Delrin CNC machining has become a cornerstone of modern precision manufacturing, especially for industries that demand lightweight, durable, and dimensionally stable components. It is known for its excellent mechanical properties and machinability. Delrin (also referred to as POM or acetal) is widely used to produce high-performance plastic parts that rival metals in many functional applications. Delrin bridges the gap between metal and conventional plastics.

This article explains everything you need to know about CNC machining Delrin and how to choose a reliable Delrin precision machining service like Fengchi. Whether you are an engineer, purchasing manager, or product designer, this guide will help you determine if Delrin CNC machining is the right solution for your project.

What Is Delrin and Why Is It Used in CNC Machining

Delrin is a high-performance engineering plastic produced by acetal homopolymer that is characterized by superior strength, stiffness and dimensional stability. It is developed by DuPont. Delrin is unique in terms of its balance of properties. It is characterized by an incredible rigidity but is not so rigid that it can crack.

It has a high fatigue rating, reduces moisture uptake and has a broad operating temperature span (dimensionally). Moreover, Delrin provides high chemical resistance to a very broad spectrum of solvents, fuel, and neutral chemicals.

Delrin vs. POM vs. Acetal: What’s the Difference?

These terms have distinct meanings though often used interchangeably.

- Acetal is the general name for polyoxymethylene (POM).

- POM refers to the polymer family, which includes both homopolymer and copolymer variants.

- Delrin is DuPont’s branded acetal homopolymer.

Compared to acetal copolymers, Delrin homopolymer provides higher stiffness, better fatigue resistance, and improved machinability. These advantages make Delrin especially suitable for precision POM CNC machining applications where tight tolerances and consistent performance are required.

Why Delrin Is Ideal for Precision Machining

The material’s homogeneous structure makes Delrin particularly well-suited for CNC machining. Unlike many plastics, it machines similarly to aluminum, creating clean, precise cuts with minimal tool wear.

Delrin produces fine chips rather than melting during machining, allowing for excellent surface finishes without special cooling requirements. Its dimensional stability during and after machining ensures components maintain their specified tolerances, even when exposed to varying environmental conditions or mechanical stresses.

Delrin CNC Machining Process Explained

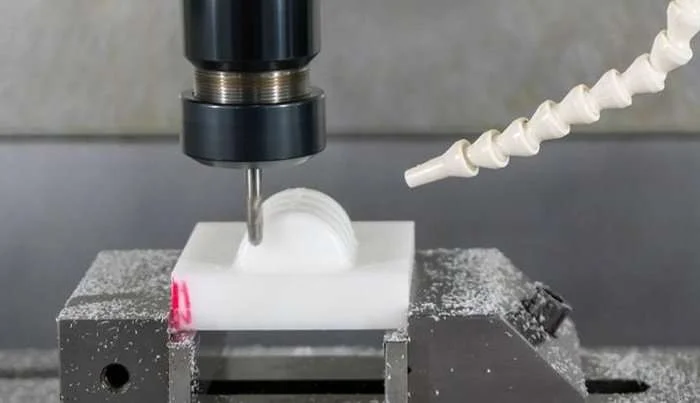

The machining process for Delrin begins with proper tool selection and parameter settings to achieve optimal results. Unlike many materials, Delrin can be machined with standard equipment yet delivers exceptional precision.

CNC Milling of Delrin

Delrin must be machined using sharp cutting tools with positive rake angles to avoid the tear effect. Single-fluted mills are favored due to less heat generation through friction and more chip clearance.

To achieve the best performance, the recommended cutting speeds are 300-500 Sf/m and depth cuts 0.05-0.10 inches. Therefore, it is necessary to regulate the accumulation of heat because Delrin becomes soft when heated, which can lead to distortion.

CNC Turning of Delrin

Delrin is converted into precise cylindrical parts such as bushings, seals, and shafts through the process of turning. Normal metal-working lathes with ground tool bits (like those in brass) make great work.

Basically, the most excellent finish is the result of rapid speeds and a small feed rate. Chip breakers and back rakes are used to assist in removing drag in the turning process, particularly where tight tolerances of +-0.002″ are needed.

Drilling, Tapping, and Threading Delrin

Standard twist drills work effectively with Delrin, although coolant becomes necessary for holes deeper than twice their diameter. For tapping operations, sourcing the correct tap grade ensures optimal results, specifically one designed for plastic materials. Regarding threading, conventional equipment with high-speed chasers produces clean threads, primarily making successive cuts of 0.15-0.25mm.

Benefits of Delrin CNC Machining

Delrin is widely used in precision CNC machining due to its strong balance of durability, accuracy, and performance. Its unique properties make it ideal for high-quality parts used in many industries.

- Great dimensional stability and accuracy: Delrin maintains its shape exceptionally well, regardless of pressure, stress, or humidity changes. CNC machined Delrin components can have tight tolerances of +-0.001 to +-0.005 inches and are ideal in components where accuracy is paramount, like automotive components and medical apparatuses.

- Low friction and self-lubricating: Delrin provides a low coefficient of friction, with a range of 0.2 to 0.35. This minimizes wear, and also extra lubrication is unnecessary, so POM Delrin acetal CNC machining is ideal in gears, bearings and moving assemblies.

- Excellent wear and impact resistance: Delrin is tough and durable. It is high in tensile strength and impact resistance, and parts can withstand repetitive stress during extended intervals. Its rigidity also contributes to the performance of components in harsh mechanical conditions.

