Did you know that nearly 80% of the world’s manufactured goods involve some form of metal finishing? Among these, nickel plating stands out as a crucial process, enhancing both the functionality and aesthetics of metal components.

Understanding the different types of nickel plating and their applications is essential for enhancing metal components’ performance and longevity.

What Is Nickel Plating?

Nickel plating is a process that deposits a thin layer of nickel onto a metal substrate, creating a surface with enhanced properties compared to the base material. This is achieved by immersing the object to be plated into an electrolyte solution containing dissolved nickel and then applying an electrical current to facilitate the deposition of nickel ions onto the substrate’s surface. The result is a layer that provides improved corrosion resistance, wear resistance, and aesthetic appeal.

The Science Behind Nickel Plating

Understanding the science behind nickel plating requires a look into the fundamental principles of electroplating.

Basic Electroplating Principles

The science of nickel plating relies on fundamental electrochemical principles where an electrical current drives the deposition of nickel ions from a solution onto a conductive substrate. In the electroplating setup, the object to be plated serves as the cathode (negative electrode), while pure nickel functions as the anode (positive electrode), both immersed in an electrolyte solution containing dissolved nickel salts.

The efficiency of the nickel anode dissolution approaches 100% under optimal conditions. However, the cathode efficiency typically ranges between 90-97%, creating a slight imbalance that gradually increases the nickel concentration and pH of the solution over time.

The Electrochemical Process

When current flows through the system, nickel atoms at the anode oxidize to form nickel ions (Ni²⁺) that dissolve into the electrolyte solution. At the cathode, these ions accept electrons and reduce back to metallic nickel, forming a coating on the substrate. Various factors including current density, temperature, pH, and solution composition must be carefully controlled to achieve the desired nickel deposit characteristics such as thickness, brightness, hardness, and internal stress.

Types of Nickel Plating Solutions

Nickel plating solutions come in different formulations, each with its unique characteristics.

Watts Nickel Baths

The Watts nickel bath, developed by Oliver Patterson Watts in 1916, remains one of the most widely used formulations. It typically contains nickel sulfate, nickel chloride, and boric acid, making it capable of producing both bright decorative finishes and semi-bright functional coatings. You can achieve bright nickel deposits for decorative purposes and corrosion protection, as well as semi-bright deposits for engineering applications where high corrosion resistance and ductility are required.

Nickel Sulfamate Solutions

Nickel sulfamate solutions are preferred for engineering applications that require low internal stress, high deposition rates, and excellent ductility. These characteristics make them ideal for electroforming and applications that require thick deposits. You can benefit from the high efficiency and corrosion protection offered by nickel sulfamate solutions.

All-Chloride and Sulfate-Chloride Baths

All-chloride baths operate at lower voltages and allow for thick nickel deposits, although they typically produce coatings with higher internal stresses. Sulfate-chloride solutions, on the other hand, offer a middle ground between Watts and all-chloride baths, providing higher deposition rates than Watts baths while maintaining lower internal stresses. You can choose between these solutions based on your specific requirements for deposit thickness and stress tolerance.

Specialty Nickel Plating Solutions

Specialty solutions include hard nickel baths for applications requiring exceptional hardness and wear resistance, black nickel for decorative dark finishes, and boric acid-free formulations that address environmental and regulatory concerns. You can select from these specialty solutions to meet specific needs, such as enhanced wear resistance or compliance with environmental regulations.

Materials Compatible with Nickel Plating

Nickel plating is a versatile process that can be applied to various metals, but the compatibility of the base metal with nickel is crucial for a successful outcome.

Common Base Metals for Plating

Most common metals, including steel, copper, brass, and zinc alloys, readily accept nickel plating, making them ideal base materials for both decorative and functional applications. These metals are widely used in various industries due to their compatibility with nickel, allowing for a strong bond between the base metal and the nickel coating.

Challenging Materials and Solutions

Some materials, such as stainless steel and aluminum, present challenges for direct nickel plating. Stainless steel’s passive oxide layer requires a copper strike or other intermediate layer to achieve proper adhesion. Aluminum and its alloys are notoriously difficult to plate directly with nickel due to their reactive nature and natural oxide layer, often requiring specialized zincate treatments or other preparatory processes.

The concept of “dissimilar metals” is crucial in nickel plating, as the compatibility between the base metal and nickel affects adhesion quality and potential galvanic corrosion issues. For challenging materials, a strategic approach often involves applying intermediate layers, such as copper or nickel strike, that are more compatible with both the base metal and the final nickel coating.

Surface Preparation and Post-Plating Treatments

The quality of the nickel plating process is significantly influenced by how well the surface is prepared before plating and how the part is treated after plating.

Cleaning and Pre-Treatment Steps

Proper surface preparation is arguably the most critical step in achieving high-quality nickel plating results. Even microscopic contaminants can cause adhesion failures and surface defects. The cleaning process typically involves a sequence of steps, including degreasing to remove oils, alkaline cleaning to remove general soils, acid pickling to remove oxides, and electrocleaning to remove final traces of contaminants. For complex parts, additional preparation steps may include masking areas that should not be plated, mechanical finishing to achieve the desired surface texture, and specialized treatments for difficult materials.

