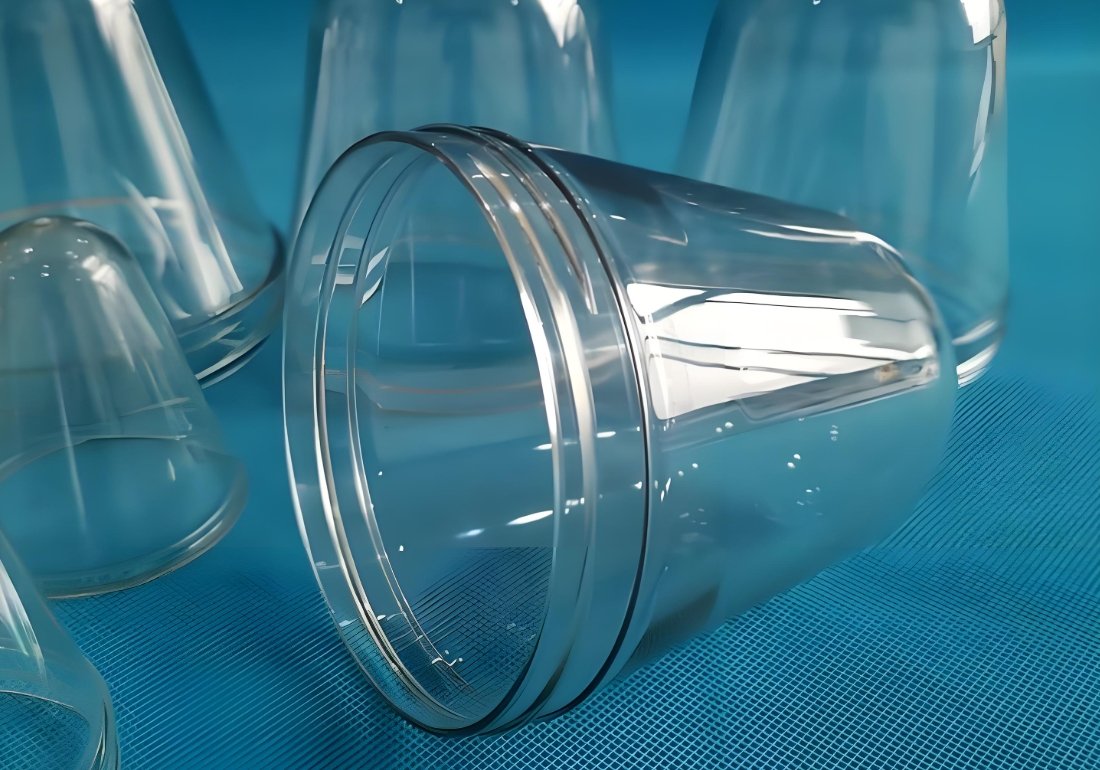

Custom PET Injection Molding Services

Polyethylene Terephthalate (PET) injection molding combines precision engineering with versatile material properties to create durable, lightweight plastic components.

Our team of experienced engineers specializes in PET injection molding for a wide range of applications. With state-of-the-art equipment and comprehensive material expertise, we deliver high-quality PET components that meet your exact specifications.

Durable

Transparent

Recyclable

Standard PET

The most common form of polyethylene terephthalate used in injection molding. Features excellent clarity, good mechanical strength, and moderate chemical resistance. Ideal for general-purpose applications requiring transparency.

PETG

Glycol-modified PET offering enhanced impact resistance, improved processability, and reduced crystallinity. PETG maintains excellent clarity while providing better toughness and easier processing than standard PET.

Reinforced PET

PET formulations with glass fiber or other reinforcements for significantly improved mechanical properties. These grades offer higher strength, stiffness, and dimensional stability for engineering applications.

Key Types and Characteristics of PET Plastic

PET (Polyethylene Terephthalate) is a versatile thermoplastic known for its strength, clarity, and chemical resistance. It comes mainly in amorphous PET (A-PET) for transparency and crystalline PET (C-PET) for heat resistance, making it ideal for packaging, containers, and industrial components.