- Moisture and chemical resistance: Delrin does not take in moisture easily, thus it works in wet or damp environments. It is also strong against most chemicals such as fuels, oils, solvents and alcohols, allowing the parts to last longer in extreme environments.

- Lightweight, yet strong: Despite being lightweight, Delrin offers high strength. This excellent strength-to-weight ratio has made it applicable in sectors such as aerospace and automobile production where weight reduction enhances efficiency.

- Electrical insulation properties: Delrin has excellent electrical insulating properties. It can securely isolate electrical elements and yet offers mechanical strength, which is why it may be used in some specific electronic and electrical devices.

Challenges and Limitations of Machining Delrin

Despite its advantages, acetal machining presents some challenges.

- Thermal sensitivity and heat buildup: Delrin may distort under high temperatures. The heat involved in CNC machining can lead to warping, particularly on flat or thin sections. Air cooling is commonly applied by machinists to minimize heat accumulation.

- Chip removal and burr formation: Delrin can form long, string-like chips during machining, and these chips may stick to tools, lowering the quality of cutting. Burrs can also develop at edges. Thus, effective chip removal and deburring are required to produce clean finishes.

- Poor adhesion and bonding: Delrin does not adhere to adhesives because it is chemically stable. Special surface treatment like roughening or plasma treatment, is often essential to enhance bonding.

- Flammability hazards: Delrin is easily burned and not self-extinguishing. It must be treated with care in hot or flammable conditions. In the event of a fire, only Class A fire extinguishers can be applied.

- Greater material cost: Delrin is more expensive than many other engineering plastics. Nevertheless, its high price is indicative of its dependability, durability, and stability.

Applications and Surface Finishing Options

Versatility defines Delrin machined components, with applications spanning across diverse industries where precision and durability are paramount.

Common Industries Using Delrin Machined Parts

Automotive manufacturers apply Delrin in gears, fuel system parts, bushings, and seat belt mechanisms where wear resistance comes in handy. Delrin is also used in aerospace applications, where it has a strength-to-weight ratio advantage in actuators and bearing housings.

Delrin is used in medical practice to make the handles of surgical instruments and diagnostic devices that need to be biocompatible. Its great electrical insulation properties make it a favorite with electronics manufacturers in connectors, insulators, and switches.

Surface Finish Types: As-machined, Polished, Bead Blasted

As-machined Delrin surfaces exhibit tool marks with roughness that extends to Ra 3.2 um, mainly used as internal parts where looks are not decisive. Polishing is used to produce a smooth finish, followed by high-gloss polish, suitable for visible parts and consumer products. Bead blasting, or firing small beads at the surface under pressure, creates a smooth, matte texture, ideal in non-reflective use.

When to Apply Protective Coatings

Protective coatings enhance scratch resistance yet must remain compatible with Delrin’s chemistry. These coatings typically benefit components exposed to harsh environments or decorative elements. Notably, Delrin’s surface inherently resists bonding, often requiring primers, etching, or plasma treatment for coating adhesion.

Designing for Esthetics vs. Function

Regarding design choices, functional components like gears, bushings, and spacers typically need no additional finishing, given Delrin’s natural low-friction surface. For customer-visible parts, consider specifying polishing or light bead blasting to enhance appearance. Leading manufacturers like Fecision offer precision Delrin machining services with superior quality, tolerances, and surface finishes for both esthetic and functional requirements.

Choosing the Right Delrin CNC Machining Partner

Selecting an expert partner for Delrin CNC machining significantly impacts your project’s success. Since not all manufacturers possess equal capabilities, understanding what differentiates the exceptional from the average becomes essential.

What to Look for in Delrin Machining Services

First, consider the experience of the manufacturer in acetal machining. An excellent manufacturer must know the functionality of Delrin and understand the other varieties like the Delrin 150 and Delrin 570, which have varying strength levels.

Then, check their equipment and accuracy. High-precision applications Parts with tight Delrin machining tolerances, including +-0.005 inches, can be machined in reliable CNC shops. It is desirable also when they provide various Delrin choices. This extends to standard Delrin, but also special varieties like PTFE-filled Delrin to reduce friction and glass-filled Delrin to provide better strength and stability.

Lastly, look at their turnaround time and quality of services. Efficiency is demonstrated by fast production times, beginning with about three days. A company that provides full services, from design support to finishing, can save you time and reduce the need to work with multiple suppliers.

Why Fecision Is a Trusted Delrin CNC Machining Manufacturer

Fecision is a reliable Delrin CNC machining vendor and has experience in dealing with all forms of Delrin materials. Our engineers cooperate with clients during the initial conversation through the final delivery to ensure that all the components are up to the specifications.

Our precision is up to +-0.005 inches and include both prototype work and production volumes. Fecision can be trusted with Delrin CNC machining projects due to their expertise and full-service approach.

Conclusion

Delrin CNC machining is an excellent choice for projects that demand high precision, strength, and long-term dimensional stability. Its low friction, wear resistance, and moisture tolerance make it ideal for automotive components, medical devices, electronics, and industrial parts.

Delrin performs best when tight tolerances, smooth finishes, and reliable performance are critical. However, achieving optimal results requires expert handling of machining parameters and quality control. Professional Delrin CNC machining services add value through experience, advanced equipment, and consistent accuracy.

If you are looking for reliable and high-quality Delrin machined parts with tight tolerances and fast lead times? Contact Fecision today to request a quote for Delrin precision CNC machining and custom acetal solutions.