In extreme environments where high temperatures and pressures are a norm, a special kind of alloy stands out for its exceptional performance – Inconel 718. This nickel-chromium-based superalloy is renowned for its ability to maintain strength and resist corrosion, making it a critical material in various high-tech industries.

You might be wondering what makes Inconel 718 so unique. Its impressive properties, including resistance to oxidation and corrosion, along with its ability to retain strength over a wide temperature range, make it an ideal choice for high-temperature applications.

As we explore the composition, properties, and uses of this remarkable alloy, you’ll gain a deeper understanding of why Inconel 718 is preferred in demanding industries.

What is Inconel 718?

Inconel 718 is a high-strength, corrosion-resistant alloy that has become a staple in various industries, including aerospace, oil and gas, and power generation.

History and Development

Inconel 718 has a rich history that dates back to the 1960s when it was first developed by International Nickel Company (INCO). The alloy was created to address the need for a high-temperature, high-strength material that could withstand the harsh conditions found in jet engines and other high-performance applications. Over the years, Inconel 718 has undergone significant improvements, with advancements in production techniques and alloy composition.

Classification as a Superalloy

Inconel 718 is classified as a superalloy due to its exceptional ability to maintain mechanical strength, surface stability, and corrosion resistance at temperatures far beyond what conventional alloys can withstand. The classification of Inconel 718 as a nickel-based superalloy relates to its primary element (nickel), which provides the stable face-centered cubic crystal structure that contributes to its remarkable properties.

Understanding Inconel 718’s place in the superalloy family helps you appreciate why it’s selected for critical applications where failure is not an option, such as in aerospace components and nuclear reactors. Superalloys like Inconel 718 are distinguished by their ability to operate in the most demanding environments, such as the hot sections of gas turbines where temperatures can exceed 1000°F (538°C).

Chemical Composition of Inconel 718

To grasp the properties of Inconel 718, it’s essential to examine its chemical composition closely. The alloy’s performance is directly related to its chemical makeup, which is carefully controlled to achieve the desired mechanical properties and resistance to corrosion.

Primary Elements

Inconel 718 is primarily composed of nickel, chromium, and iron, with significant additions of niobium, molybdenum, and titanium. The nickel content provides the alloy with its excellent corrosion resistance and high-temperature strength. Chromium further enhances the oxidation resistance, while iron contributes to the alloy’s overall strength and durability.

The presence of niobium is crucial for the precipitation hardening process, which significantly enhances the alloy’s strength. Molybdenum and titanium also play important roles in improving the mechanical properties and resistance to corrosion.

Secondary Elements and Their Functions

In addition to the primary elements, Inconel 718 contains several secondary elements that are crucial for its performance. These include aluminum, carbon, and manganese, among others. Aluminum, for instance, helps in the formation of the gamma prime phase, which is vital for the alloy’s high-temperature strength.

These secondary elements, though present in smaller quantities, are essential for fine-tuning the alloy’s properties and ensuring it meets the required specifications.

Composition Specifications and Standards

The composition of Inconel 718 is governed by strict specifications and standards, such as AMS5662, AMS5663, ASTM B637, and UNS N07718. These standards define the acceptable ranges for each element, ensuring consistency and reliability across different manufacturers and production batches.

Adhering to these specifications is crucial for manufacturers to ensure that the Inconel 718 they produce will perform as expected in critical applications. Familiarity with these composition specifications and standards is essential for engineers and procurement specialists when sourcing Inconel 718 for specific applications.

Thermal Properties of Inconel 718

Understanding the thermal properties of Inconel 718 is essential for engineers and designers working with high-temperature systems. These properties dictate how the material behaves under various temperature conditions, influencing its suitability for specific applications.

Thermal Conductivity

Inconel 718 has a relatively low thermal conductivity compared to other metals. This characteristic affects its ability to dissipate heat, making it crucial to consider in designs where heat transfer is a significant factor. The thermal conductivity of Inconel 718 is an important consideration in applications such as gas turbines and heat exchangers.

