Did you know that a significant portion of manufacturing costs is determined during the product design phase? Optimizing your product design for manufacturability can reduce costs by up to 70% while improving quality and time-to-market.

Design For Manufacturing (DFM) is a strategic approach that optimizes product design to enhance manufacturability. By simplifying, optimizing, and refining the product design, you can make a better product at a lower cost. As an engineer working with CNC machined parts or injection molded components, understanding DFM is crucial to remain competitive in today’s fast-paced manufacturing environment.

By implementing DFM early in the design process, you’ll be able to identify potential issues before they become costly problems, ensuring a smoother production process.

Understanding Design For Manufacturing (DFM)

To unlock manufacturing efficiency, it’s essential to grasp the concept of Design For Manufacturing (DFM) and its role in product development. DFM is a systematic approach that focuses on optimizing product design to facilitate easier, more efficient manufacturing processes.

Definition and Core Concepts of DFM

DFM stands for Design for Manufacturing or Design for Manufacturability. This manufacturing process occurs during the product development process when your design shifts from prototype development to new product introduction. When done correctly, it significantly lowers the cost and time of manufacturing components.

The core concepts of DFM include design simplification, standardization of components, and optimization for specific manufacturing processes like CNC machining or injection molding. By understanding these fundamental concepts, you can establish a solid foundation for implementing DFM principles in your product development workflow.

DFM vs. DFMA: Key Differences

You’ll learn how DFM differs from DFMA (Design for Manufacturing and Assembly), with DFM focusing primarily on individual part manufacturability while DFMA extends to include assembly considerations. This distinction is crucial in determining the appropriate approach for your product development needs.

Historical Development of DFM Practices

The historical development of DFM practices dates back several decades, evolving from simple manufacturing guidelines to comprehensive methodologies that integrate with modern CAD/CAM systems. This evolution has enabled designers to create products that are not only functional but also optimized for efficient manufacturing.

The Business Case for DFM

As a manufacturer, you’re likely aware that design decisions have a significant impact on production costs and product performance. About 70 percent of manufacturing costs are determined by design decisions, making it crucial to adhere to the best design practices possible.

Cost Reduction Benefits

Implementing DFM provides substantial cost reduction benefits by identifying and eliminating potential manufacturing issues early in the design process. This can lead to a reduction in manufacturing costs by up to 70% through optimized material selection, simplified designs, and streamlined production processes.

Quality Improvement Outcomes

Quality improvements are a natural outcome of DFM implementation, as the methodology focuses on designing products that are consistently manufacturable with fewer defects and variations. This results in higher quality products and reduced warranty claims.

Time-to-Market Advantages

Time-to-market advantages become apparent when you implement DFM, as it reduces the need for design revisions, tooling modifications, and manufacturing troubleshooting. This enables you to get your products to market faster, giving you a competitive edge.

The business case for DFM is compelling across industries, with companies reporting significant ROI through reduced warranty claims, increased customer satisfaction, and improved product performance. Understanding these benefits helps you justify the investment in DFM processes and tools, especially when competing in industries where margins are tight and quality expectations are high.

The DFM Timeline: When to Implement

To maximize manufacturing efficiency, it’s essential to understand when to integrate DFM into your product development cycle. The timing of DFM implementation can significantly impact the overall production process.

Early Integration in Product Development

Ideally, DFM should occur early in the design process, well before tooling has begun. This allows for design changes to be executed quickly and at the least expensive stage. Implementing DFM early can reduce design change costs by up to 80% compared to making changes during production.

DFM for Existing Products

For existing products, DFM can still provide significant benefits through redesign efforts, although the cost savings may be less dramatic than with new product development. Manufacturers can still achieve improvements by applying DFM principles to existing designs.

Typical Duration of the DFM Process

The typical duration of a DFM process ranges from a few weeks for simple products to several months for complex designs with multiple components and manufacturing processes. Factors affecting the DFM timeline include product complexity, team size, available information, and the specific DFM tools being used.

Today’s manufacturers recognize that allocating sufficient time for thorough DFM analysis pays dividends through smoother production ramp-up and fewer post-launch issues. By understanding the optimal time to implement DFM and its typical duration, you can better plan your product development cycle to maximize manufacturing efficiency.

5 Core Principles of DFM

Effective Design For Manufacturing (DFM) relies on five core principles that work together to optimize product design for efficient production. These principles are fundamental to creating manufacturable designs that meet product requirements while minimizing production costs and maximizing quality.

