Did you know that vertical milling machines are among the most versatile equipments for manufacturing operations, with applications ranging from automotive parts to aerospace components? A vertical mill is a precision cutting tool that removes material from workpieces through rotary cutters, distinguished by its vertically aligned spindle axis.

Understanding the different configurations of milling machines is crucial for optimizing production capabilities and operating costs. This comprehensive guide will walk you through the basics of vertical milling machines, their features, and applications, helping you make informed decisions about CNC milling technology.

What Are Vertical Milling Machines

A vertical milling machine is defined by its vertically oriented spindle axis, which enables it to perform a variety of machining tasks with high precision. The basic concept revolves around the machine’s ability to remove material from a workpiece using rotating cutting tools. This is achieved through a combination of movements along the X, Y, and Z axes, allowing for complex geometries to be machined.

The transition from manual to automated systems, and later to computer numerical control (CNC) technology, has revolutionized vertical milling. Today, these machines combine historical principles with cutting-edge technology, offering unprecedented precision, speed, and versatility in manufacturing.

How Vertical Milling Machines Work

To get the most out of your CNC milling projects, it’s essential to understand the working principles of vertical milling machines.

Core Operating Principles

Vertical milling machines operate with the spindle axis perpendicular to the worktable. This orientation allows for excellent visibility of the cutting operation, making it more intuitive for operators. The machines are capable of performing facing, pocketing, profiling, and drilling operations with ease.

The core operating principle revolves around the movement of the spindle and the worktable. The spindle holds the cutting tool and rotates at high speeds, while the worktable moves in multiple axes to acilitate complex machining operations.

Difference Between Vertical and Horizontal Milling

The primary difference between vertical and horizontal milling lies in the spindle orientation. Vertical mills have the spindle perpendicular to the worktable, while horizontal mills have it parallel. This difference significantly affects the type of operations each can perform efficiently.

Vertical milling machines are ideal for detailed work on a single face and are more versatile for one-off projects. In contrast, horizontal mills excel at heavy material removal and are better suited for production runs.

Key Components of Vertical Mills

Vertical mills are complex devices made up of several critical parts that work together to achieve precise machining results.

Spindle Assembly and Motor System

The spindle assembly and motor system are vital components of a vertical mill. The spindle assembly houses the cutting tool and rotates at high speeds, while the motor system provides the power needed to drive the spindle.

A robust spindle assembly ensures precise control over the cutting tool, allowing for accurate machining operations.

Work Table and Axis Movement

The work table and axis movement system enable the precise positioning of the workpiece. The work table provides a stable surface for the workpiece, while the axis movement system allows for movement along the X, Y, and Z axes.

Column and Structural Elements

The column and other structural elements provide the framework that supports the various components of the vertical mill. A sturdy column ensures the stability and rigidity needed for precise machining.

Control Systems

Control systems for vertical mills range from manual to sophisticated CNC systems. Modern CNC control systems offer fully programmable operation, allowing for complex machining operations with minimal operator intervention.

These systems often include features like conversational programming and simulation capabilities, enhancing the efficiency and accuracy of the machining process.

Types of Vertical Mills

Vertical mills come in various configurations to suit different machining needs. The choice of a vertical mill depends on the specific requirements of the project, including the type of material being machined, the complexity of the operation, and the desired level of precision.

Manual Vertical Mills

Manual vertical mills are operated by hand, offering a high degree of control over the machining process. They are ideal for small-scale or custom projects where precision is crucial.

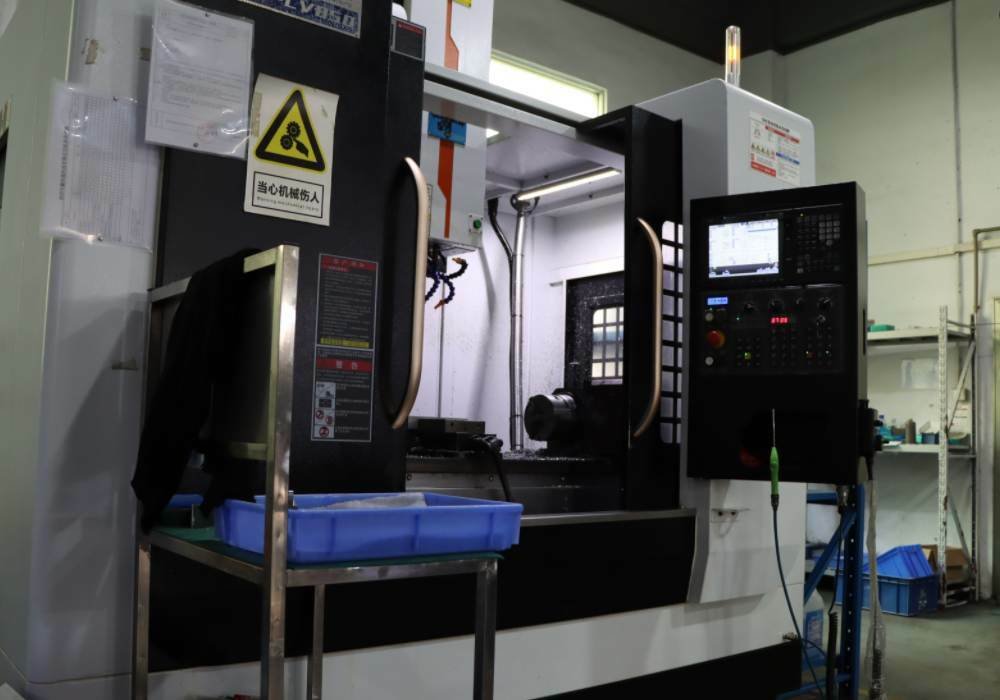

CNC Vertical Machining Centers (VMCs)

CNC VMCs are automated machines that use computer programs to control the machining process. They offer high precision and efficiency, making them suitable for large-scale production runs.