Melting Point and Temperature Range

The melting point of Inconel 718 is approximately 1260°C to 1336°C, indicating its high-temperature stability. This range is critical for understanding the material’s behavior in extreme environments. The temperature range over which Inconel 718 maintains its properties is a key factor in its selection for aerospace and industrial gas turbine components.

Coefficient of Thermal Expansion

Inconel 718 exhibits a coefficient of thermal expansion of approximately 12.1 × 10^-6 m/m/°C in the temperature range of 20-100°C. This relatively low thermal expansion is beneficial in applications requiring dimensional stability, such as precision components for aerospace and gas turbines. As temperature increases, the coefficient of thermal expansion rises, reaching about 16 × 10^-6 m/m/°C at 800°C. This increase must be considered in high-temperature design applications to ensure compatibility with other materials and to minimize thermal stresses.

The controlled thermal expansion of Inconel 718 makes it compatible with other materials in complex assemblies, reducing the risk of premature failure due to thermal stresses. Understanding this property is crucial for engineers designing components that will experience temperature fluctuations.

Physical Properties of Inconel 718

Understanding the physical properties of Inconel 718 is essential for engineers and designers working with this superalloy. You need to consider its density, electrical characteristics, and magnetic behavior to optimize its performance in various applications.

Density and Weight

Inconel 718 has a density of approximately 8.2 g/cm³, which is relatively high compared to some other alloys. This density contributes to its strength and durability, making it suitable for demanding applications. You should consider this property when designing components that require a certain weight or mass.

Electrical Properties

Inconel 718 exhibits moderate electrical resistivity, which can be beneficial in certain applications where high electrical conductivity is not required. Its electrical properties remain relatively stable over a range of temperatures, making it suitable for use in electrical components. You can rely on Inconel 718 for applications that require resistance to electrical current.

Magnetic Properties

Inconel 718 is essentially non-magnetic in its annealed condition, with a relative magnetic permeability of less than 1.002 at room temperature. This property makes it ideal for applications where magnetic interference must be minimized. You should note that cold working or certain heat treatments can slightly increase its magnetic permeability, though it generally remains non-magnetic for most practical purposes.

Mechanical Properties of Inconel 718

Inconel 718’s mechanical properties are crucial for its application in high-stress environments. The alloy’s performance under various loading conditions is a key factor in its widespread use.

Tensile Strength and Hardness

Inconel 718 boasts high tensile strength and hardness, attributes that are essential for its use in demanding applications. The alloy’s tensile strength is significantly enhanced through precipitation hardening, a process that contributes to its high yield strength and resistance to deformation.

Fatigue Resistance

The fatigue resistance of Inconel 718 is another critical mechanical property, especially in cyclic loading applications. Its ability to withstand repeated stress without failing makes it an ideal material for components subjected to fluctuating loads.

Creep Resistance

Inconel 718 also exhibits excellent creep resistance, a vital characteristic for high-temperature applications. This property ensures that the alloy can maintain its structural integrity over extended periods under stress at elevated temperatures.

Impact Strength

Inconel 718 demonstrates excellent impact strength and toughness. Notably, its Charpy V-notch impact values typically exceed 68 joules (50 ft-lbs) in the longitudinal direction at temperatures as low as -60°C (-76°F). The impact strength varies with direction in wrought products, with longitudinal properties generally superior to transverse properties. This exceptional impact toughness contributes to its resistance to brittle fracture and ability to absorb energy during sudden loading events, enhancing safety in critical applications.

Strengthening Mechanisms in Inconel 718

Inconel 718 owes its remarkable properties to various strengthening mechanisms that enhance its performance under extreme conditions. The combination of these mechanisms allows Inconel 718 to maintain its strength and resistance to corrosion and fatigue, making it an ideal material for demanding applications.

