The complexity, accuracy, and manufacturing speed of high-end injection molding machines make them vital in producing a wide range of products, from automotive parts to consumer electronics. In this comprehensive guide, we’ll explore the industry leaders and their innovations, providing valuable insights into the evolution of the injection molding industry.

You’ll gain a deeper understanding of the factors that determine the top manufacturers in today’s competitive market and how technological advancements have shaped the current generation of molding machines.

The State of the Injection Molding Machine Industry in 2025

As we step into 2025, the injection molding machine industry is witnessing unprecedented growth. The global market has reached new heights, driven by increased demand across various sectors such as automotive, medical, packaging, and consumer goods.

Market Size and Growth Trends

The injection molding machine industry has seen significant expansion, with regional manufacturing hubs shifting to accommodate growing demands. Asia-Pacific continues to dominate the market, while North American and European markets focus on high-precision and specialized injection molding machines. The global market size has grown substantially, driven by the need for efficient and precise manufacturing solutions.

Technological Advancements Shaping the Industry

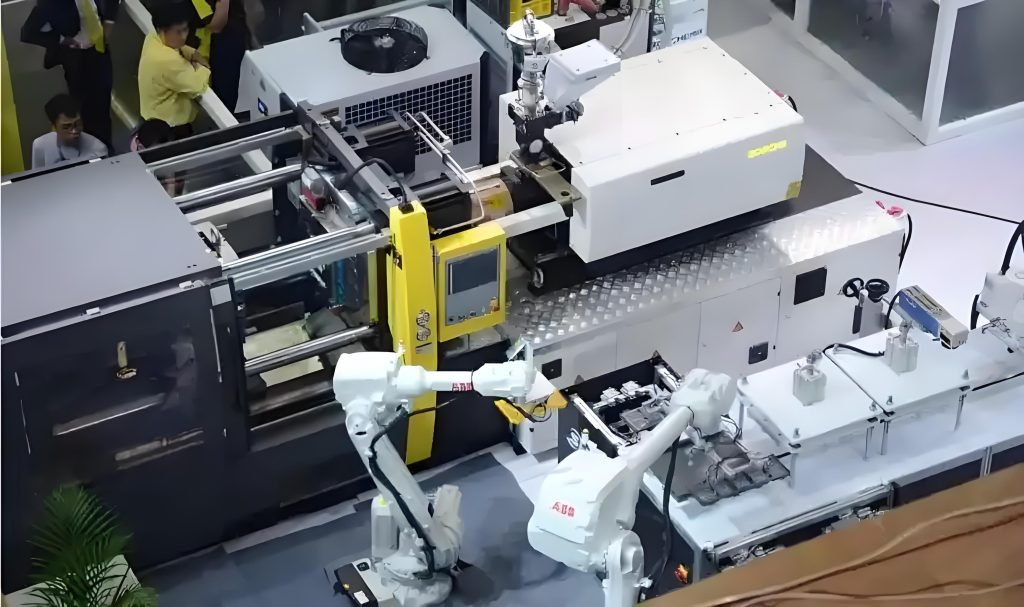

Technological advancements have transformed the injection molding machine industry. AI-powered predictive maintenance, IoT connectivity for real-time monitoring, and advanced automation systems have revolutionized production efficiency. Manufacturers are focusing on energy-efficient designs and compatibility with recycled and bio-based materials, driving sustainability initiatives forward. The industry’s competitive landscape has evolved with strategic mergers and acquisitions, reshaping market share distribution among top manufacturers.

Understanding Injection Molding Machines

Understanding the mechanics and applications of injection molding machines is essential for anyone involved in manufacturing. Injection molding machines play a crucial role in producing a vast array of plastic products that are used across various industries.

What is an Injection Molding Machine?

