Did you know that over 70% of products require some form of marking or decoration during manufacturing? For complex or irregularly shaped items, traditional printing methods often fall short. This is where pad printing comes into play, offering a versatile solution for decorating 3D objects with precision.

This guide will walk you through the process of pad printing, explaining how it works, the materials it can be used on, and the benefits it offers for product decoration and marking, ensuring you understand if this technology is right for your manufacturing needs.

Overview of Pad Printing

In the realm of manufacturing, pad printing stands out for its versatility. You are likely to encounter products with intricate designs printed on irregular shapes, and that’s where pad printing plays a crucial role. Pad printing, also known as tampo printing or tampography, is a specialized indirect offset printing process that uses a silicone pad to transfer ink from an etched plate onto three-dimensional objects.

What Is Pad Printing (Tampo Printing)

Pad printing is unique because of its ability to conform to irregular surfaces. The flexible silicone pad can compress and expand to wrap around curves, recesses, and textured areas that would be impossible to print with traditional methods. This makes it an ideal printing technique for a wide range of products.

Why Pad Printing Is Popular in Manufacturing

Pad printing has become popular across numerous industries due to its precision, versatility, and ability to print on virtually any material, including plastics, metals, glass, ceramics, and even medical devices. Unlike other printing methods, pad printing can decorate products after they’ve been fully assembled, allowing for greater manufacturing flexibility and reducing production complexity.

The Science Behind Pad Printing Technology

The science behind pad printing is rooted in the unique properties of silicone pads and specially formulated inks. You might wonder how this technology enables the transfer of images onto various surfaces with such precision.

Basic Principles

Pad printing operates on the principle of indirect offset printing. The process begins with an etched plate, known as a cliché, where the image is recessed below the surface and filled with ink. The depth of this etching directly affects the opacity and quality of the final print.

Indirect Offset Printing Process

When the silicone pad compresses onto the plate, it creates a momentary vacuum effect that causes the ink to adhere to the pad rather than remain in the plate’s recessed areas. This step is crucial for the image transfer process.

Image Transfer Mechanics

As the ink on the pad’s surface is exposed to air, it becomes tacky, which is crucial for the transfer process. This tackiness allows the ink to release from the pad and adhere to the substrate during the printing phase. The silicone pad’s elastomeric properties enable it to deform and conform to irregular surfaces while maintaining the integrity of the image being transferred.

The entire pad printing process relies on precise timing and controlled environmental conditions, as factors like temperature and humidity can significantly impact ink transfer efficiency and print quality. By understanding these principles, you can appreciate the complexity and versatility of pad printing technology.

Essential Components of a Pad Printing System

The success of pad printing lies in its four essential components, which work in harmony to deliver precise prints.

Printing Pads: Types, Materials, and Shapes

Printing pads are three-dimensional objects typically molded from silicone rubber. They vary in shape and diameter depending on the application. The shape of the pad is critical to print quality – round pads are versatile for general applications, while bar pads are ideal for long, narrow images. Custom-shaped pads can be designed for specific challenging applications.

Printing Plates (Clichés): Materials and Preparation

Printing plates, also known as clichés, are used to contain the desired artwork etched into their surface. They come in different materials, including photopolymer for short runs, thin steel for medium runs, and thick steel for long production runs. The choice of plate material directly impacts image quality and production longevity.

Ink Cups and Ink Systems

Ink cup systems have evolved from open inkwell designs to sealed ink cup systems, offering better ink management, reduced evaporation, and cleaner operation. These systems combine the ink reservoir, flood bar, and doctor blade functions into one component, enhancing the overall efficiency of the pad printing process.