Process Optimization

Process optimization is a critical principle of DFM that involves selecting the most appropriate manufacturing process for your specific part or product requirements. This includes considering factors such as production volume, material properties, and desired product characteristics to ensure that the chosen process is the most efficient and cost-effective.

Design Simplification

Design simplification is another key principle of DFM that focuses on reducing the complexity of product designs to improve manufacturability. Strategies such as minimizing part count, standardizing components, and eliminating unnecessary features can significantly simplify the manufacturing process, reduce production costs, and improve product reliability.

Material Selection Strategies

Material selection is a crucial aspect of DFM that requires careful consideration of various factors, including functional requirements, manufacturing process compatibility, cost considerations, and performance properties. By selecting the most suitable materials for your product, you can ensure that it meets the required specifications while minimizing production costs and environmental impact.

Environmental Considerations

Environmental considerations are essential in DFM, as they ensure that your product is designed to withstand its intended operating conditions, including temperature extremes, moisture, vibration, and other environmental factors. By taking these factors into account during the design phase, you can improve product reliability, reduce maintenance costs, and enhance overall customer satisfaction.

Compliance and Testing Requirements

Compliance and testing requirements are critical components of DFM that ensure products meet industry standards, regulatory requirements, and safety specifications. By integrating these requirements into the design process, you can avoid costly redesigns, reduce the risk of product failures, and ensure that your products are compliant with relevant regulations and standards.

By applying these five core principles of DFM, you can create product designs that are optimized for manufacturing efficiency, quality, and cost-effectiveness. This comprehensive framework guides engineers through the process of creating designs that are not only functional and reliable but also manufacturable and sustainable.

The DFM Implementation Process

You can significantly improve your product’s manufacturability by following a well-planned DFM implementation process. This process involves several key steps that help ensure your product is designed with manufacturing efficiency in mind.

Stakeholder Involvement

The DFM implementation process begins with comprehensive stakeholder involvement, bringing together engineers, designers, manufacturers, suppliers, and quality assurance personnel. This collaborative approach ensures that all aspects of the product development process are considered.

Cross-Functional Team Formation

Forming cross-functional teams creates a collaborative environment where diverse expertise can be leveraged to identify and solve potential manufacturing issues. By working together, these teams can optimize the design and manufacturing process.

Design Review Methodology

The design review methodology should follow a structured approach, examining the design at component, sub-system, and system levels to ensure manufacturability at every stage. This thorough review helps identify potential issues early in the product development cycle.

Iterative Refinement Process

Iterative refinement is essential to the DFM process, with each design iteration incorporating feedback from manufacturing experts and addressing identified issues. This process ensures that the final product design is optimized for manufacturing efficiency.

Successful DFM implementation requires clear communication channels, established metrics for measuring success, and a commitment to continuous improvement throughout the product development cycle. By working closely with your contract manufacturer during the DFM process, you can ensure that their specific capabilities and constraints are considered in the design, leading to more efficient production.

Essential DFM Tools and Technologies

Several key tools and technologies are crucial for successful DFM implementation. These tools enable designers and manufacturers to create optimized product designs, simulate manufacturing processes, and collaborate effectively throughout the product development cycle.