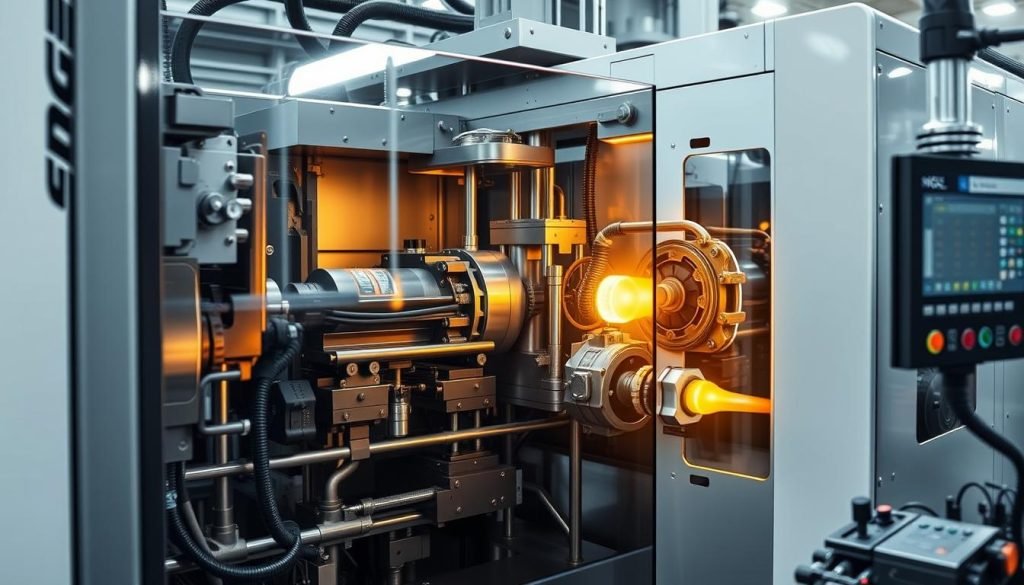

An injection molding machine is a specialized manufacturing equipment designed to produce plastic parts by injecting molten material into a mold where it cools and hardens into the final product shape. This process involves pouring heated, softened resin into a mold, subjecting it to high pressure, and then removing the cooled product.

How Injection Molding Machines Work

The injection molding process follows a precise sequence: plastic pellets are fed into the machine, heated until melted, injected into the mold under pressure, cooled until solidified, and finally ejected as finished parts. The machine consists of two main components: the injection unit, which melts and injects the plastic, and the clamping unit, which holds the mold closed against injection pressure.

Common Applications Across Industries

Injection molding machines serve diverse industries, including automotive, consumer goods, medical, and electronics. They are used to produce a wide range of products, such as dashboards, bumpers, toys, household items, surgical tools, implants, housings, and connectors. The versatility and efficiency of injection molding machines make them a preferred manufacturing method for complex plastic parts.

Types of Injection Molding Machines

As you explore the world of injection molding, you’ll discover several types of machines, each with its unique advantages and applications. The evolution of injection molding machines has led to the development of various technologies, catering to different manufacturing needs and enhancing production efficiency.

Hydraulic Injection Molding Machines

Hydraulic injection molding machines utilize fluid power systems to generate the force needed for plastic injection and mold clamping. They offer robust performance for high-tonnage applications at a lower initial investment cost. Historically, hydraulic presses were the only option available to molders until the introduction of all-electric machines.

Electric Injection Molding Machines

Electric injection molding machines, powered by servo motors, provide superior precision, energy efficiency, and cleaner operation. They offer up to 70% energy savings compared to hydraulic systems, although at a higher purchase price. Electric machines are known for being quieter, faster, and having higher accuracy, making them ideal for applications requiring precision.

Hybrid Injection Molding Machines

Hybrid injection molding machines combine hydraulic and electric technologies, typically using electric drives for precision movements and hydraulic systems for high-force applications like clamping. This combination offers a balance between performance and cost, making hybrid machines suitable for a wide range of applications.

