Powder coating is a specialized finishing process that provides superior durability and aesthetic appeal for your vehicle’s wheels.

With its outstanding corrosion protection, weather resistance, and ease of cleaning, it’s no wonder that many car enthusiasts and professionals are turning to this method.

The process involves preparation, sandblasting, applying a durable coating, and curing in an oven, resulting in a long-lasting finish.

Whether you’re looking to refresh your current wheels or completely transform their appearance, understanding the powder coating process can help you achieve professional-quality results.

Understanding Powder Coating for Wheels

Powder coating is a revolutionary method for giving your wheels a durable and attractive finish. It’s a dry finishing process that uses finely ground particles of pigment and resin.

What Is Powder Coating?

Powder coating is achieved by combining special polymers together through a heating

process to create one finished protective layer. This process is more environmentally friendly than traditional liquid paint because it doesn’t require a solvent.

How Powder Coating Works

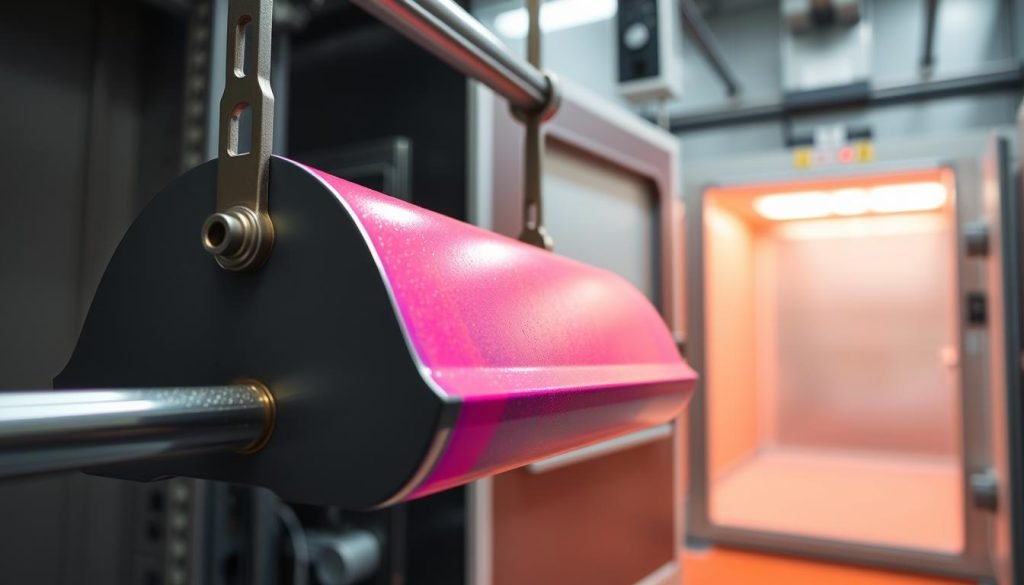

The wheel is grounded, and the powders get a special charge applied to them, attracting them to the grounded metal. Once applied, the coated wheel is heated in an oven where the powder melts and forms a “skin” that adheres to the surface, creating a hard finish that’s tougher than conventional paint.

Benefits of Powder Coating Your Wheels and Rims

Powder coating is a game-changer for wheel customization, offering a range of benefits that traditional painting methods can’t match. When you choose to powder coat your wheels, you’re investing in a superior finish that enhances both the durability and appearance of your vehicle.

Superior Durability and Protection

Powder coating provides a thick, uniform coat that acts as a robust barrier against corrosion, rust, and extreme weather conditions. This results in a finish that can withstand road salt, UV exposure, and chemical contact without degrading, significantly extending the lifespan of your wheels – potentially up to 20 years with proper care.

Aesthetic Advantages

Aesthetically, powder coating offers a wide range of color options, finishes, and special effects, allowing for complete customization of your wheels. The finish achieved is smoother and more uniform than traditional paint, with no drips or sags, enhancing the overall appearance and quality of your vehicle’s wheels.

Environmental Benefits

From an environmental perspective, powder coating is more eco-friendly than traditional painting methods. It contains no solvents, produces minimal waste, and releases virtually no volatile organic compounds (VOCs). The powder that doesn’t adhere during application can be collected and reused, further reducing waste and making the process more sustainable.

Essential Tools and Materials for Powder Coating

The right equipment and materials are vital for achieving a professional-grade powder coat on your wheels. To get started, you’ll need to set up a proper workspace with the necessary tools.