Precipitation Hardening

Precipitation hardening is a critical strengthening mechanism in Inconel 718, primarily achieved through the precipitation of γ″ and γ′ phases. The γ″ phase, with its body-centered tetragonal structure, is coherent with the matrix and provides significant strengthening. The γ′ phase, with its face-centered cubic structure, also contributes to the alloy’s strength. The combination of these precipitates results in a substantial increase in the alloy’s yield strength and resistance to deformation.

Solid Solution Strengthening

Solid solution strengthening in Inconel 718 is achieved through the dissolution of various elements, such as chromium, molybdenum, and niobium, in the nickel-iron matrix. These elements distort the crystal lattice, creating strain fields that impede dislocation movement, thereby enhancing the alloy’s strength and resistance to deformation. The presence of these elements in solid solution contributes significantly to the alloy’s overall mechanical properties.

Grain Boundary Effects

Grain boundary effects play a crucial role in the mechanical behavior of Inconel 718. The delta (δ) phase, which precipitates at grain boundaries, can pin grain boundaries and prevent excessive grain growth during high-temperature exposure, thus contributing to grain size stabilization. Additionally, the presence of carbides at grain boundaries can enhance strengthening, although excessive carbide networks can lead to reduced ductility. Understanding and controlling grain boundary effects are essential for optimizing the heat treatment processes to achieve the desired balance of strength, ductility, and high-temperature stability in Inconel 718 components.

Corrosion Resistance of Inconel 718

The corrosion resistance of Inconel 718 is one of its most significant advantages, contributing to its widespread use in harsh environments. This alloy is particularly valued for its ability to withstand a wide range of corrosive media, making it suitable for various industrial applications.

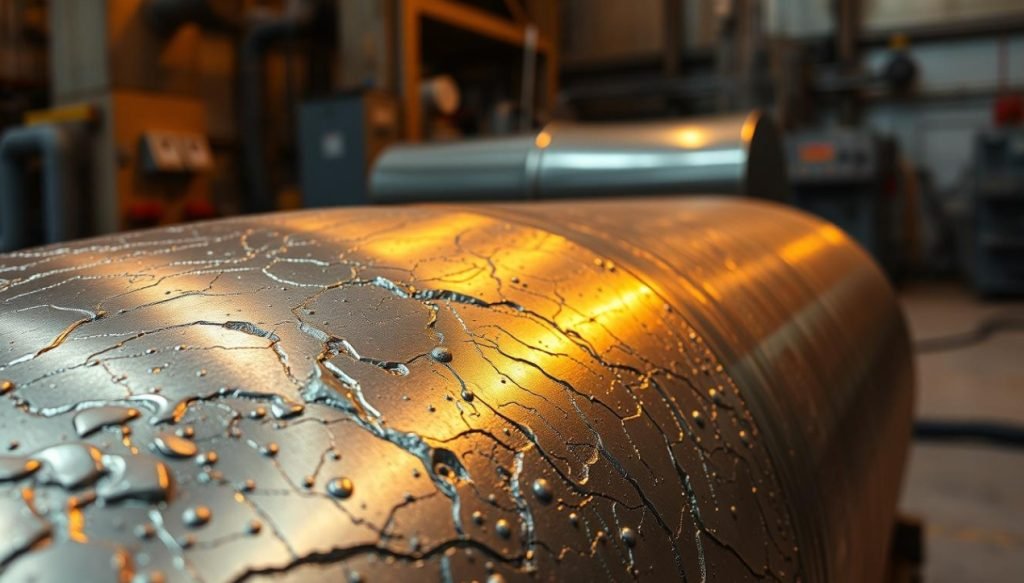

Oxidation Resistance at High Temperatures

Inconel 718 demonstrates excellent oxidation resistance at high temperatures, a critical property for applications in aerospace and power generation. When heated, Inconel 718 forms a thick, stable passivating oxide layer that protects the surface from further attack. This characteristic is essential for components that operate in high-temperature environments, ensuring they remain functional over their intended lifespan.

