Mold design is a very important process in plastic injection molding. The well-designed mold was conducive to the improvement in the production capacity, the quality of the parts, and the cost of manufacture. The design should have complexity but without compromising practicality, taking into consideration the application demands and production volume. Critical considerations in mold design are material flow, cavity and core geometry, cooling system and ejection.

All aspects impact the quality of the final product, as well as the lifespan and maintenance of the mold. By knowing these, mold designers can optimize performance and consistently generate parts.

This Article explores the key factors in designing molds for plastic injection and focuses on best practices that improve productivity and product quality in today’s manufacturing.

Injection Molding Design Basics

When you plan to create a new mold for plastic injection molding, it can be a difficult decision to make as the mold may be very complex, and the cost may naturally be high. The mold needs to faithfully reproduce the design of the part and, at the same time, facilitate an efficient production process. Important factors include wall thickness (if too thin, it would not be able to support the part), draft angles, parting lines and gate locations. This affects the flow of material, cooling, and the ejection of the parts.

Uniform wall thickness prevents defects like warpage and sink. Draft angles help to release the part from the mold without being damaged. The correct location of parting lines has an impact on mold building and part appearance. Gate design determines how the molten plastic enters the mold; Flow and quality are affected by flow.

Key design considerations include:

- Simplicity: Aim for the simplest mold design that meets functional requirements.

- Functionality: Ensure the mold allows for proper filling, cooling, and ejection.

- Cost-effectiveness: Balance mold complexity with manufacturing budget and volume needs.

Technical complexity versus production is the balance to maintain. Thou highly detailed molds may make exacting parts, they can be expensive and lead to a prolonged cycle time. Simple geometries can cut down on tooling costs and can speed production, if to the detriment of some part features.

Designing for Efficient Mold Flow

Efficient flow of matter is essential in the design of injection molds. Correct flow leads to the full and complete fill of molten plastic throughout the mold; it also prevents all defects related to filling, such as short shots, warping and silver streaks. In designing molds housing those cavities, engineers seek to provide smooth, clear pathways in which the viscous resin may travel from the point of injection to every portion of the cavity.

The one thing to keep in mind is the runner and gate design. Runners are the pathways that direct the molten plastic from the nozzle to the cavity, and gates determine the flow into the mold. A runner system can be appropriately designed to ensure the equilibrium of filling in multi-cavity molds by controlling the flow from the runner to each cavity. Gates need to be located/cut strategically to minimize flow resistance and the formation of weld lines, which are areas where fronts of material meet.

Techniques to optimize flow paths include:

- Using gradual transitions: Avoid sharp corners or sudden changes in runner size to maintain a steady flow.

- Balancing runner lengths: Ensure all cavities fill at the same rate by equalizing runner lengths and cross-sectional areas.

- Gate placement: Position gates to promote smooth filling and reduce air traps.

Furthermore, molding designers can select suitable values of flow-channel dimensions by taking into account the viscosity and melt temperature of the material. Cooling devices are also disposed of adjacent to the flow paths for solidifying the resin uniformly and preventing deformation.

By optimizing mold flow, the manufacturer obtains improved part quality, shorter cycle time and less waste. Its efficient flow design cushions production by further enhancing the overall performance of the process.

