In injection molding, the runner system is like the highway that delivers molten plastic from the machine nozzle to the part cavity. A well-planned injection molding runner ensures smooth flow, balanced filling, and consistent part quality. A poor runner, on the other hand, causes defects, longer cycle time, and unnecessary waste.

Because the runner in injection molding directly affects pressure loss, cooling rate, and material usage, its design is a key driver of cost and production efficiency. This article explores the different types of runner in injection molding, key principles of injection mold runner design, and common design mistakes to avoid them.

What Is a Runner in Injection Molding?

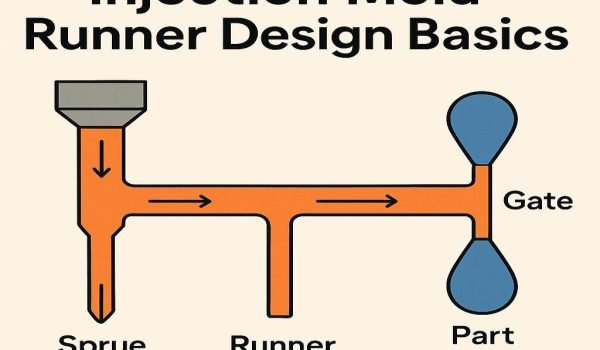

A runner in injection molding is a flow pathway machined into the mold that distributes melt from the sprue to one or more gates. Together with the sprue and gates, runners form the “feed system” that controls how plastic enters the part cavity. The goal of a plastic injection mold runner design is simple to deliver molten polymer at the right temperature, pressure, and speed so cavities fill evenly and consistently.

Runner vs. Sprue vs. Gate

Sprue: The main vertical channel connected directly to the machine nozzle. It feeds material into the runner system.

Runner: Horizontal or branched channels that distribute melt from the sprue to gates.

Gate: The final small opening where melt enters the cavity; it controls fill pattern and packing.

Think of the sprue as a trunk, runners as branches, and gates as leaves. If the branches are poorly shaped or uneven, the leaves won’t get the same supply.

Why proper runner design is critical

Mold runner design is critical because runners determine filling balance, pressure drop, shear heat, and cooling behavior. If the runner network is too long, too narrow, or unbalanced, the melt may arrive late or cool prematurely, leading to shorts, sink, dimensional mismatch, or flashing. Great injection molding runner design translates directly into stable production, high yield, and predictable cycle times.

Functions of an Injection Molding Runner System

An injection molding runner system does much more than “carry plastic.” First, it distributes melt evenly to one or multiple cavities so each cavity fills at the same time. This ensures dimensional consistency across parts in family molds or multi-cavity molds.

Second, runners help control pressure and flow rate. Their size and geometry regulate resistance, shear, and the speed at which plastic reaches the gates. Proper plastic injection mold runner design ensures enough pressure is retained for packing, reducing sinks and voids.

Third, runner design influences melt temperature stability. As plastic flows, it loses heat to steel. A well-designed runner minimizes temperature drop and avoids overly high shear that could degrade material.

Finally, runners affect cycle time and cost. Runners solidify and must cool before ejection in cold systems; oversized runners can add seconds to every cycle. In hot systems, runners stay molten and remove scrap costs. Either way, the runner layout is a key lever for productivity.

Types of Runners in Injection Molding

There are two main runner categories: cold and hot runners. Each has its own structure, cost, and application advantages.

1) Cold Runner Mold Design

A cold runner mold design uses unheated channels. Plastic flows through the sprue and runners, fills the cavities, and then cools and solidifies along with the parts. When the mold opens, the runner is ejected as solid scrap (unless re-ground and reused).

Cold runners are simple, reliable, and widely used in standard molding operations. The runner network is machined directly into the mold plates, meaning no additional heating equipment is required. The system depends on correct sizing and layout to avoid premature freezing or pressure imbalance.

Advantages:

- Lower tooling cost.

- Easier to build and repair.

- Simple maintenance and high reliability.

Disadvantages:

- Runner scrap wastes material.

- Longer cycles due to runner cooling.

- More post-processing (runner separation).

Cold runners are ideal for low-to-medium volume production, large parts, or situations where tooling budget is limited.

2) Hot Runner Mold Design

A hot runner mold design keeps the runner channels heated so the plastic stays molten throughout the system. No runner wastes and only the finished parts are ejected. This system uses manifolds, heated nozzles, and temperature controllers.

Hot runners are built as separate heated assemblies installed inside the mold. They allow controlled melt flow, reduce pressure drop, and support more advanced gating methods. Because plastic does not solidify in the runner, melt consistency and cycle time improve dramatically.

Advantages:

- No runner waste (material savings).

- Faster cycles, especially for thin parts.

- Better surface finish and fewer gate marks.

Disadvantages:

- Higher initial tooling cost.