The alloy’s high chromium content plays a significant role in its oxidation resistance. Chromium reacts with oxygen to form a chromium oxide layer, which is highly stable and protective. This layer prevents further oxidation of the underlying metal, thereby enhancing the durability and reliability of components made from Inconel 718.

Resistance to Various Corrosive Environments

Inconel 718 also shows remarkable resistance to a variety of corrosive environments, including hot acids, seawater, and caustic solutions. This makes it an ideal material for chemical processing, oil and gas production, and marine applications. The alloy’s resistance to stress corrosion cracking is particularly noteworthy, especially in chloride-containing environments where many other high-strength alloys would fail rapidly under tensile stress.

Inconel 718 performs well in specific corrosive media, exhibiting excellent resistance to nitric acid, good resistance to sulfuric and phosphoric acids, and moderate resistance to hydrochloric acid. Generally, its performance improves at lower concentrations and temperatures. The corrosion resistance of Inconel 718 in aqueous environments is primarily attributed to its high nickel and chromium content, which promotes the formation of a passive film protecting the underlying metal.

Heat Treatment of Inconel 718

The heat treatment of Inconel 718 is a critical process that significantly influences its microstructure and properties. You will discover how this process optimizes the alloy for various high-performance applications.

Solution Treatment Process

The solution treatment process involves heating Inconel 718 to a high temperature, typically between 940°C to 1010°C, to dissolve the γ″ and γ’ precipitates. This step is crucial for achieving a uniform microstructure. The alloy is then quenched to retain the solutionized state.

Age Hardening Process

Following solution treatment, Inconel 718 undergoes an age hardening process. This involves heating the alloy to a lower temperature, typically around 720°C, to precipitate the γ″ and γ’ phases. The resulting microstructure exhibits a fine dispersion of these precipitates, significantly enhancing the alloy’s strength.

Effects on Microstructure

The heat treatment process dramatically transforms the microstructure of Inconel 718. After aging, the microstructure develops a fine dispersion of gamma double prime (γ”) precipitates and gamma prime (γ’) precipitates. Understanding these microstructural changes is crucial for optimizing heat treatment processes to achieve the desired combination of properties for specific applications.

Manufacturing Methods for Inconel 718

Manufacturing Inconel 718 involves a range of processes, from traditional techniques to advanced additive methods. The choice of manufacturing method depends on the specific application, component geometry, and required properties.

Traditional Manufacturing Techniques

Traditional manufacturing techniques for Inconel 718 include forging, casting, and machining. Forging is used to produce components with complex geometries, while casting is employed for parts with intricate internal structures. Machining is a critical process for achieving precise dimensions and surface finishes.

Inconel 718 is known to be difficult to machine due to its high strength and rapid work hardening characteristics. To overcome these challenges, manufacturers use rigid setups, sharp cutting tools, and optimized cutting parameters. Specialized cutting tool materials like coated carbides, ceramics, and cubic boron nitride (CBN) are often required.

Additive Manufacturing

Additive manufacturing (AM) has emerged as a viable option for producing complex Inconel 718 components. AM techniques, such as selective laser melting (SLM) and electron beam melting (EBM), allow for the creation of intricate geometries and reduced material waste. However, AM processes require careful control of parameters to achieve the desired microstructure and properties.

Challenges in Processing

Processing Inconel 718 presents several challenges, including high deformation resistance, rapid work hardening, and a narrow processing window. Hot working of Inconel 718 requires precise control of temperature and strain rate to avoid undesirable microstructural changes. Understanding these challenges is crucial for developing effective production strategies that minimize costs while maintaining the required quality and properties.

The difficulties in machining Inconel 718 are significant due to its high strength and relatively low thermal conductivity. Manufacturers must adopt specific cutting strategies and use specialized tool materials to overcome these challenges.

Machining and Joining Inconel 718

To effectively work with Inconel 718, understanding its machining and joining requirements is crucial. Inconel 718 is a versatile alloy used in various high-temperature applications, and its machining and joining processes are critical to maintaining its properties.

