Are you getting the most out of your lathe operations? The right can make all the difference in achieving precision and efficiency.

Selecting the appropriate for your lathe is crucial for successful machining operations. With various types of available, including boring bars and threading , understanding their specific applications is key.

Modern and automation features have significantly improved the capabilities of these essential machining . The material of the , such as , also affects performance and longevity.

By understanding the basics and selection criteria for specific applications, you can optimize your lathe operations for quality and cost-effectiveness.

Understanding Lathe Cutting Tools

Lathe cutting tools are crucial for precision machining, serving as the interface between the lathe machine and the workpiece. These tools are designed to remove material from a rotating workpiece in a controlled manner, creating precise shapes and dimensions.

What Are Cutting Tools in Lathe Machines?

Cutting tools in lathe machines are specialized implements designed to remove material from a rotating workpiece. They determine the quality, accuracy, and efficiency of the machining process. The basic principle involves a stationary cutting tool engaging with a rotating workpiece, with the tool’s geometry and positioning determining the resulting cut.

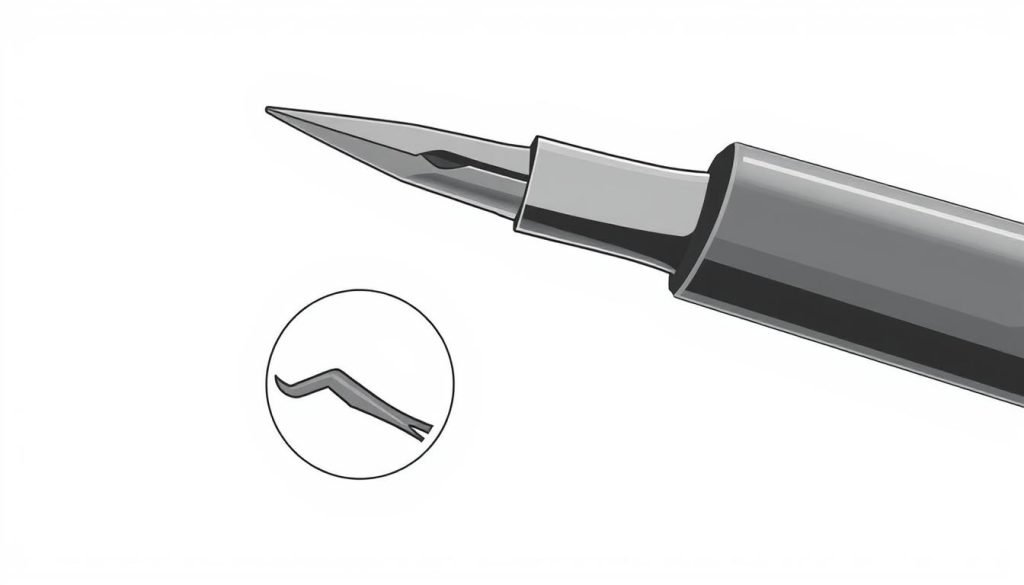

Essential Components of Lathe Cutting Tools

The essential components of lathe cutting tools include the shank, the cutting edge, and in modern tools, replaceable inserts. The shank is the portion held by the tool holder, while the cutting edge engages with the workpiece. Modern lathe tooling systems often feature indexable designs with carbide inserts that can be rotated or replaced when worn.

The geometry of a turning tool, including rake angles, relief angles, and nose radius, plays a crucial role in determining cutting performance, surface finish, and tool longevity. Understanding the relationship between tool geometry, workpiece material, and cutting parameters is essential for optimizing lathe operations.

Types of Lathe Cutting Tools

Understanding the different types of lathe cutting tools is essential for optimizing your machining processes. Lathe cutting tools are designed to perform various operations, including turning, facing, and forming. The right tool can make a significant difference in the quality of your workpiece.

Single-Point Cutting Tools

Single-point cutting tools feature one primary cutting edge and are the most common type used in lathe operations. They are ideal for turning, facing, and forming operations, offering simplicity and versatility.