Required Equipment

You’ll need a sandblasting cabinet to thoroughly clean and texture the wheel surface, a powder coating booth to contain the powder, and a curing oven that can reach 400°F to cure the coat. Proper ventilation equipment is also necessary to prevent inhalation of airborne particles.

A powder coating gun applies an electrostatic charge to the powder particles, ensuring a uniform coat. A curing oven, either dedicated or a modified kitchen oven, is required for the curing process.

Powder Coating Materials

Essential materials include automotive-grade powder coatings, high-temperature masking tape and plugs, grounding wires, and cleaning solvents. Personal protective equipment like respirators, gloves, and eye protection are also crucial for safety.

The powder coating medium comes in various formulations for different applications and finish types. For wheels, automotive-grade powder coatings are recommended for their durability.

Preparing Wheels for Powder Coating

Preparing your wheels for powder coating is a crucial step that requires attention to detail. To achieve a high-quality finish, you must thoroughly prepare the surface of your wheels.

Cleaning and Stripping the Wheels

The first step in preparing your wheels is to clean and strip them. This involves removing dirt, grease, brake dust, and road grime using appropriate degreasers and cleaners. For wheels with an existing finish, this layer must be completely removed through chemical stripping or mechanical methods.

Sandblasting Process

Sandblasting is the preferred method for creating an ideal surface profile. It removes previous finishes and exposes bare metal, allowing the powder coating to adhere properly. Be methodical and thorough when sandblasting to ensure every surface is treated.

Repairing Damage and Imperfections

After sandblasting, inspect your wheels for damage such as curb rash, cracks, or bends. Minor imperfections can be filled with specialized metal fillers designed to withstand high temperatures. Once repairs are complete, clean the wheels again to remove any residual blast media or dust.

How to Powder Coat Wheels and Rims: Step-by-Step Process

The process of powder coating wheels involves several key steps that ensure a durable and attractive finish. To achieve professional-looking results, it’s crucial to follow these steps carefully.

Setting Up Your Workspace

Begin by setting up a clean, well-ventilated workspace with proper lighting. Ideally, use a dedicated powder coating booth that contains the powder and provides optimal application conditions. Ensure your curing oven is preheated to the temperature specified by your powder coating manufacturer, typically around 400°F.

Masking and Hanging the Wheels

Properly mask areas of the wheel that should not receive coating, including mounting surfaces, lug holes, and valve stems, using high-temperature tape and silicone plugs. Create a hanging system that allows the wheels to be suspended freely while maintaining a ground connection.

Applying the Powder Coat

When applying the powder coat, use smooth, even passes with your powder gun, maintaining a consistent distance from the wheel surface. Focus on applying the powder to all visible surfaces first, then rotate the wheel to access recessed areas and the backside. Avoid applying excessive powder to prevent runs or uneven curing.

Curing Process in the Oven

Once the wheel is fully coated, carefully transfer it to the preheated oven without disturbing the powder. The curing process typically takes 18-22 minutes at 400°F. Monitor the curing process closely to avoid under-curing or over-curing, which can result in a finish that’s not fully hardened or cause yellowing.

Timeframe and Longevity of Powder Coated Wheels

If you’re planning to powder coat your wheels, it’s essential to understand the time required for the process and its expected lifespan. The duration of the powder coating process can vary based on several factors, including the condition of the wheels and the equipment used.

How Long Does the Powder Coating Process Take?

The complete powder coating process for a set of four wheels typically takes 1-2 days from start to finish when done professionally. For a single wheel, the process takes approximately two hours from preparation to final cooling. The preparation phase is the most time-consuming part, taking 30-60 minutes per wheel. The actual powder application is relatively quick, taking only 10-15 minutes per wheel.

Expected Lifespan of Powder Coated Wheels

Powder-coated wheels typically last three times longer than traditionally painted wheels, with a potential lifespan of up to 20 years under ideal conditions. The exceptional durability comes from the chemical bonding process that occurs during curing. Factors such as exposure to harsh chemicals, extreme environmental conditions, and physical damage can affect the lifespan of powder-coated wheels.

Conclusion

Powder coating wheels and rims is an effective way to enhance your vehicle’s appearance and durability. By following the multi-step process outlined in this article, you can achieve a professional-grade finish that outperforms traditional painting methods. The superior durability of powder coating makes it particularly valuable for wheels exposed to harsh conditions. With proper care, your powder-coated wheels can last up to 20 years, making it a worthwhile investment.