Machining Challenges and Techniques

Machining Inconel 718 poses several challenges due to its high strength and hardness. You need to employ specific techniques to overcome these challenges. The alloy’s tendency to work harden during machining can lead to tool wear and damage. To mitigate this, using sharp cutting tools and optimizing machining parameters such as speed and feed rate is essential.

Additionally, using coolant and lubrication during machining can help reduce heat generation and prolong tool life. By adopting these strategies, you can improve the efficiency and quality of the machining process for Inconel 718.

Welding and Joining Methods

Inconel 718 is considered one of the more weldable precipitation-hardened nickel superalloys, though joining still requires careful attention to procedure and technique. The most common welding processes for Inconel 718 include gas tungsten arc welding (GTAW/TIG), electron beam welding (EBW), and laser beam welding (LBW). Each of these methods offers specific advantages depending on the application requirements.

Proper pre-weld and post-weld heat treatments are critical when joining Inconel 718, as they significantly affect the microstructure and properties of both the weld and heat-affected zones. Potential welding challenges include hot cracking and segregation of alloying elements, which can be mitigated through proper filler metal selection and controlled heat input.

Applications of Inconel 718

The unique properties of Inconel 718 make it an ideal material for numerous industrial applications. You will find it being used in various sectors where its strength, corrosion resistance, and ability to withstand extreme temperatures are crucial.

Aerospace Industry Applications

Inconel 718 is widely used in the aerospace industry for components such as gas turbine blades, seals, and combustors. Its high-temperature strength and resistance to corrosion make it an essential material for these applications. Additionally, it’s used in turbocharger rotors and seals, and high-temperature fasteners.

Oil and Gas Industry Uses

In the oil and gas industry, Inconel 718 is utilized for electric submersible well pump motor shafts and other equipment that must withstand corrosive environments and high temperatures. Its resistance to corrosion and high-temperature strength make it suitable for natural gas processing with contaminants such as H2S and CO2.

Power Generation Applications

Inconel 718 is used in power generation for steam generators and core components in nuclear pressurized water reactors. Its ability to withstand extreme temperatures and corrosive environments makes it an ideal material for these applications.

Other Industrial Applications

Beyond aerospace, oil and gas, and power generation, Inconel 718 finds applications in numerous other industries. In the chemical processing industry, it’s used for pressure vessels, heat exchangers, and piping systems. In the automotive sector, Inconel 718 is used for exhaust components, turbocharger parts, and valve train components in high-performance and racing vehicles. Additionally, it’s used in waste incineration equipment, industrial furnace components, and pollution control systems.

Inconel 718 vs. Other Superalloys

In the landscape of high-temperature alloys, Inconel 718 emerges as a superior option due to its balanced properties and cost-effectiveness.

Comparison with Inconel 625

Inconel 718 and Inconel 625 are both popular nickel-chromium superalloys used in high-temperature environments. However, Inconel 718 offers a distinct advantage due to its gamma-double-prime strengthening mechanism, which provides better strength and weldability compared to Inconel 625. You can appreciate how this difference impacts the manufacturing process and the overall performance of the alloy.

Inconel 718’s ability to retain its strength over a wide temperature range, coupled with its resistance to corrosion and fatigue, makes it a preferred choice for applications where Inconel 625 might not suffice.

Advantages Over Other High-Temperature Alloys

Inconel 718 offers several distinct advantages over other high-temperature alloys, including an exceptional combination of high strength, good fabricability, and relatively lower cost. You will understand how its gamma-double-prime strengthening mechanism allows for better workability and weldability, making it more versatile in manufacturing complex components.

The alloy’s performance is further enhanced by its ability to be used in both age-hardened and solution-treated conditions, providing flexibility in manufacturing processes. Inconel 718’s widespread adoption across multiple industries has led to extensive knowledge of its processing, properties, and performance, reducing technical risk.