Post-Plating Finishing Processes

After plating, parts often undergo post-treatment processes such as heat treatment to relieve internal stresses, chromate conversion coatings for additional corrosion protection, or sealing treatments to enhance performance. Quality control inspections after both preparation and post-plating steps are essential to make sure the finished parts meet specifications for adhesion, thickness, appearance, and functional properties. By carefully controlling these steps, you can achieve the desired results and ensure the longevity of the plated part, even when exposed to water or other environmental factors.

Using water rinses between steps and maintaining a clean environment during the plating process can further enhance the quality of the final product. Ensuring that each step is carefully executed will result in a superior nickel plating finish.

Benefits of Nickel Plating

With its unique combination of properties, nickel plating provides a versatile solution for a wide range of applications. You can leverage these benefits to enhance the performance, durability, and appearance of your components.

Corrosion and Wear Resistance

Nickel plating provides exceptional corrosion resistance by creating a protective layer that shields the base metal from environmental exposure. This significantly extends the service life of components in harsh conditions. The wear resistance properties of nickel coatings also make them ideal for high-friction applications, with hardness values that can be tailored through plating parameters.

Aesthetic Advantages

From an aesthetic perspective, nickel plating offers a range of finish options, from high-luster bright nickel to satin or matte finishes. This allows for versatility in design applications, making it a popular choice in the automotive industry for bumpers, rims, and trim. You can achieve a bright gleam with a light polish, maintaining the appearance of your end product.

Functional Properties

The functional properties of nickel coatings extend beyond protection to include enhanced electrical conductivity, magnetic properties, solderability, and thermal characteristics. Unlike many other metal finishes, nickel plating results in a stable surface that doesn’t oxidize at room temperature, maintaining its appearance and functional properties over extended periods.

Applications of Nickel Plating

You can find nickel plating applied in numerous fields, from decorative items to industrial components. Nickel plating’s versatility stems from its ability to provide both aesthetic appeal and functional benefits, making it a valuable process across various industries.

Decorative Applications

Nichel plating is widely used in decorative applications, including consumer products, automotive trim, household fixtures, and fashion accessories. Its bright, lustrous finish enhances visual appeal while providing corrosion protection. The use of nickel plating in these areas not only adds to the product’s appearance but also extends its lifespan.

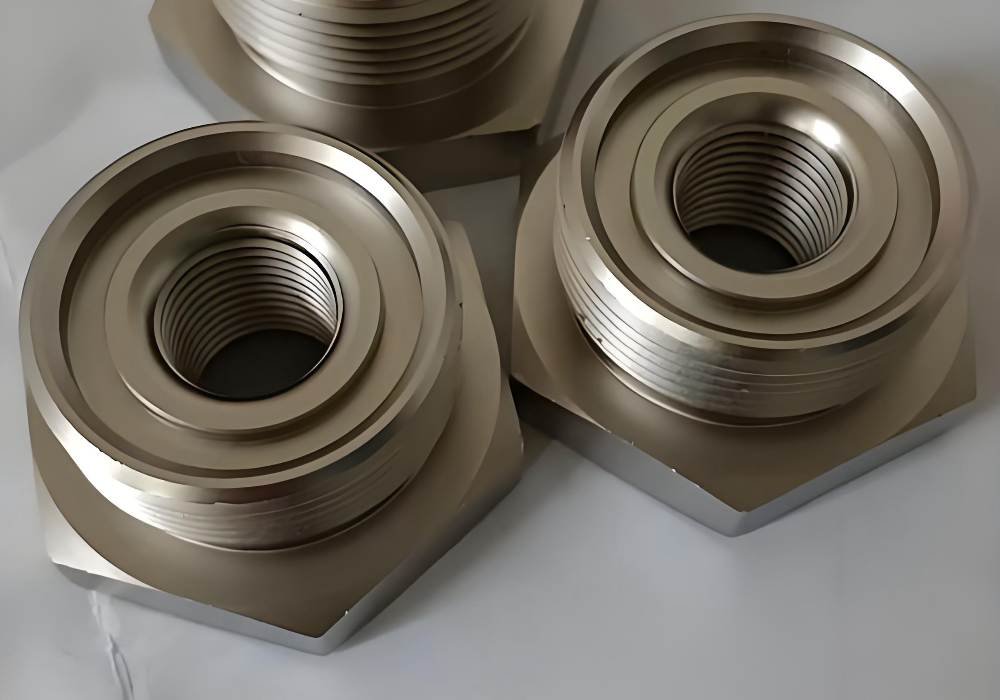

Engineering and Industrial Uses

In engineering and industrial contexts, nickel plating is valued for its wear resistance and dimensional stability. It is ideal for precision components in aerospace, automotive, and manufacturing equipment. Nickel plating provides a durable finish that withstands the rigors of industrial use, improving the longevity of parts.

Electroforming Applications

Nickel electroforming is a specialized application where thick nickel deposits are built up on a mandrel and then removed to create complex, standalone nickel components. These components are used in various applications, including molds, dies, and musical instrument parts, showcasing the versatility of nickel plating in producing intricate parts with high precision.

Conclusion

The significance of nickel plating in modern manufacturing cannot be overstated. As a versatile metal finishing process, it offers a unique combination of decorative appeal and functional performance. You can choose from various nickel plating solutions to suit your specific application needs.

Investing in proper surface preparation and process control extends product life, enhances performance, and improves aesthetic appeal. As environmental regulations evolve, innovations in nickel plating technology demonstrate the industry’s commitment to sustainability while maintaining exceptional performance across diverse industries and applications.