Searching for a metal that undergoes minimal dilation or shrinkage when the temperature fluctuates? Invar provides a near-zero thermal expansion but requires specialized CNC tactics to machine. This unique material is perfect for your precision parts.

This comprehensive guide walks you through Invar CNC machining. We detail the Invar 36 machinability challenges and essential tooling tricks. Knowing these specifics is key for you to achieving successful, stable hardware for your company.

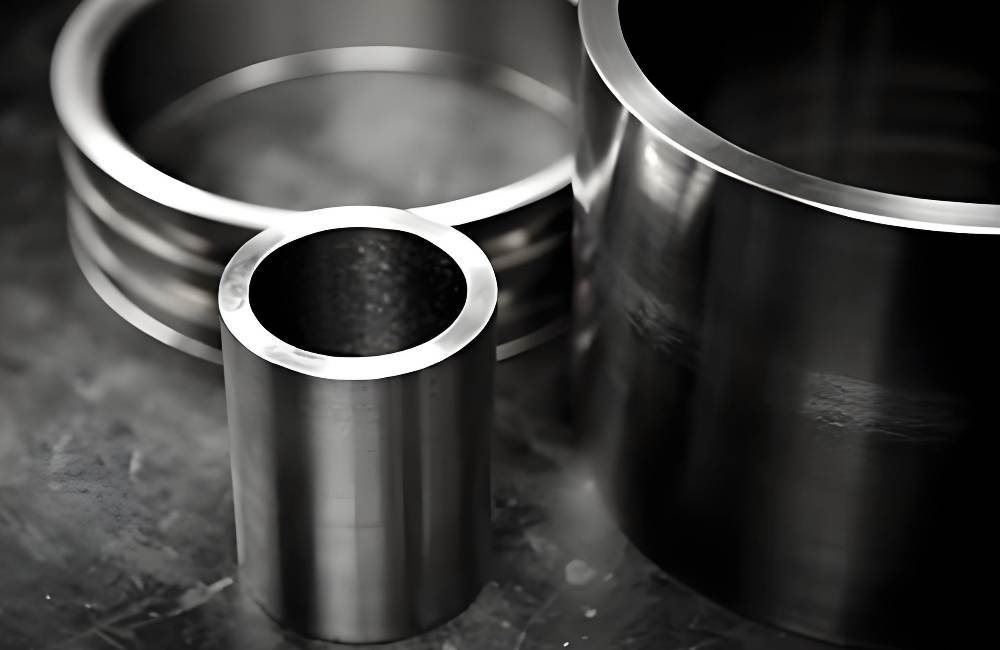

What Is CNC Machining Invar?

CNC machining Invar involves anything from computer-controlled mills and lathes to EDM (Electrical Discharge Machining) to create parts from nickel-iron alloys renowned for their near-zero thermal expansion coefficient. This material is often very sensitive. The nickel-iron material work-hardens in milliseconds under the cutting tool.

To succeed, programmers must carefully balance low speeds, positive feeds, and flood coolant. This strategic approach is necessary to hold micron-level tolerances without the costly mistake of scrapping expensive workpieces.

Different Types of Invar

You will find several cousins of nickel-iron in aerospace, optics, and electronics projects. When you are sourcing material for your next part, knowing these specific Invar grades is absolutely essential for success.

Invar 36 – The Industry Workhorse

Invar 36 is approximately 36% Nickel with the balance being Iron. Its exceptionally low thermal expansion is perfect for many uses. These applications include precision gauges, stable optical benches, and satellite wave-guides. These parts often undergo wide temperature swings, making Invar 36 machining a critical choice for stability.

Super Invar – Ultra-Stable Grade

The composition of Super Invar is adjusted, including Nickel and Cobalt, to keep its Coefficient of Thermal Expansion (CTE) especially low. This ultra-stability is maintained over a wide range, often from cryogenic temperatures up to room temperature. It is commonly used for cryogenic lens mounts and laser resonators. Here, even a micron of drift could cause the laser beams to defocus.

Invar 42 – Glass-to-Metal Match

Containing 42% nickel, Invar 42 has a bit more Nickel than Invar 36. This composition makes its CTE nearly match that of borosilicate glass. This feature is vital for parts like LED seals, vacuum tubes, and MEMS (Micro-Electro-Mechanical Systems) packages. Using Invar 42 means your components can handle thermal cycles without cracking the hermetic seals.

Invar 48 – Ceramic Companion

This variant has an even higher percentage of Nickel (48%), which provides an expansion rate that neatly matches alumina ceramic packages. When CNC-drilled feed-throughs are made in aerospace sensors using Invar 48, they maintain perfect hermeticity. This high reliability is crucial, especially after the parts are subjected to severe thermal shock.

