As an important foundation of modern manufacturing, injection molding technology has become the core method for large-scale production of plastic parts with its advantages of high precision and high efficiency. However, in actual applications, manufacturers and engineers often ask such questions: “How much does injection molding cost?” In reality, material selection, part complexity, production volume, and other factors significantly impact the injection molding cost.

This comprehensive guide explores key cost factors, shares hands-on strategies for savings, and explains why partnering with experts like Fecision delivers top quality while boosting cost efficiency – a smart move for real-world production.

Is Injection Molding an Expensive Process?

Determining whether injection molding is expensive depends on specific circumstances. From a long-term production perspective, the process itself is not costly.

Despite high initial setup costs for mold manufacturing and machine calibration, plastic injection molding becomes highly economical at scale. In small production runs, the per-unit cost is relatively high due to the fixed costs being distributed across fewer parts. However, as output increases significantly, the per-unit cost drops sharply, showcasing the critical role of economies of scale. Once mass production begins, the fixed costs of molds and equipment are amortized over a much larger quantity, making injection molding a cost-effective solution for high-volume manufacturing.

Key Factors Influencing Injection Molding Cost?

The cost of injection molding for your project is influenced by a multitude of critical determinants, and gaining a thorough grasp of these elements is essential for maintaining effective budgetary control.

Material Costs

Material costs are a major factor in injection molding budgets. While high-performance plastics increase expenses, smart design and efficient processes can minimize material use and waste, cutting overall costs. Meanwhile, eco-friendly and recyclable materials may cost slightly more upfront but support sustainable manufacturing—offering both environmental benefits and long-term economic value.

The table below shows the cost variation across common plastic materials:

| Material | Approximate Cost Range(USD/kg) |

| Polypropylene (PP) | 2.00 – 4.00 |

| Acrylonitrile Butadiene Styrene (ABS) | 2.50 – 5.00 |

| Nylon | 3.30 – 5.50 |

| Polycarbonate (PC) | 3.50 – 7.50 |

| High Impact Polystyrene (HIPS) | 2.30 – 3.70 |

| Thermoplastic Rubber (TPR) | 2.50 – 4.50 |

| Polyoxymethylene (POM) | 3.00 – 5.00 |

| Thermoplastic Polyurethane (TPU) | 3.50 – 6.50 |

| Acrylic | 3.00 – 4.50 |

| Polyethylene (PE) | 1.70 – 3.00 |

Note: These figures are rough estimates and may fluctuate due to factors like order volume, supplier pricing strategies, and regional market dynamics.

Part Costs

- Part Size

The physical size of a part directly affects the overall production cost. Large parts not only require more raw material input, but also trigger a series of chain reactions: larger tonnage molding equipment is required, which often consumes more energy and has a longer operating cycle, significantly reducing the output efficiency per unit time. As the size increases, the difficulty of maintaining dimensional accuracy increases exponentially, and high-end equipment such as precision machining centers or five-axis machine tools may be required, which will push up processing costs.

During the injection molding process, the proportion of runner waste generated by large parts is also more considerable, and the recycling and processing of this part of the waste will add an additional cost burden.

- Part Complexity

Complex product design leads to increased costs all around. First, the need to create complex shapes, fine details, or hidden features requires complex molds with special moving parts, which are often more expensive to design and manufacture, directly increasing injection mold cost. In production, high-end machines and very precise settings are often required to make complex parts. Maintaining tight tolerances increases costs and slows things down.

More notably, complex plastic injection molded parts require extended cooling and curing cycle times, which not only reduces equipment utilization but also increases energy consumption. Statistics of plastic injection molding cost show that for every level of complexity increase, the product defect rate may increase by 5-8 percentage points, and the resulting rework and scrap losses cannot be ignored.

- Part Design for Manufacturability

Excellent design for manufacturability can produce significant cost advantages. Intelligent DFM reduces the plastic used in the part itself and allows for simpler runner systems, reducing material costs and waste. By properly controlling the uniformity of wall thickness and geometry, deformation problems caused by uneven cooling can be avoided and production speed can be accelerated.

On the contrary, a design that ignores manufacturability often leads to hidden costs such as repeated mold repairs, production interruptions, high scrap rates and expensive delays, which sometimes exceed 50% of the original mold cost.

