A slight variation in wall thickness can warp an injection-molded enclosure, potentially sinking the entire production budget. Smart plastic enclosure design is actually the hidden profit lever in every manufacturing project. Getting these important details correct saves you time, money, and ultimately assures the lasting success of your final product.

This guide will explain what injection molded enclosures are and why custom designs are crucial for success. You will discover some essential Design for Manufacturability (DFM) handles—wall stock, gates, ribs, draft, and more—that keep your expensive tooling process on track and deliver perfect, repeatable parts.

What Is Injection Molding Enclosure Design?

The scope of injection molding enclosure design involves shaping a hollow plastic shell that shields inner electronics from heat, dust, chemicals, or impact while always staying mold-friendly. You must account for electrical ratings and accurate component placement from the beginning.

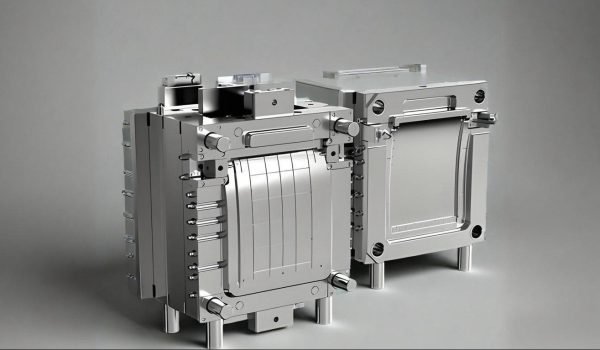

This process is the practice of creating a protective cover via high-pressure plastic injection. A successful injection molding plastic enclosure design relies on three core elements: the tool’s 3D cavity and core, which define the look; wall thickness, which controls cycle time; and assembly features like ribs and snaps, which form in one shot.

The resulting shell is far more than a generic part; it must precisely house PCBs, doors, and labels. Unlike simple brackets, these jobs demand tighter tolerances and strict UL fire ratings. This high level of integration requires expert Design for Manufacturability (DFM) to meet regulatory safety standards and ensure long-term field reliability.

Why Injection Molded Enclosures Are Important?

You may be wondering why injection molding is the unchallenged standard for modern device enclosures across every industry. The powerful answer lies in the unique blend of structural, safety, and clear economic advantages it provides your company.

High Strength-to-Weight Ratio

Thin-wall injection molded enclosures provide drop-proof protection for handheld scanners while being considerably lighter than other materials, such as metals, making long shifts more comfortable. This important strength-to-weight ratio is vital for all portable and wearable devices today.

You get strong, reliable defense against physical damage without adding unnecessary bulk or causing user fatigue. This enhanced durability significantly improves the overall lifespan and the essential user experience with the product.

Built-In EMI and IP Shielding

Electronic enclosure injection molding can easily blend conductive additives, effectively turning the plastic shell itself into a shield and successfully skipping time-consuming secondary plating steps. This integrated approach saves you valuable time and money on assembly later on.

It ensures that your final product meets necessary electromagnetic compatibility (EMC) standards effortlessly. The plastic shell does the job of two separate components, which simplifies the supply chain. You get a protective part that is highly functional right out of the mold.

Sterilization and Bio-Compatibility

USP Class-VI resins let injection molded medical enclosures face harsh gamma or autoclave cycles without crazing or degrading. This safeguards critical infusion pumps in sensitive critical care environments. You require materials that will withstand periodic harsh cleaning processes.

This is a crucial, non-negotiable requirement to achieve needed medical device regulatory approval and for the eventual longevity of the device. The right material will ensure complete patient safety and help the device function optimally during its sterile lifespan.

Rapid Scale Without Re-Tooling

From early pilot units to massive high volume orders, custom injection molded enclosures keep the exact same steel tool. Only the cavity count changes with your order volume. This means your revenue ramps much faster than slower, more complex sheet-metal fabrication routes.

This absolute stability in tooling ensures reliable, perfectly consistent parts from day one to the millionth unit without compromising quality. Injection molding effortlessly supports massive growth and allows you to scale your production quickly and efficiently when market demand increases.

Design Guide for Custom Injection Molded Enclosures

Now, let’s explore the essential design for manufacturability (DFM) principles. Following these ten critical guidelines ensures your custom enclosure moves smoothly from digital concept to physical, high-volume reality.

1. Wall-Thickness Management

Hold walls in the common 1.5–3 mm thickness band for amorphous resins. Go thinner for PP living hinges, and thicker for robust structural PC. Blend any steps with a gentle chamfer to hide the sink on highly cosmetic faces.

Consistency in wall thickness is absolutely vital to prevent warpage and unnecessary sink marks from forming on the surface. Make sure your design manages the transition between any thick and thin areas smoothly. This ensures the part cools evenly and quickly, which reduces your cycle time.

2. Rib and Boss Engineering

Rib width should be about half the wall thickness; height below three times the thickness for easy filling. Boss outer rings should be twice the screw diameter plus gussets for reinforcement. Proper engineering prevents pull-out under torque and adds necessary strength.