Bed-Type Vertical Mills

Bed-type vertical mills feature a fixed bed and are designed for heavy-duty machining operations. They are often used in industries that require high precision and reliability.

Turret Vertical Mills

Turret vertical mills, also known as “Bridgeport-style” mills, are versatile machines that feature a turret head capable of rotating and swiveling. They are ideal for both custom work and small production runs.

Main Features of Vertical CNC Milling Machines

Vertical CNC milling machines are equipped with advanced features that enhance their performance and versatility in various manufacturing operations. These machines are designed to provide high precision and accuracy, making them ideal for complex machining tasks.

Precision and Accuracy Capabilities

Vertical CNC milling machines offer exceptional precision and accuracy capabilities, thanks to their advanced CNC control systems and high-quality construction. This precision enables the production of intricate parts with tight tolerances, which is crucial in industries such as aerospace and automotive. The machines’ accuracy is further enhanced by advanced features like adaptive control technologies.

Speed and Power Specifications

The speed and power specifications of vertical CNC milling machines vary widely, depending on the specific model and application. These machines can range from compact, high-speed milling centers to large, heavy-duty machines capable of handling demanding tasks. The spindle speed and power are critical factors that determine the machine’s ability to handle different materials and machining operations.

Tool Changing Systems

One of the key features of vertical CNC milling machines is their tool changing systems, which enable rapid and automatic tool changes. This capability significantly reduces downtime and increases productivity, as operators can preset multiple tools and switch between them quickly. Modern tool changers can handle a wide range of tools, from simple drills to complex milling cutters.

Control Software and Programming

The control software and programming capabilities of vertical CNC milling machines are crucial for their operation. Modern CNC control systems offer sophisticated programming capabilities, including G-code programming and conversational interfaces, which simplify complex machining operations. Advanced simulation features allow operators to verify toolpaths virtually before cutting material, reducing the risk of crashes and optimizing cutting strategies.

Additionally, networking capabilities enable direct transfer of programs from CAD/CAM systems to the machine control, streamlining workflow and reducing programming errors. The integration of Industry 4.0 features allows vertical CNC mills to communicate with other manufacturing systems, providing data for production monitoring, predictive maintenance, and quality control.

Applications of Vertical Mills Across Industries

Vertical CNC milling machines play a crucial role in various sectors. Their versatility and precision make them an essential tool across different industries.

Automotive and Aerospace Manufacturing

In the automotive and aerospace industries, vertical mills are used for producing complex parts with high precision. They are capable of machining a variety of materials, including aluminum, steel, and titanium, which are commonly used in these sectors.

General Manufacturing and Toolmaking

General manufacturing and toolmaking industries rely on vertical mills for producing molds, dies, and other precision tools. The ability to work with diverse materials, such as hardened steels and plastics, makes them invaluable in these applications.

Medical and Electronics Industries

The medical and electronics industries benefit from the precision and versatility of vertical mills. They are used to manufacture components for medical devices and electronic equipment, where accuracy and reliability are paramount.

How to Match Suitable Vertical Mills

To maximize productivity and efficiency, it’s essential to select the right vertical mill for the specific needs. The process involves several key considerations that can significantly impact your machining operations.

Assessing Production Requirements

Begin by evaluating production needs, including the types of materials to work with, the complexity of the projects, and production volume. This assessment will help to determine the capabilities and features required in a vertical mill.

Budget Considerations

Consider the project budget. Vertical mills vary significantly in operation cost, so it’s crucial to balance needs with the practical constraint.

Evaluating Technical Specifications

Examine the technical specifications of vertical mills, including spindle speed, axis travel, and the type of control system. These specifications will directly affect the machine’s performance and its ability to meet the production requirements.

Choose Fecision for Your CNC Milling Projects

As we’ve explored, vertical milling machines offer unparalleled versatility and precision. Understanding the different types of vertical mills and their applications is crucial for making informed decisions about the manufacturing needs.

Fecision offers expert CNC milling service tailored to your manufacturing needs. Our experienced team of machinists and engineers specializes in vertical milling operations across a wide range of materials.

With our advanced vertical CNC milling centers, we can produce complex parts with tight tolerances, ensuring consistent quality whether you need prototype parts or full production runs. Fecision’s commitment to quality is evident in our rigorous inspection processes.

Our competitive pricing, quick turnaround times, and dedication to customer satisfaction make Fecision the ideal partner for all your CNC milling projects. Contact Fecision today to discuss your vertical milling needs and discover how our expertise can help bring your projects to life with precision and efficiency.