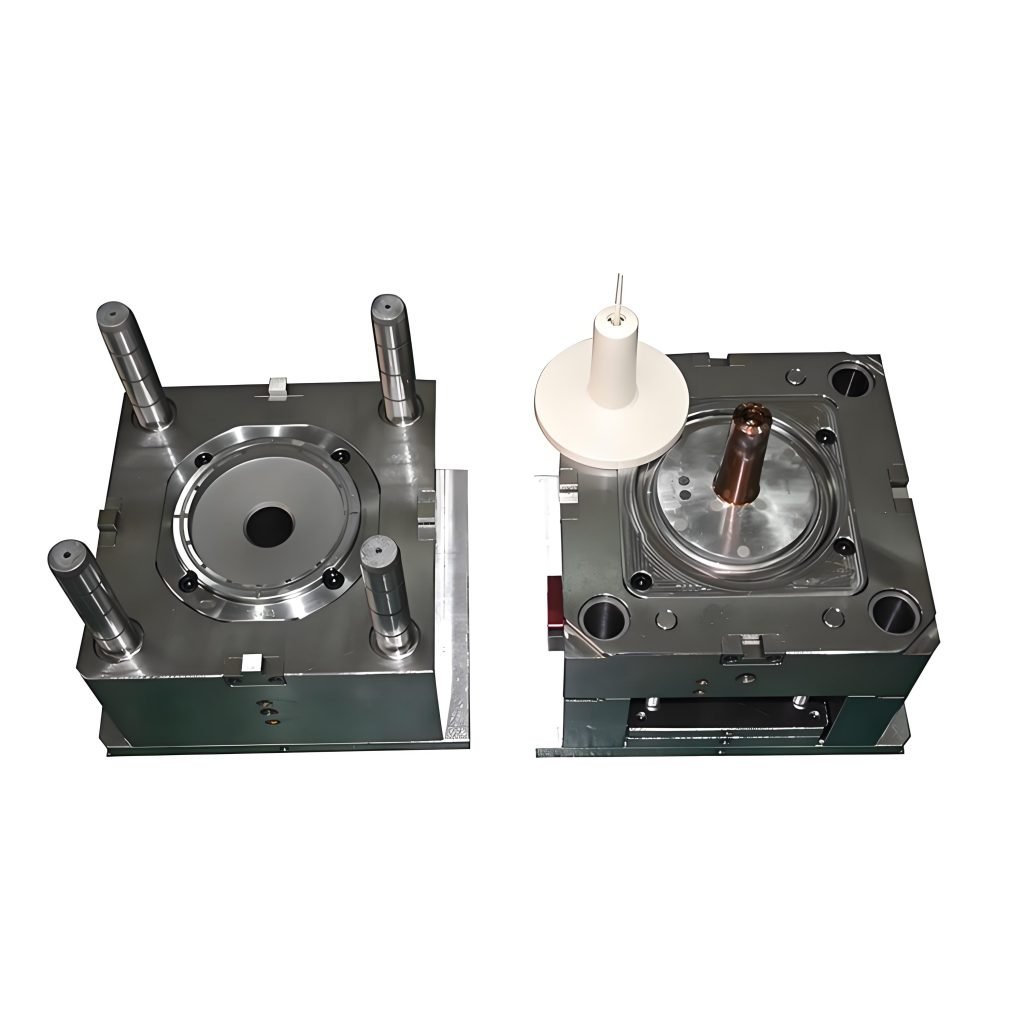

Mold Cavity and Core Design

The cavity and core are the two basic parts of the cavity that construct the final plastic part by injection molding. The cavity becomes the exterior, while the core shapes the interiors or hollow areas. Both need to be correctly designed in order for accurate dimensions, good finishes, and void-free products to be obtained.

The part’s geometry and function need to be taken into account when designing the cavity and core. The cavity should be shaped to provide the external features as described evolved in it with adequate room for the melt to flow and for cooling. The core must accommodate internal features such as holes, ribs or undercuts. Many times, these features are modeled very accurately using sophisticated CAD tools by designers.

The position of the cavity and core mold impact mold assembly and part ejection. Even clamping pressure — resists stress on the mold, overcomes platen wear, and regulates cooling. Warping or shrinking can occur due to uneven cooling of the part, causing the shape of the part to be distorted.

Another significant parameter is the surface finish on the cavity and core. Smooth finishes are great for reducing friction and producing a smooth, consistent, even surface by preventing whatever you are molding from clinging to the mold during ejection. Textured finishes can be included for appearance and/or utility characteristics in the product, but these also have to be carefully designed to avoid defects.

The cavity and core should be designed with the proper tolerances to give a tight fit and minimize flash or gapping between mold components. And the right draft angles, of course, let parts release without breaking.

In short, the mold cavity and core directly on the quality and the function of the part. Skillful design can optimize dimensional accuracy, surface quality, and production efficiency.

Cooling and Ejection Systems

Cooling and ejecting are two of the most important functions in the mold design that have a direct impact on the cycle time, part quality, and production rate. In order to avoid problems such as warping, sink marks or even internal stress, sufficient cooling times have to be followed. In the meantime, an efficient ejection system ensures the part can be easily ejected without damage or distortion.

Usually, the cooling is done by passing the coolant (e.g., water, water with glycol, or oil) through channels in the mold. These channels have to be located in the area near the core and cavity to dissipate the heat efficiently. Even cooling allows for consistent part size and shorter cycle times. The use of simulation software for optimal cooling channel design, such as pattern, size, and flow, is a common practice among engineers.

Configuration of ejection systems will depend on part complexity and tool design. Typical mechanisms are ramps, sleeves and stripper plates. Ejector pins are used to eject the part out of the mold after it solidifies. Sleeves can lead to the liberation of undercuts or more complicated shapes. Stripper plates apply uniform force to spare the part during ejection.

Designers are required to ensure that the ejector acts with balance in the ejection system, which can prevent makings or deformation from emerging on the part surface. Correct timing of scanning movement in the molding cycle is also critical in order to prevent sticking.

In general terms, good cooling and ejector systems create a more efficient mold with better-quality parts. They create additional value by shortening cycle time and helping parts to release gently, allowing high-volume production with low defects.

Material Selection and Mold Durability

The choice of materials for mold components is critical for the guarantee of durability and trustworthy performance. Mold components need to be able to withstand high pressure and heat and also be able to be used over and over without becoming deformed or worn. Widely used materials are Hardened steel, Stainless steel, and Aluminum. All these materials have with own different benefits.

It is made from hardened steel, known for its strength and resistance to wear. It is suitable for high-volume molds or with abrasive materials. The stainless steel provides good corrosion resistance and is suitable for molding corrosive materials, such as algae, which can lead to corrosion of standard hardened steel molds, or for use in wet environments. They also wear faster than steel molds and are more costly short run or prototype production.

The durability also relies on the mold design and maintenance. Adequate cooling decreases thermal stress and increases the life of the mold. Regular maintenance and cleaning reduce the risk of the effects of residue or corrosion.

Final Thoughts

The mold’s powerful design plays an important role in ensuring the success of plastic injection molding. It affects the quality of the part, productivity and mold life. Critical factors, including material process, mold core and cavity design, cooling system and ejection, must be addressed and balanced. Selecting materials that are not only tough but have longevity ultimately optimizes mold performance and minimizes maintenance.

Fecision is especially good at high-end mold design schemes and provides products with precision and class for the customer. Their experience provides efficient production of high-quality parts in every job. Knowledge and use of good techniques for mold design allow for more cost-effective production with fewer defects, allowing for competitive production in the modern market.