Ribs add immense strength without increasing the actual wall thickness, which saves material and time. Bosses are necessary for secure screw attachments. Careful engineering of these small features prevents breakage during assembly and under load.

3. Draft and Texture Strategy

For non-textured, smooth surfaces, a draft angle between 3° to 5° is typically sufficient for good part release. You must significantly increase this angle—often up to 8° or more—for heavily textured areas. This prevents the abrasive finish from clinging to the mold steel, ensuring that the injection molded enclosures eject without any unsightly scuff marks.

Without a sufficient draft, the part will firmly stick to the expensive mold tool. This causes inevitable damage and slow cycles. You must design for easy ejection to maximize production speed and prevent costly tool maintenance or downtime.

4. Corner Radii and Stress

The inside radius should be near half the wall thickness, with the outside radius matching the wall for uniform thickness. Rounded paths spread drop-shock energy efficiently and let melt sweep around bends without hesitation marks.

Sharp internal corners create stress points; these weak spots can crack under load or impact. Use radiused corners instead, as they spread stress evenly through the part. This simple change makes your design significantly stronger and more durable.

5. Gate Location and Flow Pattern

Hide submarine gates on ribs or bezel lips when feasible. Keep weld lines clear of critical features like living hinges. Simulate flow early so knit fronts meet away from vulnerable snap cantilevers. The material must fill all areas quickly.

Gate placement should be correctly made to minimize any visible marks on the cosmetic surfaces while also ensuring the plastic material evenly fills the entire molded cavity. Poor gate placement can create weak spots, warping, or surfaces that look unacceptable or require expensive rework or redesigns.

6. Parting-Line Placement

Run the parting line along a natural grip ridge or a dedicated gasket land for the best outcome. This crucial placement keeps flash invisible and prevents any flash from forming across an O-ring seat that would immediately breach the seal.

This precise alignment is vital for maintaining water and dust seals effectively across the enclosure’s life. The parting line is where the two halves of the mold meet. Smart placement ensures the resulting flash is either easy to trim or completely hidden.

7. Snap-Fit and Living Hinge

Cantilever snaps target low strain in ABS and require a tapered width at the base for maximum durability. Living hinges in PP near 0.3 mm thickness survive thousands of flexes for battery doors. These clever features integrate assembly right into the part.

This integration saves you significantly on hardware, such as screws, and reduces costly manual labor time. Designing them for minimal stress ensures they last for the product’s entire expected lifespan and function reliably, providing a satisfying user interaction experience.

8. Venting and Ejection

Vent depth should be shallow for quick-setting ABS, and slightly deeper for softer PP resins. Add small ejector pads on supporting ribs to stop white stress spots from forming during fast ejection. This prevents distortion.

Proper venting allows trapped air to escape as plastic fills the mold rapidly, which prevents unsightly burn marks and short shots. Ejection pads gently push the completed part out without warping the thin plastic walls or damaging the delicate surface finish.

9. EMI/ESD Integration

Conductive fillers or post-mold coatings effectively turn the plastic shell into a functional electromagnetic shield. Ground bosses align perfectly with PCB pads to dump RF energy in electronic enclosure injection molding projects quickly.

This protects your highly sensitive internal components from both electromagnetic interference and static discharge effectively. Integrating this protection directly into the plastic shell eliminates the need for bulky metal shielding or complex internal gaskets, saving you space.

10. Tolerance and Metrology

Apply commercial tolerances unless your part is mating with high-precision metal shafts. Record CpK data on critical PCB pockets to guarantee perfect screw alignment in multi-cavity tools consistently. Tighter tolerances are required for parts that connect to circuit boards.

Tighter control over part size is especially crucial for any components that interface with other non-plastic parts. This includes connecting to metal components or mounting a lens. You must specify these tighter zones clearly on your design drawings.

11. Prototype and Iterate

Print or machine soft tooling to accurately gauge snap force, gloss, and the final color before mass production. Tweak your design before committing to hardened steel to efficiently protect the injection molding plastic enclosure design budget.

Prototyping lets you physically test the fit and feel of your part and find and fix subtle problems early. This preventative approach saves you major downstream costs and schedule delays that would occur if problems were found late in the tooling process.

Conclusion

Following these structural and material guidelines is the best chance for success in high volume enclosure manufacturing. Using DFM principles early in your project helps guarantee part quality and long-term product reliability without extra effort.

Fecision excels in injection molded enclosure production by focusing on the tight tolerances critical for housing complex electronics. Our ISO-certified processes ensure the dimensional stability of critical features like snap-fits and bosses, which is essential for perfect PCB and screen alignment. We guarantee repeatable, high-precision parts, ensuring your electronic enclosures assemble flawlessly every time.

We combine advanced technology with value-added services such as surface coating (EMI shielding) and assembly. This way, you can be assured your custom injection molded enclosures achieve high standards for quality, function, and cosmetic appeal by the time they are delivered and ready for integration.

Ready to discuss your DFM challenges? Contact Fecision today for expert guidance on your custom enclosure design.