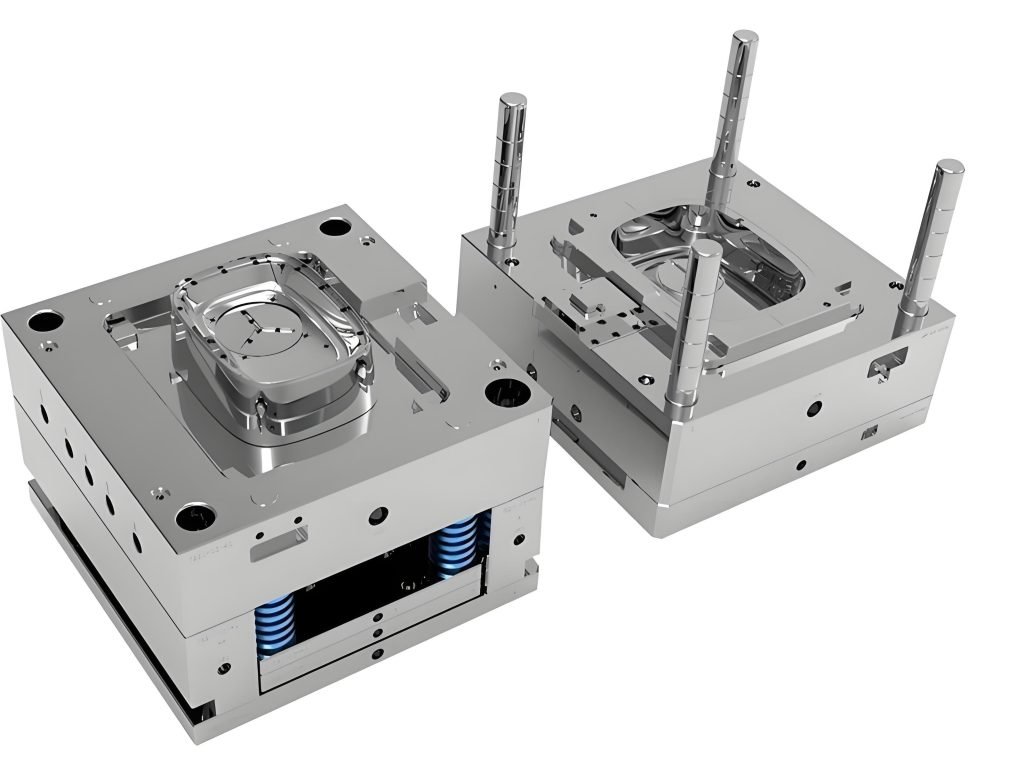

Tooling Costs

Injection molding mold cost depends on the mold’s manufacturing process, material selection, mold design complexity, and cavity size.

- Mold Manufacturing Method

3D Printing: Perfect for rapid prototyping and intricate designs, but material choices and long-term durability are trade-offs. Ideal for low-volume runs, with setup costs typically between $1K and $10K.

CNC Machining: Precision & Material Flexibility, But Consider Waste & Time. Delivers exceptional accuracy and works with diverse materials. Be mindful of higher material waste and longer lead times. Tooling costs start around $5,000, climbing well past $100K for highly complex jobs.

EDM Machining: Proficient in performing ultra-precise and complex machining, but requires the use of conductive materials and custom electrodes, pushing tooling investments from $10,000 into the $1M+ range.

- Mold Material Selection

In the industrial domain, the following two categories of mold materials are commonly adopted:

Steel: Known for its robust durability, it is highly suitable for high-volume manufacturing. Nevertheless, the upfront investment tends to be relatively higher.

Aluminum: Featuring a lightweight design, rust-proof properties, and cost-effectiveness, this material is well-adapted to specific application scenarios.

- Mold Design Complexity & Cavity Size

Molds with undercuts or complex shapes take longer to machine and cost more to make. Simplifying the mold design cuts expenses without sacrificing functionality. Likewise, oversized cavities demand extra material and complicated frameworks – driving up overall injection mold costs. Optimizing cavity dimensions based on actual part dimensions reduces material waste and tooling expenses. Balancing these factors ensures cost-effective mold production while meeting performance and production targets.

Equipment Costs

Molding equipment is unique, with machine costs varying by size and automation level, ranging from $10K for small low-volume setups to $200K for large high-volume machines, with mid-range models over $50K. Key types of injection molding machines that impact costs:

- Hydraulic machines use pumps, offering durability and consistent performance at lower upfront costs but consume more energy and lack precision.

- Electric models employ servo motors, delivering energy efficiency, precision, and low maintenance, though requiring higher initial investment.

- Hybrids machine blend both above two systems, balancing efficiency and precision, but demand intensive maintenance and have steep startup costs.