- More complex to maintain.

- Requires skilled setup and temperature tuning.

Hot runners are best for high-volume production, multi-cavity molds, and expensive engineering plastics where material waste is costly.

Key Elements of Plastic Injection Mold Runner Design

Strong plastic injection mold runner design is a balance between flow efficiency, thermal behavior, manufacturability, and cost.

1. Runner Layout

The layout defines the shape and structure of runner channels. A balanced layout ensures equal flow paths and distances to all cavities. Typical layouts include H-shaped, X-shaped, and spoke-type configurations. A balanced layout minimizes pressure variation and ensures consistent cavity filling.

2. Runner Size and Cross-Section

Cross-sectional shape determines flow efficiency. Common profiles include full-round, trapezoidal, and modified rectangular. Of these, full-round cross-sections offer the highest flow rate per unit area, making them ideal for minimizing pressure drop. Runner diameter must balance flow capacity and cooling speed, too large increases cycle time; too small increases injection pressure.

3. Runner Length and Pressure Drop

The longer the runner, the greater the pressure loss. This affects both flow balance and material temperature. Designers must minimize unnecessary runner length while ensuring geometric symmetry for balanced filling. Computational simulations help predict pressure distribution across runner networks.

4. Gate Location Connection

Gate design and location heavily influence how molten plastic enters the cavity. Runners must connect to gates in smooth, streamlined transitions to avoid stagnation points and turbulence. Poor transitions result in cosmetic issues, weld lines, and internal stress within the finished part.

Best Practices for Mold Runner Design

Successful plastic injection mold runner design is all about balancing competing factors. Here are proven best practices used in modern injection molding runner design:

- Design for balance first: Balanced runners prevent cavity-to-cavity variation. For symmetrical molds, equal lengths are ideal. For asymmetrical layouts, diameter tuning may be needed.

- Keep runners as short as possible: Short runners reduce pressure loss and cooling issues, helping improve process stability.

- Choose the right cross-section: Full round or trapezoidal runners usually outperform rectangular due to lower resistance.

- Avoid sharp corners: Sharp turns create high shear and pressure loss. Add generous radii and smooth directional changes.

- Use gradual transitions: Sudden size changes cause turbulence, jetting, or hesitation. Use tapering and smooth step-downs.

- Match runner design to material: High viscosity resins (like PC or filled nylons) need larger runners. Low viscosity materials (like PP) tolerate smaller ones.

- Consider venting and air traps early: Balanced runners still fail if air can’t escape. Venting strategy should be checked with runner and gate placement.

- Simulate before cutting steel: Moldflow or similar CAE tools reveal imbalance, pressure loss, weld lines, and freeze-off risk before you commit to machining.

These practices apply to both cold runner mold design and hot runner mold design, though hot runners allow more flexibility in layout because temperature is controlled.

Common Injection Molding Runner Design Mistakes (and Fixes)

Even good molds fail if runner decisions are rushed. Here are the big mistakes and how to correct them.

1) Oversized runners

Oversized runners increase plastic volume that must cool (in cold runner mold design). That means slower cooling, longer cycles, and more wasted material. You may also see higher clamp tonnage requirements due to excess pressure and flash risk.

Fix: Reduce runner diameter and shorten flow paths. Re-check the fill balance after resizing. A smaller runner that still avoids freeze-off is almost always better.

2) Undersized runners

If the runner is too small, the melt freezes early, causing short shots or requiring extremely high pressure. This can lead to burn marks, part stress, and uneven packing.

Fix: Increase cross-section gradually. Don’t jump to huge sizes, step up carefully and confirm the pressure drop improves while maintaining balanced fill.

3) Unbalanced runner networks

Unbalanced runners cause uneven filling. Some cavities pack earlier, others lag behind, leading to size mismatch, weight variation, warpage, or sink differences.

Fix: Follow a balanced runner layout where possible. If geometry prevents that, tune runner diameters to equalize pressure drop and fill time.

4) Poor transition areas

Sharp corners, sudden diameter changes, or dead pockets create turbulence, shear spikes, and freeze-off points. You’ll see flow lines, burn, or inconsistent fill.

Fix: Add radii, smooth tapers, and consistent cross-sectional changes. Every transition should feel like a gentle river, not a waterfall.

Conclusion

A well-engineered injection molding runner is the foundation of stable, high-quality molding. A properly engineered runner in injection molding ensures balanced filling, stable pressure, shorter cycle times, and better part quality. Choosing between the types of runner in injection molding, cold or hot, depends on production volume, material cost, and tooling budget. You can reduce waste and defects dramatically by following proven plastic injection mold runner design rules and avoiding common mistakes.

If you need expert support, Fecision mold manufacturing service can help you design and build runner systems optimized for your exact parts and production goals. Contact us anytime to get started.