5-axis CNC machining cuts production time and labor by 30-40% for low volume manufacturing. This advanced manufacturing technology continues to evolve. 5-axis CNC machines can produce complex parts faster, and reduce overhead and errors than 3-axis machines. The ability to machine more sides of a job in one setup adds quality to your parts and reduces setup times.

If you’re in aerospace, automotive, medical devices or energy industries you rely on 5-axis machining for machining complex, tight tolerance parts. These machines create complex geometries that conventional machining methods cannot achieve. The following content will take you further to understand 5-Axis CNC machines.

What Is a 5-Axis CNC Machine?

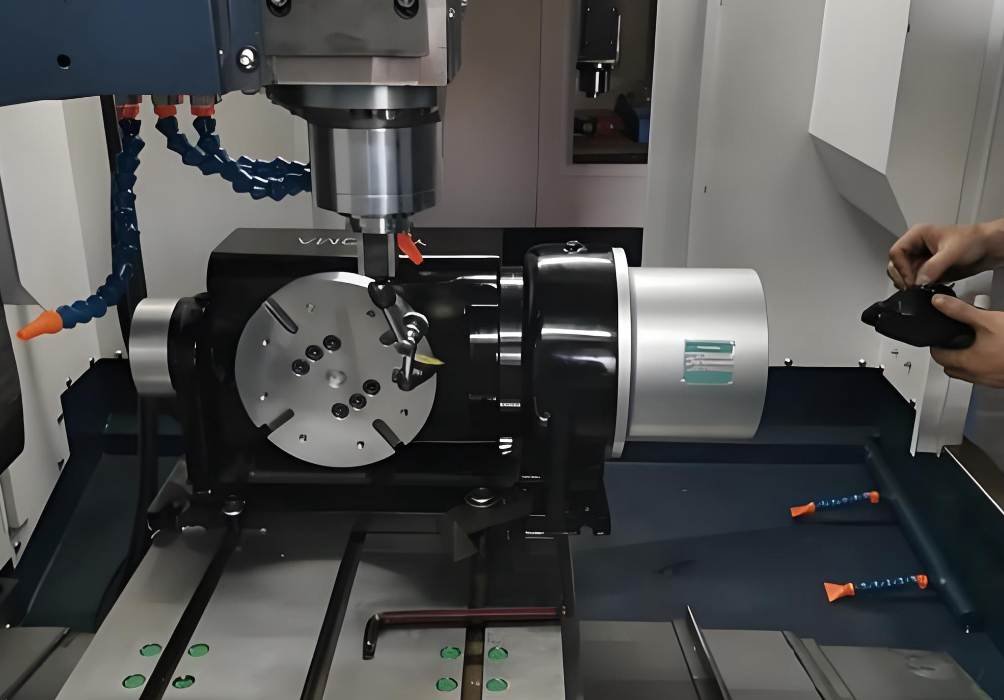

A 5-axis CNC machine describes a sophisticated process in which cutting tools are moved on five axes. This multi-axis subtractive manufacturing process controls the material with 3 linear axes (X, Y, Z) and 2 rotational axes (A, B).

The X-axis controls the machine’s horizontal movement. The Y-axis addresses horizontal movement perpendicular to this, and the Z-axis addresses movement in the Z-plane. The A-axis rotates around the X-axis and the B-axis rotates around the Y-axis.

What Is the Meaning of the ‘5’ in the Term ‘5-Axis’

The ‘5’ in 5-axis machining indicates the means by which such machinery operates outside of traditional 3-axis configurations. Where traditional machinery operates with the use of the X, Y, and Z axes, the A and B rotational axes enable your tool to approach your pieces from every angle. This gives the access to five sides of a piece without repositioning.

Imagine holding something from its bottom with a pen extending straight down from above. If you tilt the thing to the left, the right, the front, and the back (A and B axes), you can move the pen up, down, from side to side, and in and out (X, Y, and Z axes) all simultaneously. This real-world analogy describes how 5-axis machinery can achieve such fantastic accuracy and versatility.

Over the years, these machines have become standard equipment for precision manufacturing. They offer capabilities that match or surpass traditional vertical and horizontal machining centers. Operators can create intricate designs with organic surfaces and complex geometries with complete control over all five axes.

How Does a 5-Axis CNC Machine Work for You?

5-axis CNC machine starts its work with digital design files from CAD software. These designs are translated into CAM software, which creates machine instructions in G-code format, giving exact directions on how tools should move and which cutting tools to use.

The machine’s controller coordinates each axis movement. It adjusts tool positions and orientations immediately to match programmed tool paths with precision. Each axis runs on high-precision servo motors, while feedback systems constantly send position data to keep everything accurate.

