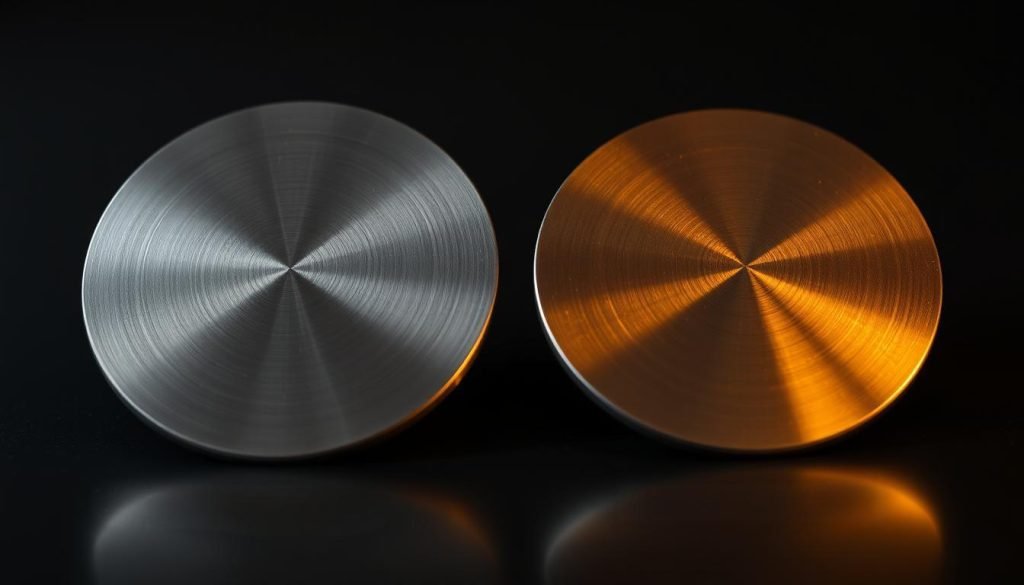

Choosing the right material for your project can make all the difference. Nickel-based superalloys are known for their exceptional performance in extreme environments. Two of the most widely used alloys in this category are Inconel 718 and Inconel 625. Both offer high strength and corrosion resistance, making them ideal for demanding industries.

These superalloys play a critical role in aerospace, marine, and energy sectors. Inconel 718, for example, is found in 30% of modern aircraft engine components. Inconel 625, on the other hand, is often used in marine and oil applications due to its adaptability. Understanding their unique properties can help you make an informed decision.

Whether you’re working on aerospace engineering or oil and gas projects, selecting the right nickel alloy is crucial. This article will explore the key differences between these two materials, helping you determine which one suits your needs best.

Introduction to Inconel 718 and Inconel 625

Understanding the origins of these alloys can help you appreciate their unique properties. Inconel 625 was first developed in the 1950s for steam-line piping in power plants. Its excellent corrosion resistance later made it a go-to material for marine applications.

Inconel 718, on the other hand, was discovered by accident during research on its counterpart. Its ability to resist creep rupture up to 1,300°F quickly made it a staple in aerospace engineering. Both alloys are part of the nickel chromium family, known for their durability in extreme conditions.

When comparing their compositions, Inconel 625 focuses on chromium and molybdenum niobium for strength. Inconel 718 incorporates iron and niobium, giving it unique precipitation hardening capabilities. This makes it ideal for high-stress environments.

Inconel 718 vs Inconel 625: Material Properties Comparison

Material properties play a crucial role in determining the right alloy for your needs. By examining the chemical composition, mechanical properties, and corrosion resistance, you can make an informed decision tailored to your project requirements.

Chemical Composition

The chemical composition of these alloys reveals their unique strengths. Alloy 625 contains 58% nickel, 20-23% chromium, and 8-10% molybdenum. This combination enhances its resistance to harsh environments, especially those with high chloride content.

Alloy 718, on the other hand, has 50-55% nickel, 17-21% chromium, and 4.75-5.5% niobium. The addition of niobium allows for precipitation hardening, making it ideal for high-stress applications.

Mechanical Properties

When it comes to mechanical properties, Alloy 718 stands out with a tensile strength of 1,275 MPa. This makes it a top choice for aerospace and high-temperature applications. Alloy 625, with a tensile strength of 690 MPa, is better suited for environments requiring flexibility and durability.

Alloy 625 uses solid-solution strengthening, which provides excellent stability. Alloy 718 relies on precipitation hardening, offering superior strength under extreme conditions.

Corrosion Resistance

Corrosion resistance is a key factor in material selection. Alloy 625 excels in chloride and saltwater environments due to its higher chromium and molybdenum content. This makes it a preferred choice for marine and oil industries.