Invar K (Kovar) – Electronic Housing Stalwart

Invar K, or Kovar, uses a balanced blend of 29% Nickel and 17% Cobalt to achieve a CTE that closely matches various types of glass and ceramics. This makes it highly valued in electronics. It is often machined into high-performance microwave transistor carriers and robust X-ray tube windows. Its ability to create a reliable seal is key.

Invar 6 – Controlled Expansion Variant

Invar 6 has a slightly lower Nickel content, resulting in a slight increase in CTE. You’ll get better strength after heat treatment, but keep in mind it still won’t match common steel.. This adds to the economic benefits of using Invar 6 for some applications. For example, it’s ideal for calibration rulers that require predictable and measured lengthening in various conditions.

What Is Invar 36?

Invar 36 is a special type of Iron-Nickel solid-solution alloy meticulously engineered for minimal thermal growth. Its magnetic properties are also notable; the Curie temperature is near 230 °C, causing its magnetic permeability to collapse above this point.

This feature is very useful for non-magnetic optical stages. Its moderate density (~8.1 g/cm³), Young’s modulus (~144 GPa), and yield strength (~275 MPa) provide designers with stable and stiff blanks. Despite its modest mechanical properties, Invar 36 is challenging to cut, requiring specialized techniques due to rapid work hardening and gummy chips.

Invar 36 Machinability Challenges

The unique Invar machining properties that make Invar 36 machining valuable are also the source of its difficulties on the machine floor. Let’s look at the main roadblocks manufacturers face.

Rapid Work-Hardening Under the Cut

The material’s hardness in the shear zone rises dramatically within a very shallow depth. This rapid work-hardening forces subsequent cutting passes to effectively skate on a hardened skin, making the tool tear the material instead of cleanly slicing it. This makes precision difficult.

Gummy, Stringy Chips That Clog Coolant

Invar 36’s high ductility produces long, tangled, and “gummy” chips, often described as a bird’s nest. These chips frequently wrap around the cutting tools, which in turn blocks the vital coolant jets. The result is often the chips being re-cut, causing damage and leaving bruises on the part’s surface.

Built-Up Edge (BUE) Ruins Surface

When cutting at moderate speeds, the nickel-rich chips can chemically weld onto the carbide tool insert. This creates a problematic built-up edge (BUE). The BUE cap repeatedly fractures away from the tool, leaving behind noticeable matte streaks and significantly damaging the intended surface finish.

High Cutting Forces Deflect Thin Walls

The specific cutting energy required for Invar machining is much higher than for austenitic stainless steel. This high force can cause thin ribs and walls to vibrate excessively. This vibration induces unwanted chatter marks or ‘ghosts’ on the surface, which become clearly visible after any final etching processes.

Thermal Conductivity Half of Steel

Invar’s thermal conductivity is about half that of common steel, which will keep generated heat primarily in the shear plane as it is produced during cutting. This heat temporarily expands the tool insert and later shrinks the bored hole. Consequently, a part that measures oversize at room temperature might measure undersize when it is cold.

Expert Tips for Invar 36 Machinability

Overcoming these challenges requires specific process planning and tool selection. Here are the expert tips that guarantee successful machining Invar 36.

Stress-Relief Anneal Before First Cut

Manufacturers should heat the material for two hours at 315 °C and then let it air cool. This crucial step removes the majority of internal residual stress. This ensures that the part’s flatness will hold within a few microns even after significant amounts of stock material have been removed.

Pick Sharp, Positive-Rake Carbide

Manufacturers should use coated carbide inserts that feature a generous positive rake angle and a tiny cutting edge hone. This specific geometry significantly lowers the cutting forces required. It can also effectively double the interval before any built-up edge begins to form on the tool.

Dial in Moderate Speed with Healthy Feed

The manufacturing process requires a sweet spot: a specific band of surface speed combined with a healthy feed per revolution. This optimal combination efficiently evacuates the chips. It is vital to avoid tool dwell, which can cause rapid work-hardening of the surface.

Flood with Ester-Oil Coolant

High-lubricity fluid, often an ester-oil coolant, should be delivered through spiral holes at a pressure of several bars. This strong, focused flow of coolant is vital for breaking the chips into shorter lengths. It also effectively reduces crater wear on the tool insert’s cutting face.

Climb-Mill with Light Axial Engagement

When milling, the manufacturers should use climb-milling techniques with a light axial engagement. This approach keeps the chip thin as it exits the cutting zone, which naturally lowers the height of the resulting burr. This technique can often save time by completely eliminating secondary deburring passes.

Use Trochoidal Toolpaths

Manufacturers should implement trochoidal toolpaths. These toolpaths are designed to maintain a constant chip load on the tool. This reduces the radial engagement of the cutter, significantly boosting tool life and keeping the spindle load steady. A steady load is essential for effectively avoiding chatter marks.

Micro-Peck Drill with Split Point

When drilling, manufacturers should employ short, measured pecks combined with moderate RPM and a low feed per revolution. These steps are necessary to produce clean, shiny hole walls. They also actively prevent the drill from grabbing the material, which is the common cause of small drills snapping.

