Have you ever wondered whether a common thermoplastic will meet your needs without hidden risks?

This guide gives you a clear answer so you can decide fast. You’ll learn what abs plastic is, how the material behaves, and where it is widely used. We cover key properties like impact strength, heat limits, electrical insulation, and when formulations matter for food-contact parts.

We also explain safety points from regulators, emissions when 3D printing, and practical steps for using abs plastic safely in machining and production. You’ll get help comparing alternatives and real-world application notes so you can judge fit for purpose.

If you want a quote or DFM support, contact Fecision by email and we’ll help move your design to finished parts with confidence.

What ABS Plastic Is and How It’s Made

Start with the basics: how the polymer’s chemistry creates toughness and reliable parts. Acrylonitrile butadiene styrene is a family of copolymers that balances rigidity, impact resistance, and good surface finish. You’ll find it in many engineered products because it works across many processing methods.

Acrylonitrile butadiene styrene explained: a thermoplastic polymer

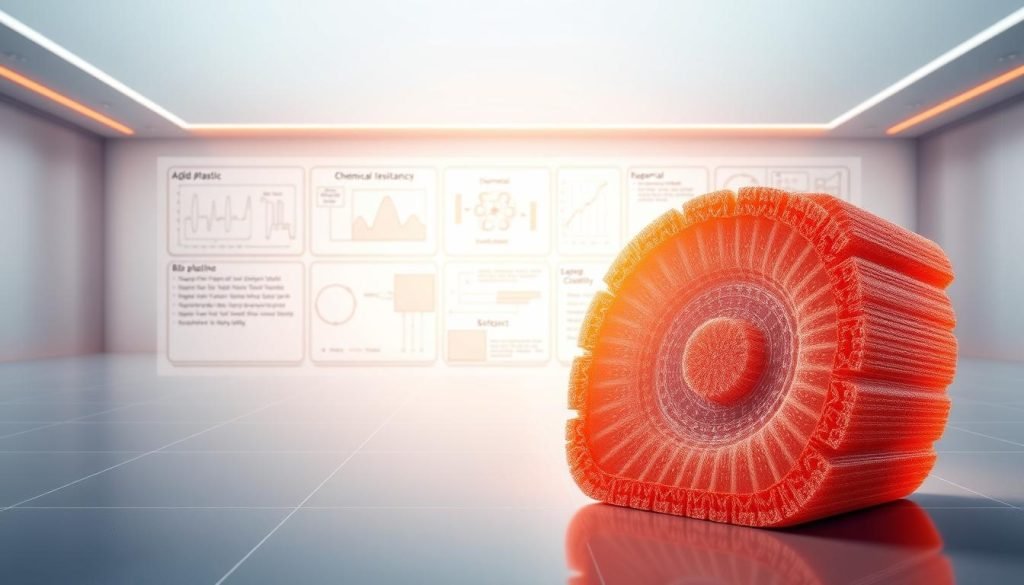

Acrylonitrile contributes chemical resistance and stiffness. Butadiene supplies rubbery toughness. Styrene gives processability and a smooth finish. Together they form a thermoplastic polymer that softens with heat and can be reshaped for molding, machining, or thermoforming.

Polymerization process and why it drives toughness and durability

Polymerization produces long chains and a rubber‑toughened matrix: dispersed butadiene domains sit in a styrene‑acrylonitrile phase. That microstructure is why the material stays tough at low temperatures and resists impact in housings and covers.

Grades vary—platable, flame‑retardant, or heat‑resistant formulations let you match performance and compliance. As a recyclable thermoplastic, this plastic supports regrind when you control quality and processing.

Core Characteristics of ABS Plastic You Need to Know

Performance decisions start with measurable properties—here’s what to check for your design.

Impact, strength, and dimensional stability

Count on a balance of impact and strength that gives rugged parts without excessive weight. Typical tensile ranges sit around 4–8 ksi, while yield values fall near 2.68–7.4 ksi. That mix helps parts resist chipping and retain fit.

Dimensional stability supports tight assemblies and predictable tolerances across normal indoor conditions. Use ribbing and controlled wall thickness to exploit the material’s modulus (0.16–0.421 Mpsi) for added stiffness.

Heat behavior and recommended temperatures

Design for practical heat limits. Max service temperatures commonly range near 143–170°F (61.9–76.9°C). Above those temperatures you risk softening and dimensional change.

Electrical insulation and dielectric behavior

This plastic is a good electrical insulator, making it suitable for housings, covers, and fixtures where dielectric performance matters. Choose grades with consistent processing to keep properties stable across batches.

Chemical, stress, and creep resistance

ABS shows solid resistance to many cleaners and common process fluids. It sustains load over time and performs well in stress and creep tests when you follow recommended wall and rib designs.

Surface finish, color, and specialty grades

Expect reliable surface gloss and wide colorability for decorative parts. Platable, fire‑retardant, and heat‑resistant grades let you match compliance and function. For outdoor use choose UV‑stabilized variants to protect gloss, modulus, and impact strength.

Use these traits to judge if abs plastic fits your engineering needs and to specify the right formulation for your product environment and lifecycle.

Where ABS Excels: Real-World Applications and Parts

Seeing where a material works best helps you match its strengths to your project quickly.

Electronics housings, fixtures, and covers

For consumer electronics, you’ll pick abs plastic for housings and covers that need impact resistance and consistent dimensions.

It also offers electrical insulation that reduces failure modes and keeps devices reliable.

Automotive interiors and protective components

In cars, abs suits dashboards, trims, and protective elements where surface finish and toughness matter.

The balance of stiffness and weight helps meet fit and feel targets for interior parts.