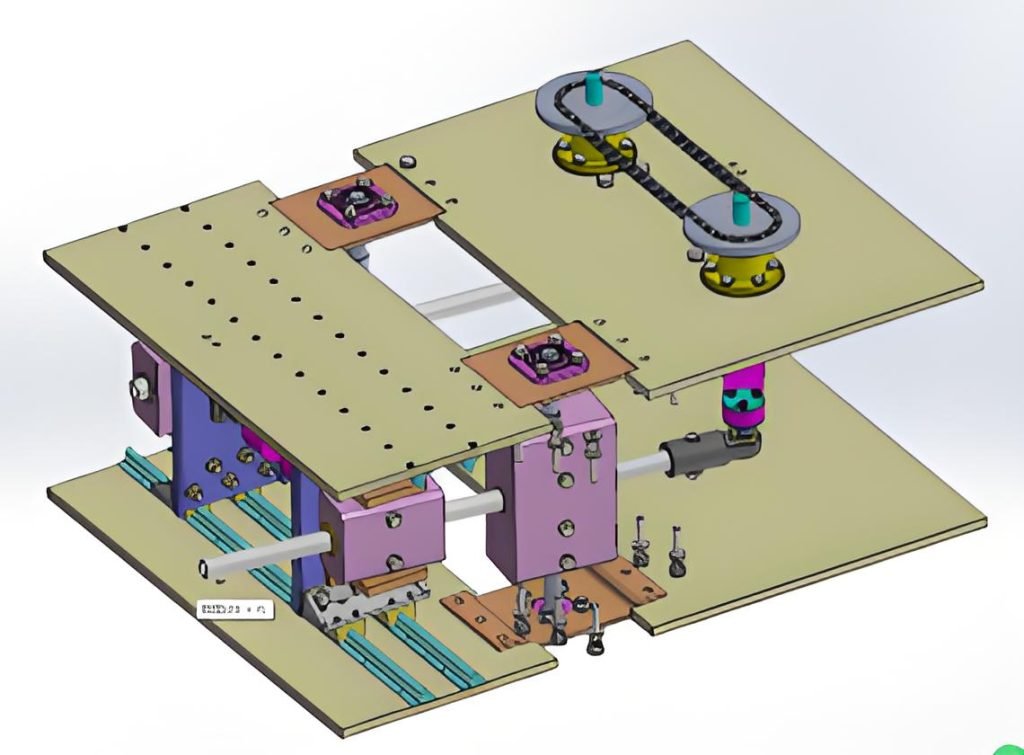

Design Software

Design software solutions like SolidWorks, Fusion360, and AutoCAD provide the foundation for DFM by enabling the creation of detailed 3D models that can be analyzed for manufacturability. These tools allow designers to identify potential manufacturing issues early in the design process.

Simulation and Analysis Tools

Simulation and analysis tools, such as Moldflow for plastic injection molding or FEA software for structural analysis, help identify potential manufacturing issues before physical prototyping. These tools enable designers to predict product performance under various conditions, reducing the risk of costly redesigns.

Process Modeling Applications

Process modeling applications allow engineers to simulate specific manufacturing processes, predicting how materials will behave during production and identifying potential defects or inefficiencies. This enables the optimization of manufacturing processes and improves product quality.

Collaboration Platforms

Collaboration platforms facilitate communication between design teams, manufacturing engineers, and suppliers, ensuring that all stakeholders can contribute their expertise to the DFM process. This fosters a more integrated and efficient product development process.

By leveraging these essential DFM tools and technologies, manufacturers can significantly reduce development time and improve first-pass manufacturing success rates. The integration of artificial intelligence and machine learning capabilities in modern DFM tools further enhances their effectiveness.

Critical Factors in DFM Analysis

When analyzing a product’s design for manufacturability, several critical factors come into play to ensure efficiency and cost-effectiveness. A thorough DFM analysis is essential for minimizing production costs and maximizing product functionality.

Minimizing Part Count

Reducing the number of parts in a product is a fundamental DFM strategy. By minimizing part count, you can decrease material costs, reduce engineering time, and simplify production labor and assembly. This approach also reduces assembly complexity, making it easier to manufacture and assemble the product.

Standardizing Components

Standardizing parts and materials is another crucial aspect of DFM analysis. Using readily available components can significantly reduce lead times and leverage economies of scale in purchasing. This strategy helps in avoiding customization and personalization, which are often expensive and time-consuming.

Managing Tolerances

Tolerance management is critical in DFM analysis. Overly tight tolerances can dramatically increase manufacturing costs without providing proportional benefits to product functionality. It’s essential to strike a balance between tolerance specifications and manufacturing costs to ensure cost-effectiveness.

Assembly Efficiency Considerations

Designing parts that can be assembled in a single direction, preferably from above, is a key consideration for assembly efficiency. Minimizing handling requirements and reducing the need for specialized tools also contribute to a more efficient assembly process. By optimizing assembly efficiency, you can reduce production time and costs.

Selecting the Right Manufacturing Process

The choice of manufacturing process must align with design features, production volume, and cost targets. For instance, plastic injection molding is ideal for high-volume production but requires significant upfront tooling investment. Understanding the strengths and limitations of various manufacturing processes can help you make informed design decisions that balance manufacturability with product performance, ultimately creating designs that are both functional and cost-effective to produce.

DFM for Specific Manufacturing Processes

Different manufacturing processes require unique DFM approaches to achieve optimal results. By understanding the specific DFM considerations for each process, you can maximize the benefits of your chosen production method.

CNC Machining

For CNC machining, DFM focuses on minimizing setup time, tool changes, and part reorientations. This involves designing parts with feature accessibility in mind, selecting materials that are easy to machine, and specifying tolerances that balance precision with cost.