Specialized Injection Molding Machines

Specialized injection molding machines include multi-material machines capable of molding different materials or colors in one cycle, vertical machines ideal for insert molding, and micro-injection machines designed for extremely small precision parts. These machines cater to specific manufacturing requirements, enhancing product complexity and quality.

Understanding the different types of injection molding machines helps you determine which technology best suits your particular manufacturing needs, whether it’s for high-tonnage applications, precision parts, or complex product designs.

Key Technical Parameters of Injection Molding Machines

When selecting an injection molding machine, understanding the key technical parameters is crucial for optimal production. These parameters play a significant role in determining the machine’s performance, efficiency, and product quality.

Clamping Force and Tonnage

The clamping force, measured in tons, is a critical parameter that determines the maximum force an injection molding machine can apply to keep the mold closed during injection. Machines range from small 15-ton units to massive 4,000+ ton systems, allowing for a wide variety of applications.

Shot Size and Injection Capacity

Shot size and injection capacity define the maximum volume of material a machine can inject in a single cycle, directly impacting the size and weight of parts you can produce. For stability, the injection volume should be greater than 1.35 times the weight of the finished product.

Screw Design and Specifications

The screw design and specifications, including diameter, length-to-diameter ratio, and compression ratio, significantly influence material melting quality, mixing effectiveness, and overall part consistency. Some engineering plastics require higher injection pressure and suitable screw compression ratio design for better molding effect.

Energy Efficiency Ratings

Energy efficiency ratings have become increasingly important parameters, with modern machines featuring energy recovery systems, variable-speed pumps, and insulated barrels to reduce power consumption. This not only saves energy but also reduces operational costs.

Understanding these technical parameters and how they interact is essential for achieving optimal production quality and efficiency. Proper matching of these specifications to your specific application requirements is crucial for successful injection molding.

Top 10 Injection Molding Machine Manufacturers in 2025

As we look at the injection molding machine industry in 2025, several top manufacturers stand out. The top 10 plastic injection molding machine manufacturers in the world include ENGEL (Austria), Haitian International (China), Milacron (USA), ARBURG (Germany), Husky (Canada), Sumitomo Demag (Germany), Shibaura (Japan), JSW (Japan), NISSEI (Japan), and FANUC (Japan). These companies have demonstrated exceptional performance in the global market.

Selection Methodology and Criteria

Our selection of the top 10 injection molding machine manufacturers for 2025 is based on a comprehensive evaluation of market share, technological innovation, product reliability, and customer satisfaction across global markets. We analyzed financial performance metrics, including annual revenue, growth rate, and R&D investment, to identify companies demonstrating both current strength and future potential.

The assessment included evaluating each manufacturer’s technological capabilities, global service infrastructure, and commitment to sustainability initiatives. The final rankings reflect a balanced assessment of quantitative performance data and qualitative factors, including industry reputation and adaptability to changing market conditions.

ENGEL (Austria)

You can rely on ENGEL for cutting-edge injection molding solutions that cater to a wide range of industries. ENGEL is a renowned manufacturer of injection molding machines, offering a comprehensive range of products and services.

Company Overview and History

ENGEL, founded in 1945 in Austria, has evolved into a global leader in the injection molding machine industry. With over 7,000 employees and an annual revenue exceeding $1.5 billion, ENGEL is a significant player in the market.

Flagship Products and Innovations

ENGEL’s product portfolio includes all-electric, hydraulic, and hybrid injection molding machines with clamping forces ranging from 280 kN to 55,000 kN. The company’s innovative products, such as tie-bar-less technology and the iQ weight control system, have revolutionized the industry.

Market Position and Strengths

ENGEL’s strong global presence, with production facilities and technical centers across Europe, North America, and Asia, supports its position as a leading manufacturer. The company’s focus on integrated system solutions and comprehensive service network ensures prompt customer support worldwide.