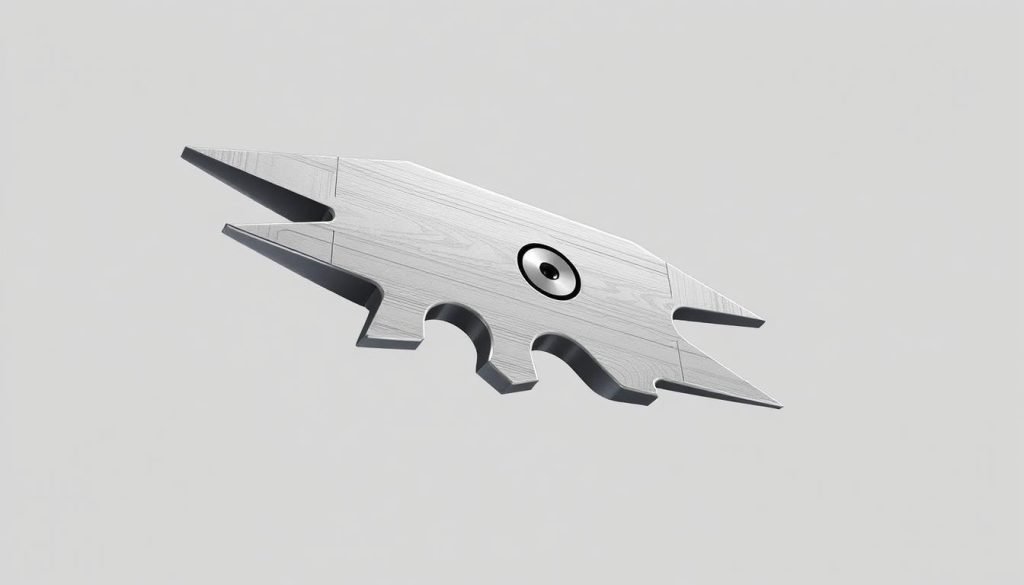

Multi-Point Cutting Tools

Multi-point cutting tools contain multiple cutting edges that engage with the workpiece simultaneously, enabling more complex operations and often higher material removal rates. These tools are perfect for intricate designs and high-volume production.

Specialized Lathe Cutting Tools

Specialized lathe cutting tools are designed for specific operations, including boring, threading, and grooving. These tools are crucial for achieving precise results in complex machining tasks.

Boring Bars and Internal Tools

Boring bars are specialized tools designed for internal machining operations, featuring extended shanks that reach into workpiece cavities. They are perfect for boring, internal turning, and facing operations.

Threading and Grooving Tools

Threading tools create precise thread profiles, while grooving tools feature narrow cutting edges for creating channels and recesses. Both are essential for detailed machining operations.

Parting and Cut-Off Tools

Parting and cut-off tools are designed for separating a completed workpiece from the stock material, minimizing material waste. They are a crucial part of the machining process.

Materials Used in Lathe Cutting Tools

Choosing the right material for your lathe cutting tools is crucial for optimal performance. The material used can significantly impact the tool’s durability, efficiency, and overall machining quality.

High-Speed Steel (HSS) Tools

High-Speed Steel tools are traditional materials used for lathe cutting tools, offering good toughness, ease of resharpening, and relatively low cost. They remain valuable for low-volume production and custom work.

Carbide Insert Tools

Carbide insert tools have revolutionized modern machining with their superior hardness and wear resistance. The modular nature of carbide insert systems allows for quick replacement of worn cutting edges, reducing downtime.

Ceramic and Cermet Tools

Ceramic and cermet tools offer exceptional heat resistance and hardness, making them ideal for high-speed machining of hardened materials. Cermet inserts combine the heat resistance of ceramics with improved toughness.

CBN and Diamond Tools

Cubic Boron Nitride (CBN) and diamond tools represent the pinnacle of cutting tool materials, offering extreme hardness and wear resistance. CBN excels in machining hardened steels, while diamond tools are used for non-ferrous materials.

The selection of tool material significantly impacts machining parameters, with advanced materials generally allowing for higher cutting speeds and extended tool life. By choosing the right material, you can optimize your lathe cutting operations.

Selecting the Right Lathe Cutting Tool

To maximize efficiency and precision in your lathe work, it’s essential to understand how to pick the right cutting tool. Selecting the right lathe cutting tool begins with understanding your specific machining requirements, including workpiece material, desired surface finish, tolerance requirements, and production volume. For high-volume production environments, consider the long-term benefits of your tooling choices, such as tool life and reduced downtime.

When choosing turning tools, consider factors like approach angle, insert shape, and nose radius. For threading and grooving operations, use dedicated tools with precise geometries to achieve superior results. Boring bars require careful consideration of the length-to-diameter ratio to minimize vibration. Tool holders and turret configurations also play a crucial role in tool selection.

When shopping for lathe cutting tools, evaluate not just the initial price but also the cost of replacement inserts and the compatibility with your existing equipment. By considering these factors, you can optimize your lathe operations and achieve better results.

FAQ

What is the difference between a single-point and multi-point cutting tool?

A single-point cutting tool has one cutting edge, typically used for turning, boring, and facing operations, whereas a multi-point cutting tool has multiple cutting edges, often used for operations like milling and drilling.

How do I choose the right carbide insert for my turning operation?

To choose the right carbide insert, consider factors such as the material being machined, the desired surface finish, and the operating conditions, including speed and feed rate.

What are the benefits of using a boring bar with a carbide insert?

Using a boring bar with a carbide insert provides improved accuracy, increased tool life, and enhanced surface finish, making it ideal for precision boring operations.

Can I use a grooving tool for other operations besides grooving?

While grooving tools are designed specifically for grooving operations, some can be used for other applications, such as parting or turning, depending on the tool geometry and insert type.

What is the role of tool holders in lathe operations?

Tool holders play a crucial role in securing the cutting tool in place, providing stability, and allowing for precise control over the cutting operation, which is essential for achieving accurate results.