Did you know that nearly 70% of product failures in precision engineering are due to improper hole dimensions and length specifications? Mastering the technique of creating precise holes is crucial for ensuring the quality and functionality of your product.

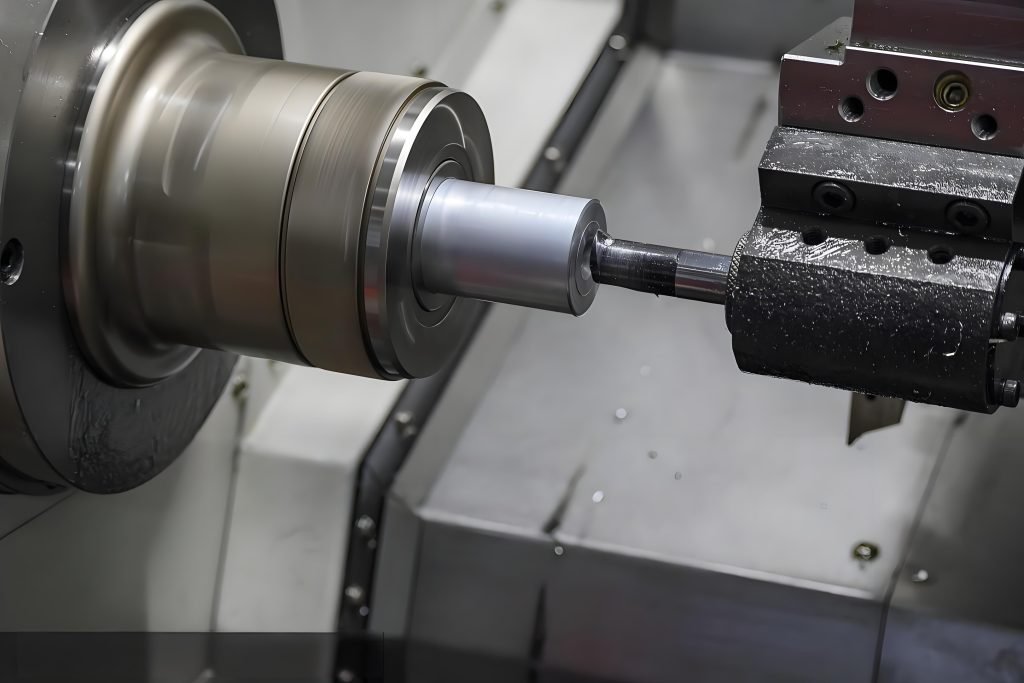

Counterboring is a critical machining process that creates a flat-bottomed hole to accommodate fastener heads, providing both structural integrity and a clean finish. By understanding the fundamentals of counterbore and its application, you can significantly improve the aesthetic appearance and overall performance of your engineering projects.

As you delve into the world of precision engineering, having the right information on counterbore techniques and best practices is essential. This guide will walk you through the critical aspects of counterboring, including tools, techniques, and execution methods to achieve perfect holes every time.

Understanding Counterbore Fundamentals

To master precision engineering, it’s crucial to understand the fundamentals of counterbore. A counterbore is a cylindrical flat-bottomed hole that enlarges another hole, allowing the head of a fastener to sit flush with or below the workpiece surface.

What is a Counterbore?

A counterbore is defined by its cylindrical shape and flat bottom, which distinguishes it from other types of holes. This feature is essential in

Purpose and Applications in Engineering

Counterbores are used in various engineering applications, including mechanical assemblies and furniture manufacturing, where flush mounting is necessary. The correct counterbore diameter is critical to accommodate the specific fastener type.

Difference Between Counterboring and Countersinking

Counterboring creates a cylindrical recess with a flat bottom, whereas countersinking creates a conical recess with angled sides. The choice between these two techniques depends on the specific requirements of your product and the tool you use, which can impact the price and quality of the finished hole.

Counterbore Tools and Equipment

The world of counterbore tools is vast and varied, with different types and materials suited to specific applications.

Types of Counterbore Tools

Counterbore tools come in several types, including fixed-size, adjustable, and interchangeable pilot counterbores, each designed for specific tasks and offering unique benefits.

High-Speed Steel vs. Carbide Options

High-speed steel and carbide counterbore tools differ significantly in durability, cutting performance, and price. Carbide tools, while more expensive, offer superior performance and longevity.

Selecting the Right Tool for Your Application

When selecting a counterbore tool, consider factors such as the material being worked on, the desired finish, and the tool’s compatibility with your machinery.

Counterbore tools can be modified in 2-3 working days to suit specific needs, including adjustments to shank diameters, addition of coolant through, and alterations to pilot diameters.

Creating Perfect Counterbores

Precision counterboring is a multi-step process that requires careful planning and execution. To achieve optimal results, you must understand the intricacies involved in creating counterbores.

Step-by-Step Counterboring Process

You start by drilling the initial hole, followed by setting up the counterbore tool. Proper machine parameters are crucial for accurate counterbore creation. Using the right

Determining Proper Counterbore Sizing

To determine the correct counterbore size, you need to consider the fastener specifications. This involves understanding clearance requirements and standard sizing conventions.

Diameter Considerations

The diameter of the counterbore should be slightly larger than the fastener head. This ensures a proper fit and allows for easy installation.

Depth Calculations

Calculating the correct depth involves considering the overall length of the fastener, material thickness, and desired protrusion or flush mounting requirements. Accurate depth calculation is critical for a successful counterbore.

Common Mistakes and How to Avoid Them

Common counterboring mistakes include incorrect depth, improper speed and feed rates, and tool selection errors. To avoid these, you should carefully plan your counterboring process, selecting the right tool and machine parameters for your specific application. This helps ensure accurate alignment and prevents issues like off-center or misaligned holes.

Conclusion: Optimizing Your Counterbore Applications

To optimize your counterbore applications, it’s essential to understand the fundamentals and best practices. Proper tool selection and technique directly impact the quality and functionality of your final product, ensuring that your tools are used effectively.

Considering the overall length and diameter specifications during the design phase can prevent issues during manufacturing and assembly, as it directly affects the length of the counterbore.

By applying the information presented in this guide, you can maintain your counterbore tools properly, keep commonly used tools in stock to reduce project delays, and potentially reduce price through bulk purchasing, resulting in higher quality products and more efficient manufacturing.

FAQ

The pilot guides the tool into the existing hole, ensuring accurate alignment and preventing damage to the surrounding material.

The shank diameter should match the diameter of the tool holder or drill press. Check your equipment’s specifications to ensure compatibility.

High-speed steel tools are more affordable and suitable for general-purpose applications, while carbide tools offer greater durability and are ideal for high-wear or high-temperature applications.

To achieve accurate sizing, carefully measure the diameter of the hole and the desired counterbore diameter. Consult the product information or manufacturer’s guidelines for sizing recommendations.

The overall length is typically measured from the tip of the pilot to the end of the shank. Check the product information or consult with the manufacturer to confirm the length.