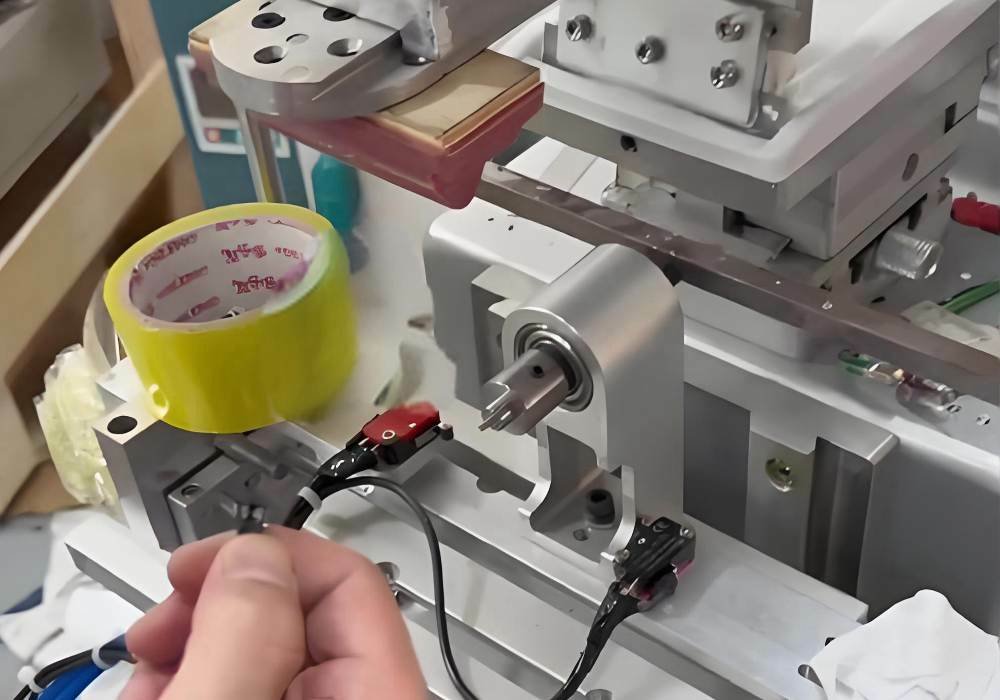

Pad Printing Machines

Modern pad printing machines range from simple manual units to fully automated multi-color systems with integrated part handling. Options for rotary tables, linear conveyors, or custom fixtures are available to optimize production efficiency. The choice of machine depends on the specific requirements of your printing project.

The Complete Pad Printing Process Explained

The pad printing process involves a series of precise steps that enable the transfer of intricate designs onto different materials. You will gain a deeper understanding of how this technology works by exploring the mechanics behind the printing cycle.

Step-by-Step Printing Cycle

The complete pad printing process follows a precise cycle that begins with the ink cup in the “home position” covering the etched artwork area on the printing plate. As the sealed ink cup moves away from the etched area, it removes excess ink, leaving ink only in the recessed image areas. At this point, the exposed ink begins to become tacky as solvents evaporate.

The silicone pad then descends onto the plate, compressing against it and picking up the tacky ink from the etched image through a combination of air pressure and the ink’s adhesive properties. As the pad lifts away from the plate, it carries the ink in the exact shape of the etched image.

The pad then moves to the substrate and compresses against it, transferring the ink from the pad to the product surface with remarkable precision, even conforming to irregular shapes.

Open Inkwell vs. Sealed Ink Cup Systems

Modern sealed ink cup systems offer significant advantages over older open inkwell systems, including reduced solvent evaporation, consistent ink viscosity, and cleaner operation with less maintenance. You can benefit from these advancements by choosing the right system for your printing needs.

Single-Color vs. Multi-Color Printing

For multi-color printing, the process can be configured either with multiple printing stations in sequence or with a single station that completes each color before moving to the next. Precise registration is critical for achieving high-quality results.

What Materials Can Be Pad Printed

Pad printing stands out for its capability to print on virtually any material, offering manufacturers a flexible decoration solution. This versatility is one of the key reasons pad printing is widely used across various industries.

Compatible Substrates

Pad printing can be applied to a diverse range of materials, including plastics such as ABS, PP, PE, PVC, and polycarbonate. Metals like aluminum, stainless steel, and titanium are also compatible, along with glass, ceramics, rubber, silicone, wood, and coated or painted surfaces. This broad compatibility makes pad printing an ideal choice for decorating items with complex geometries or curved surfaces.

Material Preparation Requirements

To ensure optimal ink adhesion, many materials require specific preparation before printing. This may involve cleaning with solvents to remove contaminants, flame or corona treatment to increase surface energy, or applying primers for challenging surfaces. Proper preparation is crucial for achieving high-quality, durable prints.

Challenging Materials and Solutions

Certain materials present specific challenges. For instance, polyolefins like PE and PP typically require pre-treatment due to their low surface energy. Silicone demands specialized inks, while textured surfaces may necessitate modified pad shapes or ink formulations. Testing is crucial when working with new materials to determine the appropriate ink system and pre-treatment methods.

Main Advantages of Pad Printing

Versatility in Printing on Various Shapes

Pad printing offers unmatched versatility in its ability to print on virtually any shape – from flat surfaces to complex curves, recessed areas, and textured surfaces. The silicone pad’s ability to conform to irregular surfaces eliminates the need for specialized fixtures or complex product orientation systems, simplifying the manufacturing process and reducing associated costs.

Precision and Image Quality

The precision of pad printing is remarkable, allowing for fine details, small text (down to 1-2 point font), and intricate graphics to be reproduced with exceptional clarity, even on tiny components or medical devices. This level of precision is critical for industries where detail is paramount.

Durability of Printed Images

Images created through pad printing demonstrate excellent durability, with proper ink selection resulting in prints that resist abrasion, chemicals, UV exposure, and washing. This is particularly important for products that face demanding environments, ensuring that the printed images remain intact over time.

Cost-Effectiveness for Production Runs

From a production standpoint, pad printing offers excellent cost-effectiveness for both short and long runs, with quick setup times, minimal waste, and the ability to print multiple colors in a single production cycle. Pad printing equipment can be easily integrated into existing production lines, ranging from simple manual systems to fully automated multi-color machines that synchronize with your manufacturing workflow.

In summary, pad printing’s versatility, precision, durability, and cost-effectiveness make it a highly advantageous printing technique for various manufacturing needs.

Limitations and Challenges of Pad Printing

Understanding the limitations of pad printing is crucial for determining its feasibility for your manufacturing needs. While pad printing offers versatility and precision, it is not without its challenges.