Haitian International (China)

You can explore how Haitian International has become the world’s largest injection molding machine manufacturer by volume, with a rich history dating back to 1966 in Ningbo, China.

Company Overview and History

Haitian International is a leading plastic injection molding machine manufacturer in China, established in 1966. With over 6,600 employees, the company has achieved an annual revenue of $2.5 billion.

Flagship Products and Innovations

Haitian’s flagship product lines include the energy-efficient Mars series (servo-hydraulic machines), the all-electric Zhafir Venus series, and the two-platen Jupiter series. These products cater to various applications, from small precision parts to large automotive components.

Market Position and Strengths

Haitian International has captured significant market share in emerging markets while expanding its presence in developed regions. The company’s competitive pricing, reliable performance, and continuous technological improvement have positioned it as a formidable competitor to traditional European and Japanese injection molding machine manufacturers.

Milacron (USA)

You can rely on Milacron for advanced injection molding solutions, backed by decades of expertise. Milacron is a leading manufacturer of plastic injection molding machines.

Company Overview and History

Milacron, founded in 1874 in Cincinnati, Ohio, has a rich history spanning over 145 years. With 5600 employees and $1.258 billion in revenue, it’s a significant player in the global injection molding machine market.

Flagship Products and Innovations

Milacron offers a comprehensive product portfolio, including the Magna T Servo hydraulic series, all-electric Roboshot and ELEKTRON machines, and innovative Quantum toggle machines. These products are designed for precision and energy efficiency.

Market Position and Strengths

Milacron maintains a strong market position with its global service network spanning 77 countries. The company provides highly customized equipment, components, and services throughout the life cycle of plastics processing technology systems.

ARBURG (Germany)

You’ll find that ARBURG’s commitment to excellence has made it a top choice for injection molding solutions. As a global leader in injection molding technology, ARBURG offers a range of machines.

Company Overview and History

ARBURG, established in 1923 in Lossburg, Germany, remains a family-owned enterprise with a strong commitment to German engineering excellence and manufacturing quality. With 3500 employees and revenue of $578 Million, it’s a significant player.

Flagship Products and Innovations

ARBURG’s flagship ALLROUNDER series of injection molding machines is available in hydraulic, hybrid, and all-electric configurations. The company has pioneered innovations like the SELOGICA control system and the freeformer for industrial additive manufacturing.

Market Position and Strengths

ARBURG maintains a strong focus on technological advancement with approximately 10% of its workforce dedicated to R&D. This ensures continuous improvement in machine performance, energy efficiency, and production quality, making it a preferred manufacturer.

Husky (Canada)

With a rich history since 1953, Husky has established itself as a premier injection molding machine manufacturer. Husky Injection Molding Systems has evolved from a small tool shop to a global leader in injection molding systems and services.

Company Overview and History

Husky is a well-known manufacturer of plastic injection molding machines with over 4,300 employees. Founded in Bolton, Ontario, the company has grown globally with manufacturing facilities in Canada, the United States, Luxembourg, Switzerland, China, and the Czech Republic.

Flagship Products and Innovations

Husky specializes in complete injection molding solutions for the packaging industry, including HyPET systems for PET preforms and HyCAP systems for beverage closures. The company has developed groundbreaking technologies like hot runner systems and multi-layer co-injection technology.

Market Position and Strengths

Husky maintains a dominant market position with its integrated approach, combining machines, molds, and auxiliary equipment as complete manufacturing systems. This makes Husky the preferred partner for high-volume applications in packaging, medical, and consumer electronics industries.

Sumitomo Demag (Germany)

With its roots in Japanese and German engineering, Sumitomo Demag has established itself as a premier manufacturer of injection molding machines. The company represents a powerful merger between Sumitomo Heavy Industries and Demag, creating a global powerhouse.

Company Overview and History

Sumitomo Demag is part of a global group dedicated to helping plastics processors compete effectively. Established through the merger of Sumitomo Heavy Industries and Demag, the company has a rich history and a strong global presence with production facilities in Japan, Germany, and China.

