In 2022, a bioplastic called Polylactic Acid, or PLA, had the highest consumption volume of any bioplastic worldwide, accounting for around 26% of total bioplastic demand. This significant market share is a testament to PLA’s growing importance as a sustainable alternative to traditional plastics.

You might be wondering what makes PLA so popular. It’s produced from renewable resources like corn starch, making it an environmentally friendly option for various applications, from food packaging to medical implants and 3D printing.

As you explore the world of PLA, you’ll discover its unique properties, advantages, and limitations, and learn whether it’s the right material for your needs.

What is PLA Plastic?

PLA, or polylactic acid, is a thermoplastic polyester that is produced from fermented plant starch. You’re about to learn more about this versatile material and its production process.

Definition and Chemical Composition

PLA is a bioplastic made from repeating monomers with the chemical formula C3H4O2. It’s chemically composed of lactic acid molecules that are polymerized to form long chains, giving the material its unique properties. The chemical structure of PLA influences its properties, making it both biodegradable under certain conditions and suitable for various applications.

How PLA is Produced

The production of PLA involves several steps. First, starch is extracted from plants such as corn, sugarcane, or cassava roots. The starch is then converted into sugar through a process known as wet milling. The sugar is fermented to produce lactic acid, which is subsequently converted into lactide. Finally, the lactide is polymerized to create PLA. Most PLA is made from corn because it’s one of the cheapest and most available sugars globally.

Properties of Polylactic Acid

Understanding the properties of Polylactic Acid (PLA) is crucial for determining its suitability in various applications. You need to consider both its physical and mechanical properties to appreciate its value fully.

Physical Properties

PLA’s physical properties make it an attractive material for consumer products. Its density ranges from 1210-1430 kg/m³, and it often exhibits transparency and a natural glossy appearance. The glass transition temperature of PLA is between 60-65°C, while its melting temperature ranges from 130-180°C. These thermal properties significantly affect how PLA behaves during processing and use.

Mechanical Properties

PLA’s mechanical properties are between those of polystyrene and PET. It has good heat sealability but is very brittle, with less than 10% elongation at break. The material’s tensile strength is comparable to PET, but it has significantly less flexibility and impact resistance. You can modify PLA’s properties through additives, blending with other polymers, or processing techniques to enhance its performance for different uses.

Advantages and Disadvantages of PLA

Understanding the pros and cons of PLA is crucial for determining its suitability for various applications. PLA plastic offers several benefits, making it an attractive alternative to traditional plastics.

Benefits of Using PLA

PLA requires 65% less energy to produce than petroleum-based plastics and emits 68% fewer greenhouse gases. As a bio-based material derived from renewable agricultural resources, PLA is a sustainable choice. It’s also biodegradable under industrial composting conditions, breaking down into harmless lactic acid, carbon dioxide, and water. Additionally, PLA is FDA-approved for food contact applications, making it ideal for food packaging.

Limitations of PLA

Despite its advantages, PLA has several limitations. It has low thermal resistance, making it unsuitable for applications involving high temperatures. PLA is also relatively brittle and has limited barrier properties, which can affect its performance in certain applications. Furthermore, PLA’s hydrophobic nature can impact its degradation characteristics, depending on the specific conditions it’s exposed to.

Types of PLA and Processing Methods

To fully utilize PLA, it’s essential to comprehend its different types and how they’re processed. PLA can be divided into three main sub-families: PDLLA (poly DL-lactic acid), PLLA (poly(L-lactic acid)), and PDLA (poly(D-lactic acid)). These types have the same chemical makeup but differ in their 3-dimensional molecular structure.

Different Forms of PLA

The three main types of PLA are used in various applications based on their properties. PLLA is the most common form used in consumer applications and 3D printing due to its favorable properties. PDLA and PDLLA, on the other hand, have specific uses in medical and industrial applications where their unique characteristics are beneficial.

How PLA is Processed

PLA can be processed using several methods, including 3D printing, casting, injection molding, extrusion, machining, and solvent welding. In 3D printing, PLA is widely used as filament with diameters of 1.75 or 2.85 mm. The processing parameters, such as temperature and cooling rate, can be manipulated to enhance PLA’s performance characteristics for specific applications.

Applications of PLA Plastic

PLA plastic is versatile, finding applications in various industries. Its unique properties make it suitable for a wide range of uses, from consumer goods to medical devices and 3D printing.