Many businesses outsource molding to avoid machine purchase costs, instead paying service providers for production.

Production Volume

Production volume impacts material needs, machine selection, and mold durability. Three key categories exist:

- Low Volume Production

Uses simple molds (aluminum/3D-printed), basic machines, and minimal material—lower initial cost but higher per-unit pricing.

- Medium/High Volume Production

Using steel injection molds (which have long lifespans and wide material compatibility) along with complex machinery increases injection molding costs. However, these costs can be spread across parts, reducing the cost per individual component. The cost-sharing ratio is higher for high-volume production compared to medium-volume production, resulting in lower costs per part.

Labor Costs

Labor costs cover expenses for human workers in injection molding. Setting up the machine demands significant time due to the precision needed. Repair costs involve replacing faulty parts and tools during operation. Even though machines are largely automated, operator oversight remains essential and incurs cost.

Others

Surface finishing (like powder coating) and other secondary services (machining, assembly) are separate from injection molding but may get bundled discounts. Note they aren’t always needed, so avoid unnecessary costs and waste. Packaging costs vary: consumer-ready options for final products or protective shipping packaging, with automation reducing errors for large runs. Inspection also varies: standard checks by trained staff are internal, while specialized engineer certification costs more, sometimes offered by the provider. Carefully consider which services you truly require for efficiency.

How to Reduce Injection Molding Costs?

Here are the 5 best tips to reduce injection molding costs while maintaining quality:

Tip 1: Optimize Mold Design

Simplified tool designs cut cycle times, boost productivity, and lower costs by reducing waste and defects. Easy-to-maintain molds last longer, saving on repairs. To streamline designs, remove excess features, refine part shapes, and use standard parts. CAD/CAM tools help trim unnecessary details while maintaining quality.

Tip 2: Simplify Part Features

Streamlining part features simplifies mold construction, reducing production costs since intricate molds are more expensive. Less complex designs also minimize material consumption, lowering expenses directly. Simplified parts often shorten molding cycles, enhancing output while saving on labor and energy costs. These designs typically require less mold maintenance and improve part durability and quality consistency, decreasing defect risks.

To optimize designs, conduct detailed reviews to balance functionality with manufacturability. This may involve reassessing decorative elements, merging components for efficiency, or adjusting dimensions to remove non-essential features. The aim is to harmonize performance needs with economical production.

Tip 3: Optimize Material Choice

High-performance plastics can be costly. Instead, pick materials based purely on the part’s needs to cut costs without losing quality. Assess what your plastic parts face. Battery casings need heat resistance, unlike dashboard knobs which can use cheaper plastic. For instance, maybe acrylic works instead of polycarbonate, or HDPE instead of ABS.

Tip 4: Opt for Multi-Cavity Molds

Smart mold design cuts costs long-term. Opt for multi-cavity molds when producing identical parts – they slash mold changeovers. Single mold often holds 6-8 (or more) small components, trimming production time by 80%. Even differently shaped parts (like model plane kits) can share one mold, increasing output and trimming assembly expenses. For symmetrical components, design mirrored pieces with interlocking features. This clever approach halves tooling costs by using a single mold for paired parts.

Tip 5: Get a Moldability-DFM Analysis

A thorough Moldability-DFM (Design for Manufacturability) analysis is essential for any injection molding project. It pinpoints potential issues like insufficient draft angles, overly complex details, or unfeasible shapes – things best fixed before final approval and production starts. This analysis provides crucial confidence by verifying all production-impacting factors. Carefully review its findings. If you’re unsure, discuss the recommendations with your molding partner during the design phase.

Conclusion

Understanding injection molding costs is key to optimizing the manufacturing process. This can be achieved by grasping the various factors and elements involved, and this article has covered everything you need to know about how much does injection molding cost and how to apply that knowledge.

Looking for a reliable partner for your cost-effective injection molding? Fecision delivers top-tier quality without breaking the bank – we offer exceptional value.

As an ISO-certified team, we equip advanced CNC/EDM gear, and ace both rapid tooling and mass production. Here’s what makes Fecision the go-to choice:

- No minimum orders – perfect for prototypes or scaling

- Free DFM analysis – slash costs before production

- High-quality molds (steel/aluminum) sized for your production volume

- Precision engineering accuracy within ±0.005mm tolerances

Injection molding tooling cost becomes a strategic investment—not a barrier—when every dollar is matched to value. Discover how Fecision balances premium quality with strategic value. Connect with our team today at https://fecision.com for a personalized quote. We welcome the opportunity to partner with you and build intelligently.