Size and Coverage Constraints

One of the primary limitations of pad printing is its size constraint. Standard pad printing is typically limited to image areas of approximately 6 inches in diameter. Although specialized equipment can accommodate larger images, this comes at an increased cost. Additionally, coverage can be challenging for large solid areas, as pad printing works best with line art, text, and graphics.

Color Limitations

Color reproduction in pad printing has its limitations compared to digital printing. While multi-color pad printing is possible, each color requires a separate plate and printing cycle. This makes complex full-color images with smooth gradients more challenging to reproduce.

Environmental Considerations

Environmental factors significantly impact the pad printing process. Temperature and humidity must be carefully controlled to ensure consistent ink viscosity, proper drying, and optimal transfer from pad to substrate. Climatic conditions can affect the performance of pad printing ink, especially in open ink well style printers.

Most traditional pad printing inks contain volatile organic compounds (VOCs), though the industry has been developing more environmentally friendly alternatives like UV-curable and water-based systems.

Common Applications of Pad Printed Parts

Pad printing’s unique capabilities have made it an essential method for printing on complex shapes and surfaces. This technique is widely used across various industries due to its precision, durability, and versatility.

Medical and Pharmaceutical Industry

In the medical and pharmaceutical industry, pad printing is used for printing on medical devices such as syringes, surgical instruments, and implantable items like catheter tubes and contact lenses. It is also used for marking pills and printing on equipment control panels. The precision and durability of pad printing are critical in these applications.

Automotive Components

Automotive manufacturers rely on pad printing for dashboard controls, switch symbols, interior trim components, and exterior emblems. These parts must withstand years of use and exposure to harsh conditions, making pad printing’s durability essential.

Consumer Electronics and Appliances

Consumer electronics and appliances benefit from pad printed control panels, button symbols, brand logos, and operating instructions. These prints resist wear from frequent touching and cleaning, ensuring that the products remain functional and visually appealing.

Advanced Pad Printing Techniques

Advanced pad printing techniques have revolutionized the manufacturing industry by enabling complex decorations and functional applications beyond simple graphic reproduction. These advancements have expanded the capabilities of pad printing, making it a versatile process for various industries.

Multi-Color Registration

Multi-color registration techniques have evolved to achieve precise alignment between colors, utilizing specialized fixtures and optical registration systems. Advanced pad printing machines maintain tight tolerances across multiple print cycles, ensuring high-quality prints.

Specialty Inks and Effects

The use of specialty inks has dramatically expanded pad printing applications. Conductive inks for printed electronics, thermochromic inks that change color with temperature, and photoluminescent inks that glow in darkness are just a few examples. These inks enable the creation of functional and decorative elements that were previously impossible to achieve.

Automation and High-Volume Production

Modern pad printing machines incorporate automation features such as programmable pad stroke adjustments and vision inspection systems. Integration with robotic part handling systems has enabled fully automated pad printing cells, significantly increasing throughput and consistency in high-volume production environments.

Comparing Pad Printing to Other Printing Methods

Pad printing stands out among other decoration techniques due to its unique ability to transfer 2D images onto 3D objects with precision and durability. As a product decorating process, pad printing, also known as tampon printing, tampo printing, or tamponography, ensures decoration that is both durable and highly repeatable for mass production.

Pad Printing vs. Screen Printing

When compared to screen printing, pad printing excels at decorating curved or irregular surfaces and printing finer details. Screen printing, on the other hand, is typically more efficient for large flat areas, longer runs, and applications requiring thick ink deposits.

Pad Printing vs. Digital Printing

Digital printing offers advantages in full-color reproduction and variable data printing. However, it cannot match pad printing’s ability to print on three-dimensional objects or its durability on products exposed to handling or harsh environments.

Choosing the Right Printing Method for Your Project

The decision between printing methods should consider factors like product geometry, material composition, production volume, durability requirements, and decorative complexity. Often, pad printing machines offer the best balance for products with irregular shapes requiring precise decoration.

By understanding how pad printing compares to other decoration methods, you can select the most appropriate technology for your specific product requirements, ensuring the best possible outcome for your manufacturing needs.

Conclusion: Is Pad Printing Right for Your Manufacturing Needs?

Pad printing is commonly used in industries that manufacture precision parts or sensitive products, such as medical devices, cosmetic packaging, automotive controls, industrial instruments, and consumer electronics. To determine if pad printing is the idea l choice for your manufacturing requirements, it’s essential to examine its key characteristics.

Several factors can help you decide if pad printing is right for your application. If your products have curved, recessed, or irregular surfaces, pad printing is likely an ideal solution. It’s also suitable when you need to print on assembled components rather than flat materials, or when precise, high-resolution graphics or text are required.

Pad printing excels when durability is essential, offering exceptional wear resistance. It provides versatility across both low and high-volume manufacturing scenarios, with quick changeover capabilities that make it cost-effective even for shorter production runs. Working with an experienced pad printing partner can ensure optimal adhesion and print quality by conducting material compatibility tests and recommending the most suitable ink and pre-treatment process.

By evaluating these factors and considering the unique benefits of pad printing, you can make an informed decision about whether this printing method is right for your manufacturing needs.