Flagship Products and Innovations

Sumitomo Demag offers a comprehensive range of injection molding machines, including the IntElect all-electric series, Systec Servo hydraulic series, and El-Exis SP high-speed machines. The company has pioneered innovations like activeFlowBalance technology and the advanced NC5 control system.

Market Position and Strengths

Sumitomo Demag is one of the world’s largest manufacturers of injection molding machines, producing over 5,000 units annually. The company’s global manufacturing footprint and extensive service network support its customers across various industries, including automotive, medical, and packaging.

Shibaura (Japan)

Company Overview and History

Shibaura Machine, formerly Toshiba Machine until 2020, has a rich history dating back to 1875 in Tokyo, Japan, making it one of the oldest manufacturers in the injection molding industry with over 145 years of engineering heritage.

Flagship Products and Innovations

Shibaura offers a comprehensive product lineup, including the all-electric SXIII series known for precision and energy efficiency, hydraulic machines for heavy-duty applications, and specialized machines for multi-material molding. Their V70 controller and advanced servo-drive systems optimize energy consumption.

Market Position and Strengths

Shibaura maintains a global presence with manufacturing facilities in Japan and China, and technical centers and service locations throughout Asia, North America, and Europe. Their focus on continuous technological development has established them as a preferred supplier for high-precision applications.

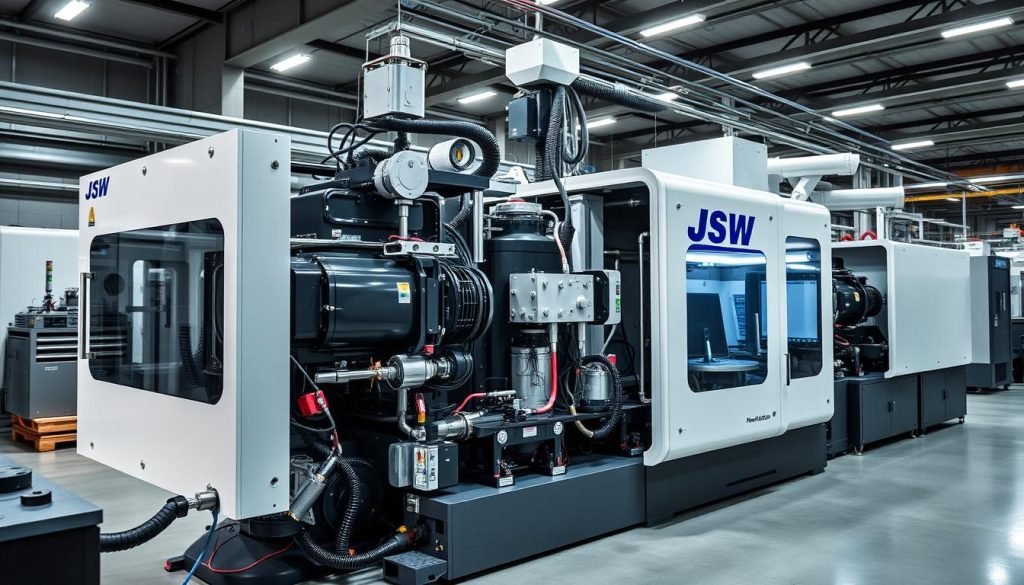

JSW (Japan)

With a rich history dating back to 1907, JSW has evolved into a global leader in injection molding technology. JSW is a leading plastic injection molding machine manufacturer with extensive experience in manufacturing large electric injection molding machines.

Company Overview and History

JSW, established in 1907, has transitioned from steel manufacturing to become a renowned injection molding machine manufacturer. With over 5800 employees and $1.8 Billion in revenue, JSW has a strong global presence.