Here’s what machining process looks like:

- Create and optimize a CAD model

- Convert it into G-code using CAM software

- Upload the G-code to your machine controller

- Automatically select and position the right tools

- Execute synchronized axis movements

- Monitor feedback continuously

The cutting tool stays in perfect contact with the workpiece’s surface, leading to faster cycle times and better material removal rates. Because the machine controls all five axes at once, it can reach complex features, undercuts, and deep pockets without requiring multiple setups.

The machine’s control system ensures that linear movements (X, Y, Z) work together with rotational motions (A and B axes). This synchronization helps to create complex geometries through precise tool positioning and orientation changes. The system also evaluates tool geometry, cutting speeds, and material removal rates to optimize the machining process.

What Types of 5-Axis CNC Machines Should Be Considered?

The choice of 5-axis machining will be determined where the rotational axes are. Every configuration has its benefits for varying needs.

Rotary Table and Pivoting Spindle Head

This setup has a 360-degree rotating table and a rotating head. This design will be useful for working on cylinder pieces and on pieces with a significant height. The table can be kept static and still process heavy pieces with accuracy.

Double Rotary Table

This setup features a primary rotary table with an additional rotary axis on top. It’s perfect for applications requiring long tools or extensions, offering extended XYZ movement for working at unusual angles.

Trunnion Table Machine

If better undercut capabilities are needed, this configuration is ideal. It places both rotary axes into the table while keeping a stationary machining head. With improved Z-axis clearance, manufacturers gain better flexibility in machining complex parts.

Swivel or Articulating Head

This design keeps the table stationary while the head handles all rotational movements. If manufacturers work with heavier materials, they’ll benefit from the direct weight transfer from the machine base to the ground. Shorter tools improve precision since all rotations occur above the material.

What Benefits Does 5-Axis CNC Machining Offer?

With 5-axis CNC machining, you gain several key advantages:

- Reduced Set-up Time – One setup now does multiple operations, cutting production time by up to 50%. Manufacturers can save money by eliminating expensive jigs and fixtures, and the machine reduces alignment errors by working on five sides without repositioning.

- Complex Design Capabilities—Better tool positioning allows for intricate geometries. This technology is great for organic shapes and detailed features without special tooling.

- Superior Rotational Accuracy – With precise rotary axis control, your parts stay accurate, reducing rejection rates and tight tolerances.

- Faster Material Removal – Optimized cutting paths and tool angles allow to remove more material. The tools last longer and run at higher speeds with less vibration and breakage.

- Better Surface Finishes—The machine maintains tool-to-workpiece contact all the time, reducing the need for additional finishing work and creating smoother surfaces.

How Does 5-Axis CNC Machining Apply to Your Industry?

5-axis CNC machining can be used in many industries to create complex and precise components. In aerospace you can use this technology to make lightweight yet strong engine parts, turbine blades and structural components. By machining from multiple angles you get high precision and reduced material waste.

You can also benefit from 5-axis CNC machining for engine components, transmission systems and drivetrain parts in the automotive industry. The machines can work from different angles to complete complex designs in fewer steps, reducing set-up time. You can get lightweight parts like suspension arms and brackets from aluminum and carbon fiber.

If you are in the medical field and need parts like precise surgical instruments, implants and prosthetics, 5-axis CNC machining can approach parts from any direction. It allows to make intricate medical devices that traditional machines can’t.

When making molds, manufacturers can use 5-axis CNC machining to create complex structures. This process helps to increase productivity and reduce maintenance time. This technology can also be used in the precision machinery and electronics industry, where high-precision parts like sensors and instrument components are needed.

Which Manufacturers Lead in 5-Axis CNC Technology?

Several top manufacturers lead the 5-axis CNC market with these features:

- DMG MORI: Known for precision manufacturing with positioning accuracies within ±0.004mm.

- Haas Automation: Provides affordable yet high-quality 5-axis solutions.

- Mazak: Their VARIAXIS series offers high-speed machining and thermal compensation systems.

- Okuma: Their MU series delivers rigid construction and excellent surface finishes.

- HURCO: Known for conversational control systems, simplifying complex programming.

- Hermle: Their mineral-cast beds enhance stability and vibration dampening.

Conclusion

5-axis CNC machining transforms the industry with the capacity for producing complex pieces with accuracy, speed, and efficacy. Production time and errors can be reduced, and you can even take on complex designs beyond the capacity of traditional 3-axis machines. If you are in the industries like aerospace, automotive, medical, or mold production, this technology provides maximum output and quality.

At Fecision, our advanced 5-axis CNC machining services are designed to handle intricate geometries and demanding specifications with expert precision. Get in touch today to discover how our 5-axis capabilities can bring your most complex designs to life efficiently and reliably.