Specialty PET Formulations

rPET

Recycled polyethylene terephthalate offering sustainable manufacturing options

PET-P

Modified PET with enhanced impact resistance for demanding applications

Crystalline PET

Formulated for enhanced thermal stability and mechanical properties

FDA-Compliant PET

Specially formulated for food contact applications

UV-Stabilized PET

Enhanced resistance to degradation from ultraviolet exposure

Mechanical and Thermal Properties of PET Material

| Property | Value | Unit |

| Density | 1.38-1.41 | g/cm³ |

| Tensile Strength | 50-60 | MPa |

| Flexural Modulus | 2.5-3.0 | GPa |

| Elongation at Break | 120-200 | % |

| Heat Deflection Temperature | 70-80 | °C |

| Melting Point | 245-265 | °C |

| Mold Shrinkage | 0.2-0.6 | % |

Advantages of PET

Excellent clarity and transparency

High tensile strength (50-60 MPa)

Good chemical resistance to many solvents

FDA-approved for food contact applications

100% recyclable (resin identification code #1)

Excellent gas barrier properties

Good dimensional stability

Limitations of PET

Moisture sensitivity during processing

Requires thorough pre-drying (≤0.005% moisture)

processing

Limited heat resistance (HDT ~70°C)

processing

Susceptible to UV degradation without stabilizers

processing

Moderate impact resistance (unmodified grades)

processing

Crystallization can affect transparency

processing

Higher processing temperatures than many plastics

Need Expert PET Injection Molding Services?

Our team specializes in high-precision PET injection molding with industry-leading quality control standards.

Injection Molding Capability in PET Materials

PET injection molding requires specialized expertise to achieve optimal results. The process begins with properly dried PET resin that's precisely heated to its melting point before being injected into custom-designed molds under carefully controlled pressure and temperature conditions.

Key Capabilities

- Multi-cavity mold designs for high-volume production

- Hot runner systems for gate-free parts

- Precision cooling channels for optimal crystallization

- Advanced process monitoring and quality control

- ISO 9001-certified manufacturing processes

- Capability to process virgin and recycled PET

Technical Specifications and Tolerances

| Specification | Standard Tolerance | Precision Tolerance | Notes |

| Dimensional Accuracy | ±0.125 mm | ±0.05 mm | Dependent on part geometry and size |

| Wall Thickness | ±0.1 mm | ±0.05 mm | Minimum recommended: 0.5 mm |

| Draft Angle | 1° – 2° | 0.5° – 1° | Required for proper ejection |

| Surface Finish | SPI-C1 to D3 | SPI-A1 to B2 | Highly polishable for optical clarity |

| Gate Vestige | 0.05 – 0.1 mm | ≤0.025 mm | Hot runner systems minimize gate marks |

Advantages and Disadvantages of PET Injection Molding

Manufacturing Benefits

- Cost-effective for high-volume production

- Excellent dimensional stability for precision parts

- Good flow characteristics with proper processing

- Compatible with existing injection molding equipment

- Ability to create complex geometries

Processing Challenges

- Requires thorough pre-drying (4-6 hours at 160-180°C)

- Narrow processing window compared to other plastics

- Higher processing temperatures (270-290°C)

- Crystallization management for transparent parts

- Special equipment for high-temperature processing

Overcome PET Processing Challenges

Our technical team specializes in optimizing PET injection molding processes to achieve superior results even with challenging applications.

Key Considerations for PET Injection Molding

Design Considerations

✅Wall Thickness: Maintain uniform wall thickness (ideally 0.5-3.0 mm) to prevent warping and sink marks

✅ Draft Angles: Minimum 1° per side, preferably 1.5-2° for easier ejection

✅ Gate Design: Pin gates or hot runner systems preferred for cosmetic parts

✅ Radii and Fillets: Minimum 0.5 mm radius on all corners to reduce stress concentration

✅ Ribs and Bosses: Base thickness should be 60% of adjoining wall to prevent sink marks

✅ Texture: Allow additional draft for textured surfaces (1° per 0.025 mm depth)

Material Preparation

✅ Drying Requirements: PET must be dried to moisture content below 0.005% (50 ppm) to prevent hydrolysis

✅ Drying Parameters: 4-6 hours at 160-180°C in a dehumidifying dryer

✅ Material Handling: Dried material should be processed within 1 hour or kept in sealed, dry containers

Processing Parameters

✅ Melt Temperature: 270-290°C (optimum around 280°C)

✅ Mold Temperature: 15-40°C for amorphous parts, 80-120°C for crystalline parts

✅ Injection Speed: Moderate to fast to prevent premature freezing

✅ Cooling Time: Sufficient to ensure dimensional stability (varies by wall thickness)

