Can the type of crankshaft in your engine really impact its performance? The answer lies in understanding the role this crucial component plays in your vehicle’s operation. The crankshaft is the backbone of an internal combustion engine, responsible for converting the up-and-down motion of the pistons into rotational energy that powers your vehicle.

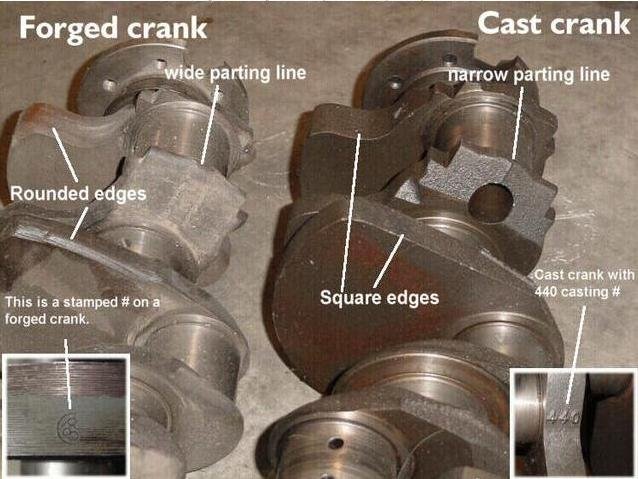

Choosing the right crankshaft is vital for optimal engine performance and longevity. Two primary types dominate the market: those made through casting and those forged from metal. Each has its strengths and is suited for different applications. As we explore the differences between these two types, you’ll gain insight into which one is best suited for your specific engine needs.

Cast Crankshaft: An Overview

Cast crankshafts have been a staple in the automotive industry for decades, offering a reliable and cost-effective solution. You can rely on cast cranks for their adequate performance in standard applications.

Manufacturing Process

The manufacturing process for cast crankshafts involves pouring molten metal, typically cast iron, into precision molds to create the basic crankshaft shape. This process offers significant cost advantages due to less expensive tooling and reduced machining requirements compared to forged alternatives.

The result is a crankshaft that meets the required specifications without excessive material waste or machining time, making it a cost-effective option for many engine applications.

Materials Used

Modern cast crankshafts are available in various materials, including traditional cast iron and newer cast steel options that offer improved strength characteristics. Cast iron crankshafts benefit from a natural work-hardening process during machining that increases the hardness of the journal surfaces.

The use of cast iron or nodular iron for cast cranks provides tensile strength ratings starting around 60,000 psi, making them suitable for many street applications.

Advantages

The primary advantages of cast crankshafts include their lower initial cost, adequate strength for many applications, and good availability for common engine configurations. Cast crankshafts are perfectly suitable for mild to moderate performance builds that don’t subject the engine to extreme stress or shock loads.

Forged Crankshaft: An Overview

Forged crankshafts have become a staple in high-performance engine builds due to their exceptional strength and durability. You might be wondering what makes them so special. The answer lies in their manufacturing process and the materials used.

The Forging Process Explained

The forging process involves compressing heated steel between precision dies under extreme pressure, aligning the metal’s grain structure and creating a significantly stronger component. This process is fundamentally different from casting and results in a crankshaft that can withstand higher stresses and loads.

Materials and Heat Treatment in Forged Crankshafts

Forged cranks are typically made from various steel alloys, including plain carbon steel, 5140 chromium, 4130 molybdenum, and 4340 nickel chromium alloy. After machining, they undergo additional heat treatment processes such as induction hardening, tuftriding, and nitriding to achieve optimal hardness and durability.

Advantages of Forged Crankshafts

The advantages of forged crankshafts include their high tensile strength, which can reach up to 125,000 psi, and superior elongation properties, providing better resistance to sudden shock loads. These characteristics make forged crankshafts ideal for high-horsepower applications and reduce the likelihood of catastrophic failure.

Forged vs Cast Crankshaft: A Detailed Comparison

Cast and forged crankshafts have distinct characteristics that make them suitable for different applications and performance needs. Understanding these differences is crucial for selecting the right crankshaft for your engine build.

Strength and Durability Differences

The fundamental strength difference between cast and forged crankshafts becomes most apparent under high-stress conditions. Forged cranks offer significantly better resistance to fatigue and sudden shock loads compared to their cast counterparts. This makes forged crankshafts more suitable for high-performance applications where engine stress is a significant concern.

Cost and Manufacturing Lead Time

Cost considerations heavily favor cast crankshafts, which typically cost 30-50% less than comparable forged options. This makes cast crankshafts an attractive choice for budget-conscious builds with moderate performance goals. However, manufacturing lead time is generally shorter for cast crankshafts, while forged cranks, especially custom or specialized versions, may require longer production times due to more complex manufacturing and heat treatment processes.

Performance in High-Stress Applications

High-stress applications such as forced induction, nitrous oxide injection, or high-RPM racing environments strongly favor forged crankshafts for their superior strength and shock resistance. Engines using power adders like superchargers benefit from forged cranks, as cast versions are prone to snout failures when driving larger superchargers.

Weight and Balance Considerations

Weight and balance characteristics differ between the two types, with premium forged cranks often offering better options for weight reduction and precision balancing for high-performance applications. This is particularly important in racing environments where every ounce counts and optimal balance is crucial for performance.

Ideal Applications for Each Type

Street performance engines making up to 500 horsepower with automatic transmissions can often reliably use quality cast crankshafts. In contrast, manual transmission applications benefit from forged cranks due to the additional shock loads from clutch engagement. Racing applications, particularly those involving frequent high-RPM operation or sudden load changes, strongly favor forged crankshafts despite their higher cost.

In conclusion, the choice between a cast and forged crankshaft depends on your specific engine requirements, performance goals, and budget. While cast crankshafts offer cost-effectiveness and are suitable for many street performance applications, forged crankshafts provide the strength and durability needed for high-stress and high-performance environments.

Custom Cast & Forged Crankshafts Made by Fecision

For engine builders needing high-performance crankshafts, Fecision’s custom services stand out. We offer manufacturing services for both custom cast and forged crankshafts tailored to specific engine applications.

Our manufacturing process incorporates advanced metallurgical techniques to produce crankshafts with optimal grain structure and strength characteristics. Our cast crankshafts utilize premium iron and steel alloys, providing enhanced durability for performance applications at competitive price points.

For high-performance applications, Fecision offers forged crankshafts in various steel alloys, including 4340 chromoly, providing exceptional strength-to-weight ratios and resistance to fatigue. Custom stroke lengths are available for both cast and forged crankshafts, allowing engine builders to achieve desired displacement increases without compromising reliability.

Let’s cooperate with Fecision for the success of your crankshaft projects!