Flagship Products and Innovations

JSW’s product range includes the J-ADS series of all-electric machines, featuring clamping forces up to 3,000 tons. Innovations include the SYSCOM control system and energy-regenerative drive systems, enhancing productivity and reducing power consumption.

Market Position and Strengths

JSW is a preferred supplier for automotive, consumer appliances, and industrial applications due to its expertise in large electric injection molding machines. Its global manufacturing facilities and service centers provide comprehensive support worldwide.

NISSEI (Japan)

As a pioneering force in injection molding technology, NISSEI Plastic Industrial Co., Ltd. has been at the forefront since its inception in 1947.

Company Overview and History

NISSEI is a leading manufacturer of injection molding machines, founded in Nagano, Japan. With a focus on “professional, profound and extensive” technology, it has expanded its industry scope and improved machine performance.

Flagship Products and Innovations

NISSEI’s product portfolio includes the NEX series all-electric machines, DCX hybrid series, and vertical machines for insert molding. Innovations include N-PlastControl, X-Pump system, and specialized barrel designs.

Market Position and Strengths

NISSEI maintains a global manufacturing presence and is a preferred supplier for high-precision applications in medical, electronics, and automotive industries due to its focus on technological advancement.

FANUC (Japan)

As a global leader in factory automation, FANUC’s injection molding machines represent a significant segment of their comprehensive industrial automation portfolio.

Company Overview and History

FANUC Corporation, established in 1972 as a spin-off from Fujitsu, has grown to become a global leader in factory automation. With over 8,200 employees, FANUC has a strong presence in the industry.

Flagship Products and Innovations

FANUC’s ROBOSHOT series of all-electric injection molding machines is renowned for its exceptional precision, repeatability, and integration capabilities with FANUC’s own robotics and CNC systems.

Market Position and Strengths

FANUC leverages its expertise in servo motors, controls, and robotics to create injection molding systems with industry-leading precision and energy efficiency. The company maintains a massive global presence with manufacturing facilities in Japan and service centers in over 100 countries.

Factors to Consider When Choosing an Injection Molding Machine Manufacturer

Choosing the ideal injection molding machine manufacturer requires careful consideration of several key factors that will impact your production efficiency and product quality.

Technical Capabilities and Machine Specifications

You should evaluate the technical capabilities of the injection molding machine manufacturer, including machine precision specifications and control system sophistication. The manufacturer’s ability to provide machines optimized for your specific application requirements is crucial. This includes assessing the range of injection molding machines available and their compatibility with your production needs.

After-Sales Service and Support

Assessing the manufacturer’s after-sales service infrastructure is vital. This includes evaluating local technical support availability, spare parts inventory, response time guarantees, and preventive maintenance programs. A comprehensive after-sales service will directly impact your production uptime and overall equipment effectiveness.

Price vs. Quality Considerations

The price versus quality equation requires careful consideration. While the initial purchase price is important, the total cost of ownership, including energy consumption, maintenance requirements, and production efficiency, will determine the true value of your investment in an injection molding machine.

Industry Reputation and Customer Reviews

A manufacturer’s industry reputation, customer testimonials, and installed base in your specific industry sector can provide valuable insights into reliability, performance, and long-term satisfaction with their injection molding machines. You should research these aspects to ensure you’re partnering with a reputable manufacturer.

Conclusion

Choosing the right injection molding machine manufacturer is a critical decision for companies relying on plastic injection molding. The global injection molding machine industry in 2025 is marked by technological innovation, with top manufacturers developing more efficient, precise, and sustainable solutions.

The top 10 manufacturers, spanning Europe, Asia, and North America, bring unique strengths to the market. When selecting a manufacturer, consider not just the initial purchase price but the total value proposition, including technical capabilities, service support, and energy efficiency.

As sustainability becomes increasingly important, look for manufacturers investing in energy-efficient designs and production processes that minimize environmental impact. By doing so, you’ll be well-equipped to make an informed decision that meets your business needs and stays ahead in the competitive plastic injection molding market.