PET Injection Molding Applications

Industries We Serve

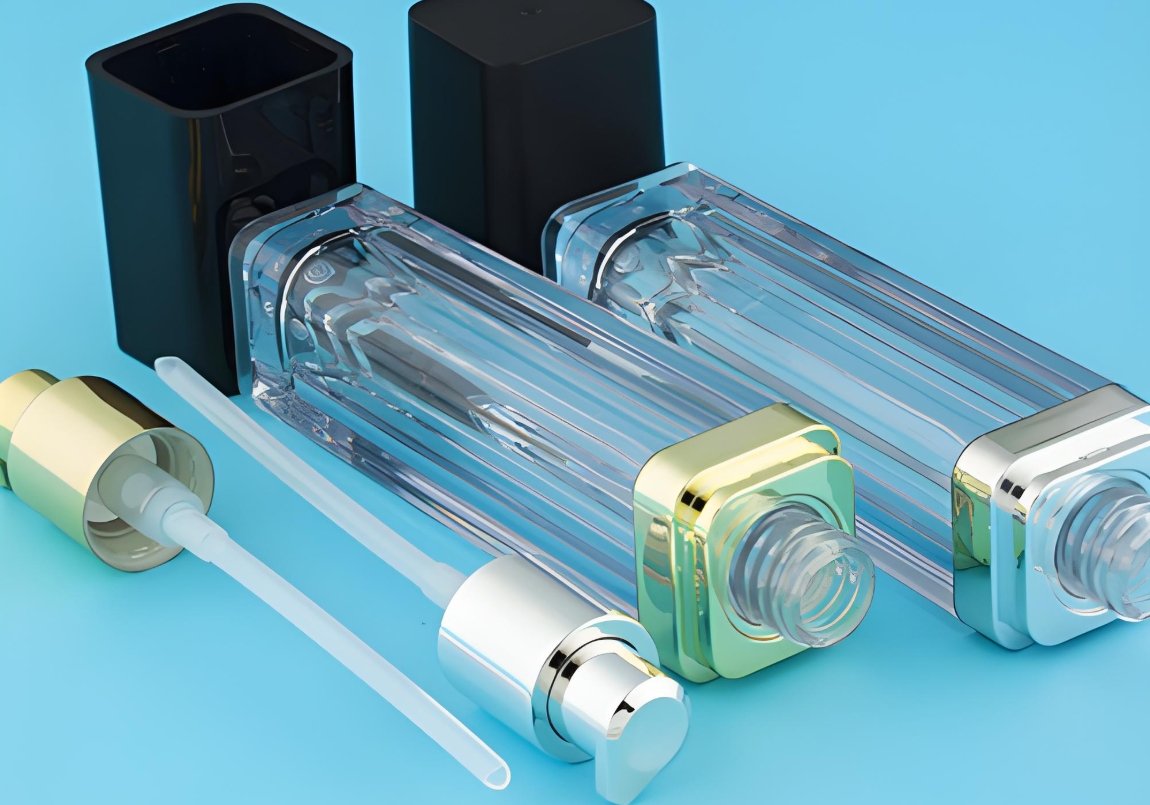

PET injection molding is widely used to produce strong, lightweight, and transparent parts. Common applications include packaging, medical, and precision components in consumer and industrial products.

Consumer & Industrial

Automotive interior components

Electrical insulators

Household appliance parts

Precision mechanical components

Medical Applications

Medical device components

Pharmaceutical containers

Diagnostic equipment housings

Sterilizable medical tools

Packaging Industry

Food packaging and trays

Cosmetic and personal care containers

Pharmaceutical packaging

Clamshell containers

PET Injection Molding FAQs

PET offers several environmental advantages. It's 100% recyclable (resin identification code #1) and widely accepted in recycling programs globally. It has a lower carbon footprint compared to glass or metal alternatives due to its lightweight nature, reducing transportation emissions. Additionally, recycled PET (rPET) can be used in many applications, creating a circular economy opportunity while maintaining material properties.

PET can achieve a wide range of surface finishes, from high-gloss to matte textures. It's highly polishable, allowing for optical-quality surfaces (SPI-A1) when required. Textured surfaces can be created through mold texturing techniques. For transparent applications, proper mold temperature control and processing parameters are essential to prevent crystallization that could affect clarity.

Need to discuss PET injection molding project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Need Immediate Assistance?

Our technical team is ready to discuss your PET injection molding requirements.