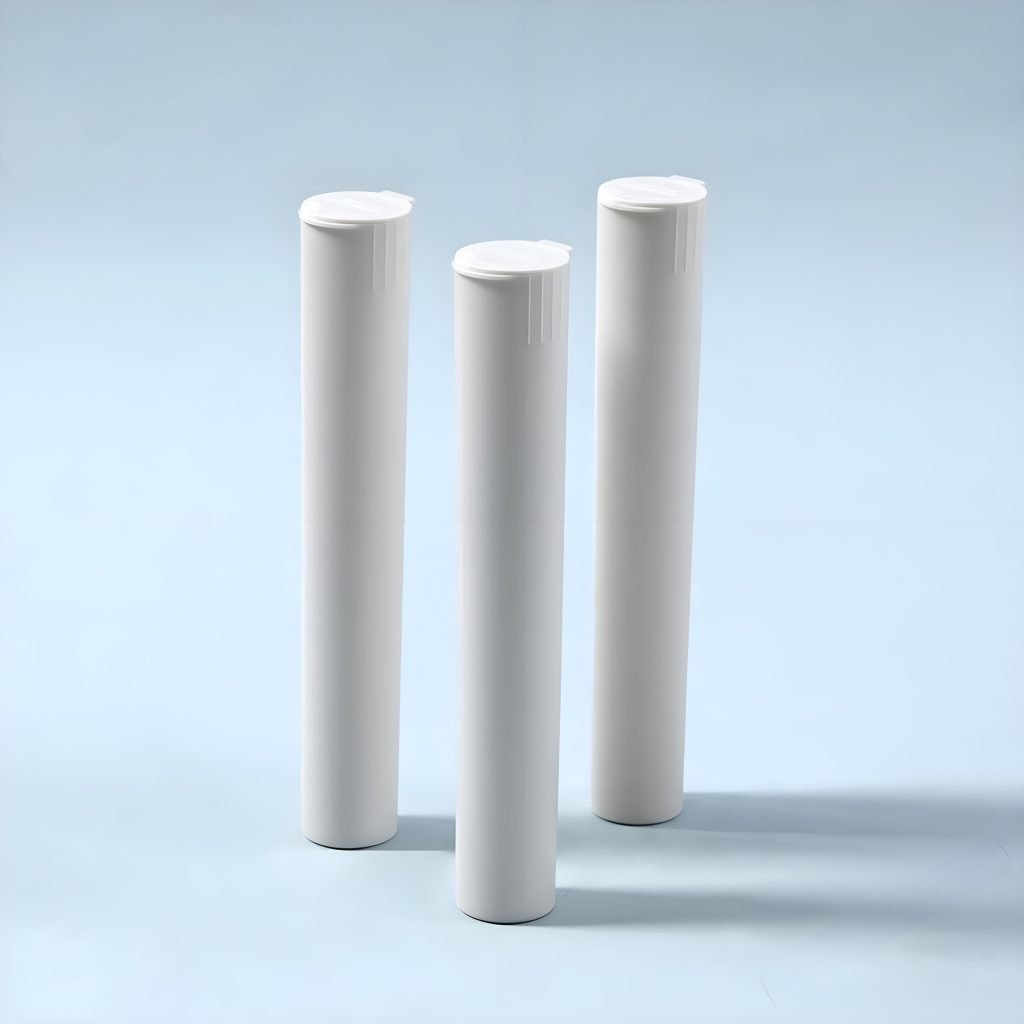

Consumer and Industrial Uses

You can find PLA used in various consumer products, including disposable tableware, food packaging, and compost bags. Major companies are adopting PLA packaging to reduce their environmental footprint.

Medical Applications

PLA is used in the medical field for bioabsorbable sutures, implants, drug delivery systems, and tissue engineering scaffolds. These applications benefit from PLA’s biodegradability and biocompatibility.

3D Printing with PLA

In 3D printing, PLA is a popular filament choice due to its ease of use, minimal warping, and fine detail capabilities. It’s ideal for hobbyists and professionals alike.

Biodegradability and Environmental Impact

PLA plastic’s potential to reduce plastic waste hinges on its biodegradability and the conditions required for it to break down. You should understand that PLA is generally considered compostable in industrial composting conditions, but not in home compost. The degradation process involves three mechanisms: hydrolysis, thermal decomposition, and photodegradation.

For PLA to biodegrade effectively, it requires temperatures above 60°C and high humidity, typically found in industrial composting facilities. This specificity in conditions often leads to misconceptions about PLA’s environmental benefits, as it won’t break down in home compost bins, oceans, or landfills under normal conditions.

The end-of-life options for PLA products include industrial composting, chemical recycling, and incorporation into existing recycling streams, though challenges exist. Emerging technologies in PLA recycling can convert used PLA back into its building blocks, potentially creating a closed-loop system.

FAQ

What is polylactic acid made from?

Polylactic acid is made from renewable resources such as corn starch, sugarcane, or potato starch, which are fermented to produce lactic acid, the building blocks of this bioplastic.

Is polylactic acid biodegradable?

Yes, under controlled composting conditions, polylactic acid can biodegrade, reducing its environmental impact compared to traditional petroleum-based plastics.

Is polylactic acid suitable for 3D printing?

Yes, polylactic acid is a popular filament for 3D printing due to its ease of use, low warping, and minimal odor emission during printing.

How does the production process of polylactic acid impact its properties?

The production process, including the polymerization method and conditions, can significantly affect the physical and mechanical properties of the final product.

What are the limitations of using polylactic acid?

Limitations include its relatively low impact strength, sensitivity to moisture, and limited thermal stability, which can restrict its use in certain applications.