Injection Molding

When it comes to injection molding, DFM guidelines include maintaining uniform wall thickness, incorporating appropriate draft angles, avoiding undercuts, and designing parts that can be easily ejected from the mold. For example, a constant wall thickness allows for consistent and quick part cooling, while a draft angle of 1-2 degrees is usually acceptable.

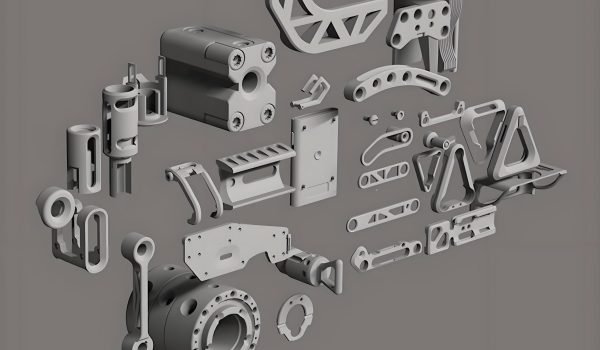

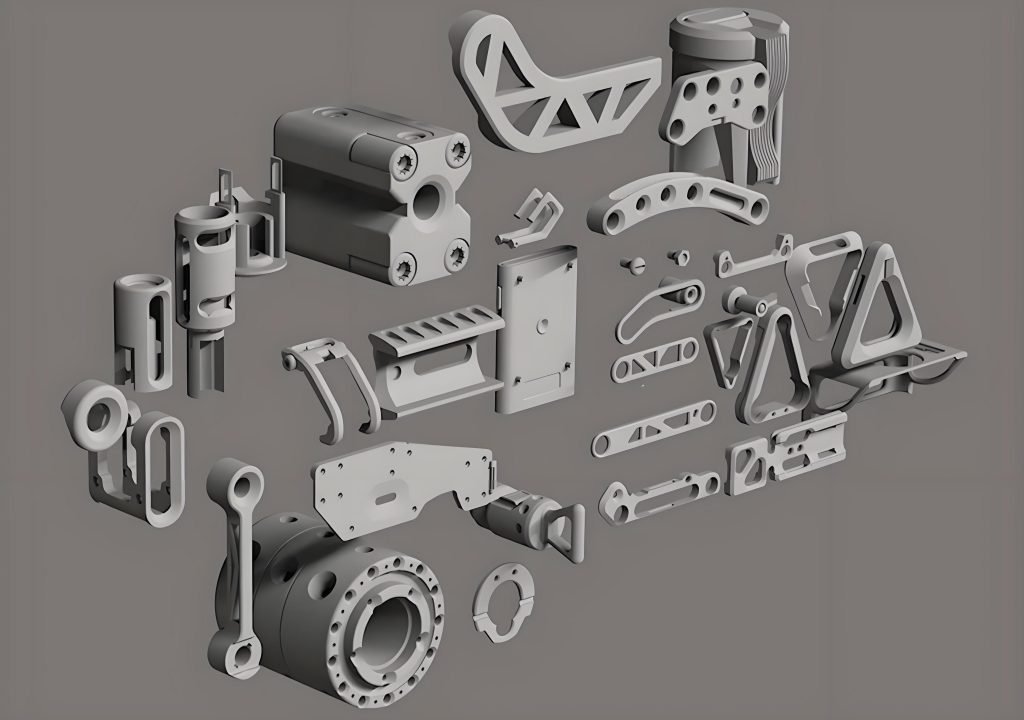

Additive Manufacturing

For additive manufacturing (3D printing), DFM principles differ significantly, focusing on orientation optimization, support structure minimization, and design features that leverage the unique capabilities of layer-by-layer fabrication.

PCB and Electronics

DFM for PCB and electronics addresses component placement, thermal management, signal integrity, and manufacturing standards compliance to ensure reliable production of electronic assemblies.

By tailoring your DFM approach to the specific manufacturing process, you can maximize the benefits of each production method while avoiding its particular limitations and challenges.

Conclusion: Maximizing Manufacturing Success Through DFM

As we’ve explored, DFM plays a vital role in bridging the gap between product design and manufacturing reality. By implementing DFM early in the product development process, you can reduce manufacturing costs by up to 70% while improving quality and reducing time-to-market.

By applying the five core principles of DFM and leveraging process-specific guidelines, you can create manufacturable designs that meet customer requirements for price, specification, material, and scheduling, ultimately driving business success.