. It has a relatively high melting point, typically between 160-170°C (320-338°F), allowing it to maintain its structural integrity at temperatures where many other plastics would deform.

The material also maintains its flexibility even at freezing temperatures, unlike some plastics that become brittle when cold. This property makes it suitable for freezer containers and cold-weather applications.

Chemical Resistance

Polypropylene is known for its resistance to various chemicals, which is a critical property for its use in packaging and other applications where it may be exposed to different substances.

Thermal Characteristics

One of the key thermal characteristics of polypropylene is its low thermal conductivity, making it an excellent insulator. This property explains its popularity in applications ranging from thermal underwear to hot food containers.

Additionally, polypropylene’s resistance to heat damage allows it to withstand microwave heating and hot-fill processes in food packaging applications. However, its thermal expansion rate is higher than some other plastics, which must be considered in applications where dimensional stability across temperature ranges is important.

Different Types of Polypropylene

When it comes to polypropylene, understanding its different types is crucial for selecting the right material for specific applications. Polypropylene is categorized mainly into two types: homopolymer and copolymer, each with distinct properties and uses.

Homopolymer Polypropylene

Homopolymer polypropylene is made from a single type of monomer, resulting in a material with high stiffness and strength. It’s often used in applications where rigidity is important, such as in packaging, automotive parts, and household goods.

Copolymer Polypropylene

Copolymer polypropylene, on the other hand, is produced by combining polypropylene with another monomer, typically ethylene. This results in a material with improved impact resistance. Copolymer polypropylene is further divided into block and random copolymers, each with its unique characteristics.

Random vs. Block Copolymers

The arrangement of the co-monomer units in copolymer polypropylene significantly affects its properties. In block copolymers, these units are arranged in regular patterns, providing excellent impact resistance while maintaining stiffness. You’ll find block copolymers used in products like industrial containers and automotive parts. In contrast, random copolymers have a more disordered arrangement, resulting in improved clarity and flexibility, making them suitable for applications requiring transparency, such as medical packaging.

Understanding the differences between these types of polypropylene is essential for manufacturers to choose the most appropriate material for their products, ensuring they meet the required properties and applications.

Advantages and Disadvantages of Polypropylene

When considering the use of polypropylene, it’s essential to weigh its benefits against its drawbacks. You should understand both the advantages and limitations to make informed decisions in your applications.

Benefits of Using Polypropylene

Polypropylene offers several benefits that make it a popular choice in various industries. Its cost-effectiveness and durability are significant advantages.

Cost-Effectiveness and Durability

You will find that polypropylene is less expensive to produce than many other plastics, making it an economical choice. Additionally, its durability ensures that products made from it can withstand wear and tear over time.

Safety and Chemical Stability

Polypropylene is known for its chemical stability, which makes it safe for use in food packaging and medical devices. You can rely on its inertness to prevent chemical reactions that might contaminate contents or cause product failure.

Limitations and Drawbacks

Despite its benefits, polypropylene also has several limitations and drawbacks. Understanding these challenges is crucial for mitigating their impact.

Processing Challenges

You may encounter difficulties when processing polypropylene due to its high melt viscosity. This can require specialized equipment and techniques to achieve the desired product quality.

Environmental Concerns

The environmental impact of polypropylene is a significant concern. It can persist in the environment for hundreds of years, contributing to plastic waste. However, it’s worth noting that polypropylene is technically recyclable, with a recycle code #5, although actual recycling rates vary.

The production of polypropylene from petroleum resources also has a considerable carbon footprint, contributing to greenhouse gas emissions. Moreover, microplastics from degrading polypropylene products have been found in marine environments, potentially affecting wildlife.

Common Uses of Polypropylene in Various Industries

You can find polypropylene in a wide array of products, from household items to automotive parts. Its versatility and range of properties make it a valuable material across different sectors.

Food Packaging and Containers

Polypropylene is commonly used in the food industry for packaging and containers due to its resistance to chemicals and ability to be easily molded into various shapes. It’s used for making microwave containers, yogurt cups, and bottle caps, ensuring food safety and durability.

Automotive Applications

In the automotive sector, polypropylene is utilized for various parts, including bumpers, interior trim, and battery cases, thanks to its lightweight, impact resistance, and cost-effectiveness. Its applications contribute to improved fuel efficiency and vehicle safety.

Medical and Healthcare Products

Polypropylene is used in medical devices and healthcare products, such as syringes, medical containers, and implantable devices, due to its sterilizability, chemical resistance, and biocompatibility. These properties ensure the safety and effectiveness of medical products.

Textiles and Consumer Goods

Polypropylene fibers are woven into various consumer goods, including rugs, carpets, and outdoor furniture, benefiting from its moisture-wicking properties and durability. In the textile industry, it’s used for sportswear and outdoor fabrics due to its ability to manage moisture and resist mildew. Consumer goods manufacturers appreciate polypropylene for its ability to be molded into complex shapes and its weather resistance, making it ideal for products like luggage, storage containers, and household items.

The diverse applications of polypropylene highlight its importance in modern manufacturing, from enhancing product durability to contributing to innovative designs across various industries.

Conclusion: The Future of Polypropylene in Modern Manufacturing

The future of manufacturing is closely tied to the ongoing development and application of polypropylene. As a versatile and cost-effective material, polypropylene continues to dominate the plastics market, with its applications expanding into new areas.

Innovations in polypropylene compounds and recycling technologies are driving its increased use in sustainable applications. The global polypropylene market is projected to grow significantly, driven by demand in packaging, automotive, and consumer goods sectors.

As environmental concerns grow, the industry is responding with more recyclable formulations and bio-based alternatives. You can expect polypropylene to remain a cornerstone material in the plastics market for years to come, balancing practical benefits with the need for more sustainable plastic solutions.