Post-Machine Stabilisation Bake

After the machining is complete, a low-temperature oven cycle is highly recommended. This process relieves any remaining cutting stresses. For metrology masters, this locks the long-term dimensional change to the parts-per-million (ppm) per year level, ensuring superior, lasting stability.

Need a partner who can manage Invar machinability and complexity? Consult Fecision expert team today for Invar machining service!

Surface Finishes for CNC-Machined Invar Parts

After the machining is finished, you need the right surface finish to protect your part or boost its function. The specific finish you decide to select will always depend on your project’s application.

As-Milled Ra in the Mid-Tenths

The natural as-milled finish, with an Ra (roughness average) in the mid-tenths of a micrometer, is acceptable for many structural parts. It is acceptable for parts such as optical bench brackets with plans to be covered with paint. This option costs you no extra processing fees.

Light Glass-Bead Blast

A light glass-bead blast provides a very consistent surface treatment. This technique effectively hides any minor milling witness marks that remain. It gives the part a uniform satin, non-reflective look, which is perfect for electron-microscope housings and similar sensitive equipment.

Electroless Nickel Layer

Applying an electroless nickel layer adds a durable, hard surface to the Invar machining part. This finish is ideal for avoiding fingerprints and abrasion in clean-room chucks. Importantly, the process is done at a relatively low temperature, typically less than 95°C, thus minimizing thermal stress and helping to maintain the zero-expansion substrate’s stability.

Passivation & Black Oxide

A combination of passivation and a black oxide finish can be used to boost the emissivity of satellite hardware, helping it shed heat effectively. Additionally, this finish prevents galling, a type of friction wear, when the Invar parts are fastened against other materials like titanium.

Single-Point Diamond Burnish

A single-point diamond burnishing process is capable of achieving an extremely fine surface finish, with an Ra value under 0.1 µm on precision bearing seats. This process mechanically compresses the surface layer of the Invar, which can nearly triple the part’s wear life.

Chem-Film for Kovar Blends

A chemical film (Chem-film) process is often applied to cobalt-rich Invar K (Kovar) RF flanges. This finish is essential for protecting the exposed surface and helps keep the microwave insertion loss low. It is a critical step for maintaining high signal integrity in electronic applications.

Applications of Invar Machined Parts

The low expansion of Invar makes it indispensable for mission-critical hardware across various sectors. The following applications highlight why engineers choose Invar machinability.

Aerospace Composite Lay-Up Molds

Invar 36 is widely used by manufacturers for creating mold tools for composite lay-up in aerospace. The superior stability of these molds means they hold a tight profile across the entire cure cycle. This stability dramatically reduces the need for manufacturers to do costly, time-consuming autoclave re-shimming.

Satellite Wave-Guide Filters

Super Invar is the material of choice for waveguide filters in satellites. These blocks are machined to tolerances of only a few microns. This precision ensures that the critical Ka-band frequencies remain exactly within specification, even after significant orbital temperature swings.

Cryogenic LNG Flow Meters

The turbine rotors in flow meters designed for Cryogenic Liquefied Natural Gas (LNG) are often made from Invar 42. This material guarantees your rotors remain perfectly concentric at extremely cold temperatures, preventing calibration drift.

Bimetal Thermostat Rods

Invar 6 is utilized as the core material inside brass tubes to create bimetal thermostat rods. The difference in thermal expansion between the Invar 6 and the brass creates a predictable stroke, which is perfectly suited for reliably controlling modern HVAC mixing valves.

Precision Etch Frames for OLED Masks

Machining Invar 36 is the industry standard for the precision stencil frames used in manufacturing OLED masks. These frames are essential for maintaining the exact pixel pitch across large display panels. They are crucial during the intricate vapor deposition process, which ensures you get flawless screens.

Scientific Metrology Standards

Stress-relieved Invar 36 is transformed into highly stable gauge blocks and other scientific metrology standards. These blocks are capable of holding micro-inch flatness for decade-long recertification cycles, serving as the benchmark for industrial measurement accuracy.

Start Your CNC Machining Invar Project with Fecision

Invar’s rapid work-hardening and tight tolerance demand advanced CNC technology. Fecision utilizes multi-axis machines from 3-axis to 5-axis to achieve the complex cuts and geometries necessary for Invar machining needs. We can achieve tolerances of ±0.0001″ to provide stable, high-quality hardware.

Machining Invar entails expert process planning, including stress-relief annealing and controlled feeds. Our ISO-certified quality assurance and experienced engineering team specializes in DFM for complex nickel alloys. We guarantee fast turnaround times for your cryogenic, optical, or aerospace Invar components, ensuring superior results.

Partner with Fecision today for premium Invar machining services! Get a quote and see the difference precision engineering makes.