Construction, plumbing, and indoor fittings

Use abs for indoor plumbing parts, panels, and fittings because it resists creep and is easy to fabricate.

Toys, consumer items, and kitchen use

Famous toy bricks like LEGO are made from abs due to precise snap-fit tolerances and lasting color.

For kitchen utensils and food-processing parts, choose only grades formulated and tested for food contact and follow FDA/EFSA guidance.

Prototyping and surface quality

ABS forms cleanly in vacuum forming and prototyping, holding tight radii and detail for low-volume runs.

For indoor or consumer-facing plastic parts, you’ll save time and cost with its consistent surface quality.

Where performance aligns with your product needs, use abs early in DFM to control manufacturability and cost.

Is ABS Safe: What Current Standards and Research Say

Knowing how rules and studies align helps you manage safety and meet compliance for abs plastic. Below is a focused summary of regulatory positions, additive issues, exposure routes, and emissions you should watch.

Food-contact and regulations

FDA and EFSA generally permit properly formulated abs plastic for food contact. Verify your grade’s certification and follow manufacturer conditions and guidelines regulations for processing to keep compliance clear.

Additives and bisphenol notes

Some datasheets may contain bisphenol language. If you have health concerns, specify BPA-free compounds and confirm pigments or stabilizers meet your targets.

Exposure, heat, and long-term use

Contact, high temperatures, and service life change migration risks. Evaluate how users touch parts, how heat is applied, and how long items remain in service to limit exposure.

3D printing emissions and environmental impact

Printing at high temperatures emits ultrafine particles and VOCs; styrene is a key VOC. NIOSH reports elevated UFPs and cell effects. Follow OSHA limits, use enclosures, HEPA plus carbon filtration, and local exhaust to reduce airborne risk.

How to Use ABS Plastic Safely in Your Operation

A few practical steps at the bench or shop will reduce exposure and extend part life.

General handling and shop practices

Store resin dry and away from direct UV to keep materials stable for service. Control shop temperatures and avoid unnecessary preheating that can change part properties.

When machining, use sharp cutters and set feeds to limit heat. Capture chips and fines with local extraction to protect air quality and finishing.

3D printing, ventilation, and PPE

Place printers in ventilated rooms or enclosures. Use HEPA plus activated carbon filtration to reduce ultrafine particles and VOCs; NIOSH notes these emissions can occur during printing.

Wear respirators rated for particulates and organic vapors when sanding or working near active printers. Add eye and hand protection to lower health risk.

Food-contact selection and end-of-life

For food-contact parts, specify FDA/EFSA‑compliant, BPA‑free grades and vet colorants and additives per manufacturer instructions and guidelines regulations.

Recycle clean scrap where facilities exist; segregate contaminated waste and follow local disposal rules. Keep SDS and compliance certificates ready for audits and quality checks.

Benefits of Using ABS in Manufactured Products

Choose materials that give measurable value—ABS often balances cost, performance, and finish for many products. You get a clear mix of mechanical traits and manufacturability that helps you move from design to production fast.

Performance-to-cost advantages

This engineering plastic delivers good impact resistance and strength at a competitive price. That performance-to-cost ratio makes it ideal for mid-volume production and consumer goods.

Design flexibility and fabrication

You can machine, thermoform, glue, and paint this plastic with predictable results. Thin walls, snap fits, and controlled living hinges are possible with proper DFM and process control.

Consistent finish quality

Parts show reliable surface hardness and surface gloss that help products look premium. Selectable grades—FR, heat-resistant, or platable—let you meet aesthetic, thermal, and health requirements.

Overall, ABS offers a practical path to durable, cost-effective parts across electronics, automotive, and appliance applications while keeping manufacturing efficient.

Machining and Fabrication of ABS: From CAD to Finished Parts

Turn your design into reliable components by focusing on feeds, fixturing, and postwork. Plan cuts and forming steps early so you avoid rework and keep cycle times low for consistent service.

CNC machining: tight tolerances, feeds/speeds, and fixturing

For CNC work use sharp carbide tools and moderate surface speeds to protect part strength. Evacuate chips and use air blast cooling; liquid coolants can cause stress cracking in some abs materials.

Support thin features with soft jaws or vacuum fixtures to prevent chatter and hold tight tolerances for plastic parts used in assemblies.

Thermoforming and vacuum forming best practices

Dry sheets before heating to avoid blistering and aim for uniform heat so wall thinning is minimized. Control mold temperature and vents to capture texture and detail at typical service temperatures.

Bonding, painting, and post-processing for durable finishes

Prep by cleaning and light abrasion, then use ABS-compatible adhesives or solvents for strong joints. Prime before coatings to improve resistance and longevity.

Deburr and polish carefully; consider a low-temperature anneal when tight dimensional control is critical for engineering applications.

Contact Fecision for ABS Parts, Material Guidance, and DFM

Ready to move from design to delivery? Contact Fecision and get fast quotes, design for manufacturability feedback, and prototype support for abs plastic parts.

Send your drawings and we’ll review them under NDA, with engineering checks for tight tolerances (±0.05 mm) and practical DFM notes. Our team helps you choose abs materials and grades like FR, heat‑resistant, platable, or BPA‑free food‑contact compounds.

We handle CNC machining, forming, and finishing for plastic items and cosmetic parts. Ask about texturing, painting, or plating to meet your brand and functional goals. Prototype-to-production support keeps validation simple and lead times short.

For quoting, DFM, or questions on applications abs and material selection, reach out by email and our team will respond with clear timelines and costed options. Expect responsive service from first inquiry through shipment so your items reach market on schedule.