Alloy 718, while strong, has a lower oxidation resistance limit of 1,300°F compared to Alloy 625’s 2,000°F. However, its unique composition ensures excellent performance in high-stress, high-temperature environments.

Machinability of Inconel 718 vs Inconel 625

When working with advanced materials, understanding their machinability is key to project success. Both alloys present unique challenges and advantages during machining, forming, and welding. Knowing these differences can help you optimize your manufacturing process.

Formability and Weldability

Formability is a key factor when shaping these alloys. Both materials can be cold formed, but the 718 inconel maintains its strength after shaping. This makes it ideal for high-stress applications where structural integrity is critical.

Weldability is crucial for applications requiring strong, seamless joints. The 718 inconel excels here due to its resistance to post-weld cracking. This property makes it a preferred choice for aerospace assemblies and other welded structures.

Heat Treatment

Heat treatment processes differ significantly between these materials. The 625 alloy requires solution treatment at 2,000°F, which enhances its corrosion resistance and stability. On the other hand, the 718 inconel uses aging treatments up to 1,400°F, which improve its strength and durability.

Both alloys benefit from their respective heat treatment methods. However, the 718 inconel’s two-phase heat treatment process provides superior performance in high-stress environments.

When machining these materials, work hardening can be a challenge. Using the right cutting tools and techniques is essential. Carbide tools are often recommended for both alloys, but specific coatings can improve performance.

For forming, optimal temperature ranges are critical. Bending and rolling should be done within specific limits to avoid cracking or weakening the material. Proper planning ensures the best results for your project.

Common Uses for Inconel 718 and Inconel 625

Nickel-based superalloys are essential in industries where extreme conditions demand top performance. These materials are widely used in aerospace, oil and gas, marine, and automotive sectors. Their unique properties make them ideal for high-stress and corrosive environments.

Aerospace Industry

The aerospace industry relies heavily on these superalloys for critical components. Jet engine parts, such as turbine disks and rocket motor casings, often use these materials. Their ability to withstand high temperatures and stress ensures reliable performance in flight.

Oil and Gas Industry

In the oil and gas industry, these alloys are crucial for offshore drilling and subsea operations. Subsea wellhead equipment and seawater propeller shafts are often made from these materials. Their resistance to corrosion ensures longevity in harsh marine environments.

Marine and Automotive Industries

The marine industry uses these alloys for propeller blades and shipboard sensors. Their resistance to saltwater corrosion makes them ideal for long-term use in the ocean. These materials ensure that marine vessels operate efficiently and safely.

In the automotive sector, high-performance turbochargers often incorporate these superalloys. Motorsport applications, such as F1 exhaust systems, benefit from their strength and heat resistance. The automotive industry continues to explore new ways to utilize these advanced materials.

Power generation and nuclear applications also rely on these superalloys. Their ability to perform under extreme conditions makes them a valuable asset in these critical industries. Whether in aerospace, oil and gas, or marine and automotive sectors, these materials play a vital role in modern technology.

How to Choose the Right Inconel Alloy

Selecting the right alloy for your application ensures optimal performance and longevity. To make the best choice, consider factors like temperature, stress, and corrosion resistance. Each material excels in specific environments, so understanding their strengths is key.

For high-temperature applications above 1,300°F, the difference in inconel 625 makes it the better option. Its superior resistance to stress corrosion cracking also makes it ideal for harsh environments like seawater. If your project involves high tensile loads, alloy 718 is the stronger choice due to its exceptional strength.

When comparing seawater and chemical plant environments, the difference in inconel 625 becomes even more apparent. Its higher chromium and molybdenum content provide excellent corrosion resistance in chloride-rich settings. Alloy 718, while strong, is better suited for high-stress applications in less corrosive environments.

Cost is another important factor. Alloy 718 requires complex heat treatment processes, which can increase expenses. In contrast, the simpler processing of alloy 625 makes it a more cost-effective option for many projects.

Finally, avoid substituting alloys in FDA-regulated applications. Each material has specific certifications, and using the wrong one could lead to compliance issues. By carefully analyzing your project’s needs, you can choose the alloy that delivers the best results.

Conclusion

Deciding between these two advanced alloys requires careful consideration of their unique strengths. If your project demands superior corrosion resistance, especially in high-temperature environments up to 1800°F, one alloy stands out. For applications needing unmatched tensile strength, the other is the clear choice.

To make the best decision, evaluate factors like temperature, stress levels, and environmental conditions. Consulting with metallurgical experts can provide valuable insights tailored to your specific needs. Both alloys comply with ASTM and AMS standards, ensuring reliability across industries.

Finally, consider testing material samples to confirm their suitability for your project. This step ensures optimal performance and cost-effectiveness. By carefully analyzing these factors, you can choose the alloy that best meets your requirements.