Future Trends in Inconel 718 Development

The future of Inconel 718 looks promising, with emerging trends and research areas expanding its potential. As industries continue to push the boundaries of operating conditions, the demand for high-performance materials like Inconel 718 is expected to grow.

Emerging Research Areas

Research into Inconel 718 is ongoing, with several emerging areas showing significant promise. You can expect to see advancements in the understanding of its properties and behavior under extreme conditions. New processing techniques and alloy modifications are being explored to further enhance its performance.

Some of the key research areas include the development of new heat treatment processes, the study of Inconel 718’s behavior in extreme environments, and the investigation of its potential in additive manufacturing.

Potential New Applications

Inconel 718 continues to find new applications in various industries. You’re likely to see its use in components for hypersonic vehicles, where its high-temperature strength and oxidation resistance are valuable. The growing hydrogen economy also presents opportunities for Inconel 718 in hydrogen production, storage, and utilization equipment.

Additionally, Inconel 718 is being considered for use in advanced energy systems, such as concentrated solar power and next-generation nuclear reactors, due to its combination of high-temperature strength and corrosion resistance. The advent of additive manufacturing is also enabling new design possibilities for Inconel 718 components with complex geometries.

As the development of Inconel 718 continues, you can expect to see its use in even more demanding applications, driving innovation and performance across multiple industries.

Conclusion

As you’ve explored the properties and uses of Inconel 718, it’s clear that this alloy plays a critical role in various industries. Inconel 718 is a precipitation-hardenable nickel-chromium alloy designed for high strength and corrosion resistance at temperatures from cryogenic to 1300°F (704°C).

Inconel 718 stands out as one of the most versatile and widely used superalloys, offering an exceptional combination of high strength, excellent corrosion resistance, and good fabricability. Its unique microstructure enables it to maintain mechanical properties at temperatures up to 650°C (1200°F), making it invaluable in numerous high-performance applications.

The comprehensive range of properties you’ve learned about, from thermal and physical characteristics to mechanical behavior and corrosion resistance, underscores the alloy’s value. The manufacturing methods, heat treatment processes, and joining techniques for Inconel 718 have been refined over decades, supporting its reliable application in critical components across various applications.

In summary, Inconel 718 will remain a crucial engineering material as industries continue to push the boundaries of performance and efficiency. Ongoing research and development are likely to extend its capabilities and applications further. With its robust properties and wide-ranging uses, Inconel 718 is poised to continue playing a vital role in advancing technology.

FAQ

What are the primary applications of this alloy in the aerospace industry?

You can utilize it in various high-temperature applications, such as engine components, due to its exceptional strength and resistance to corrosion and fatigue.

How does heat treatment affect the microstructure of the material?

The heat treatment process, including solution treatment and age hardening, significantly influences the microstructure, resulting in improved mechanical properties, such as tensile strength and hardness.

What are the challenges associated with machining and welding this alloy?

You may encounter difficulties during machining due to its high strength and hardness, while welding requires careful control of temperature and process parameters to prevent distortion and cracking.

How does the alloy resist corrosion in various environments?

The material exhibits excellent corrosion resistance due to the formation of a protective oxide layer, which shields it from corrosive substances, making it suitable for use in harsh environments.

What are the advantages of using this alloy over other high-temperature alloys?

You can benefit from its exceptional strength, resistance to fatigue and creep, and ability to withstand high temperatures, making it an ideal choice for demanding applications.

What are the emerging research areas related to this alloy?

Researchers are exploring new applications, such as advanced power generation systems, and investigating ways to improve its properties through innovative processing techniques and alloy development.

How does the coefficient of thermal expansion impact its performance?

The relatively low coefficient of thermal expansion helps minimize distortion and stress caused by temperature changes, ensuring the material’s stability and reliability in high-temperature applications.

What are the typical manufacturing methods used to produce components from this alloy?

You can manufacture components using traditional techniques, such as forging and casting, as well as additive manufacturing methods, which offer greater design flexibility and complexity.