How do modern manufacturers achieve precision and efficiency in their production processes? The answer lies in computer-aided manufacturing (CAM), a revolutionary technology that transforms digital designs into physical products with unprecedented accuracy.

The benefits of CAM are numerous, including improved productivity, enhanced product quality, and reduced waste. As a result, CAM has become an indispensable tool in modern manufacturing, adopted across various industries.

Understanding Computer-Aided Manufacturing (CAM)

Definition and Basic Concept

CAM is a technology that uses computer software to control machine tools and related machinery in manufacturing processes. It serves as the critical link between digital design and physical production, translating computer models into manufacturing instructions. By utilizing CAM, manufacturers can automate various production tasks, enhancing efficiency and precision.

The basic concept of CAM revolves around its ability to streamline manufacturing operations. By leveraging CAM software, manufacturers can optimize production workflows, reduce manual intervention, and improve product quality. This integration of CAM into manufacturing processes has transformed the industry, enabling the production of complex parts with high accuracy.

Evolution of CAM Technology

The history of CAM can be traced back to the post-World War II era with the first numerical control (NC) machines, which evolved into computer numerical control (CNC) in the 1960s.

As computing power has advanced, CAM has progressed alongside, allowing for increasingly complex manufacturing operations to be automated. Modern CAM systems are capable of controlling a wide range of machinery, from CNC milling machines to industrial robots, thereby expanding the possibilities in manufacturing. This progression has significantly impacted the production landscape, enabling manufacturers to achieve higher levels of precision and efficiency.

Components of Computer-Aided Manufacturing

To understand the inner workings of Computer-Aided Manufacturing (CAM), it’s essential to explore its core components. The effectiveness of a CAM system depends on the harmonious operation of its hardware and software elements.

Hardware Components

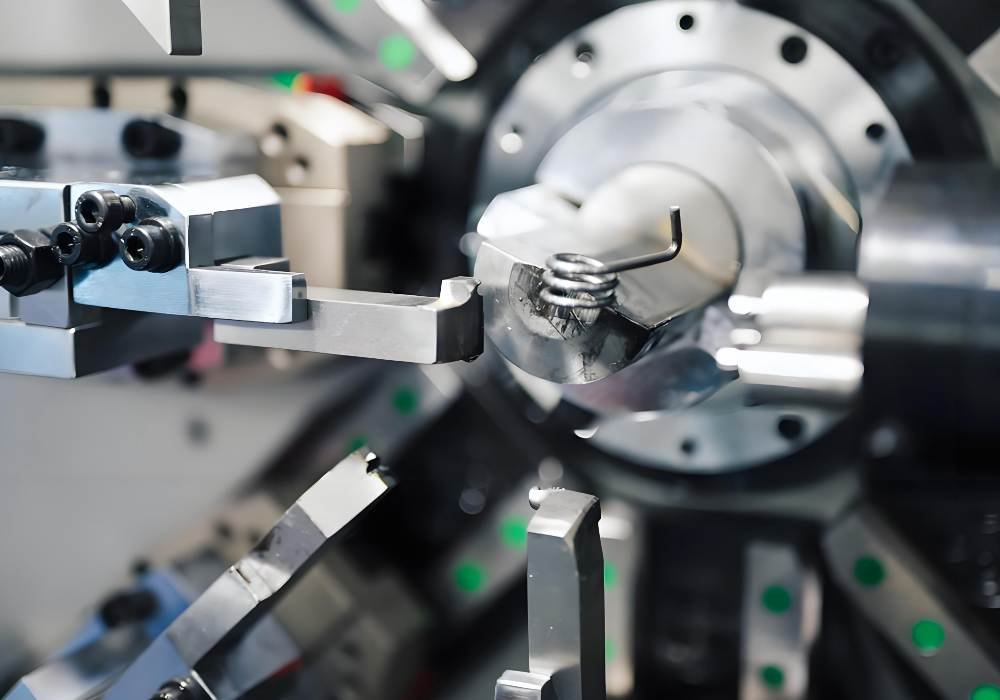

The hardware components of CAM systems include the physical machinery that executes manufacturing operations, such as CNC machines, robots, and specialized tools. Machine controllers play a critical role in interpreting programming instructions and converting them into precise mechanical movements. Additionally, measurement and feedback systems work to maintain accuracy and quality throughout the manufacturing process.

Software Components

The software components encompass specialized CAM programs that generate toolpaths, simulate manufacturing processes, and create machine-readable instructions, known as G-code. Post-processors serve as translators between CAM software and specific machine controllers, ensuring compatibility across different equipment. By working together, these hardware and components enable the production of complex parts with high precision.

How Computer-Aided Manufacturing Works

The CAM process is a sophisticated system that transforms digital designs into physical products through precise machining operations. You will learn how CAM software plays a crucial role in this transformation.

The CAM Process Flow

The CAM process begins with importing a digital design, typically a CAD model, into specialized CAM software. Here, you define manufacturing parameters, and the software analyzes the geometry of the part to determine the optimal toolpaths needed to create the physical component.

The system then generates specific instructions for machine movements, tool changes, and operational parameters based on the selected manufacturing strategy. This step involves applying machining strategies to generate toolpaths, which are critical for the manufacturing process.

G-Code Generation and Machine Control

The instructions generated by the CAM software are then converted into G-code, the universal programming language that CNC machines understand and follow. You will understand how the machine control system interprets the G-code and coordinates the precise movements of tools and workpieces to create the final product.

Feedback systems continuously monitor the manufacturing process to ensure accuracy and make adjustments when necessary. This ensures that the final product meets the required specifications and quality standards.

The CAD to CAM Process

As you explore the world of computer-aided manufacturing, understanding the CAD to CAM process is essential. This process represents the crucial bridge between product design and physical manufacturing, ensuring that design intent is accurately translated into production instructions.

Integration Between Design and Manufacturing

The CAD to CAM process involves transferring design data from CAD software to CAM systems. This integration eliminates manual data entry, reduces errors, and increases efficiency. Modern integrated systems allow for seamless data transfer between design and manufacturing environments, eliminating traditional communication barriers.

Data Transfer and Translation

The CAD model contains geometry, measurements, material specifications, and other properties necessary to describe the exact model. This data is then imported into CAM software to define machine processes. Various data exchange formats are used to transfer complex 3D models from CAD to CAM systems while preserving critical design information. Feature recognition technology in advanced CAM systems can automatically identify manufacturable elements from CAD models and suggest appropriate machining strategies.

By streamlining the transition from design to production, the CAD to CAM process has dramatically reduced time-to-market for new products. Design changes in CAD can be efficiently updated in CAM programs without starting the programming process from scratch, further enhancing productivity.

Basic Functions of Computer-Aided Manufacturing Systems

At the heart of CAM systems are three primary functions that work together to ensure accurate and efficient manufacturing operations. You will explore how these functions are crucial for optimizing the machining process.

Toolpath Generation

Toolpath generation is the core function of CAM systems, where the software calculates the most efficient routes for cutting tools to follow when removing material. Different machining strategies require specialized toolpath algorithms to optimize cutting efficiency and part quality.

Simulation and Verification

The simulation and verification capabilities of CAM software allow you to virtually test manufacturing programs before running them on actual machines. This identifies potential collisions, gouges, or inefficiencies, and realistic 3D simulations can predict machining time, material removal rates, and surface finish quality.

Post-Processing

Post-processing functions translate generic toolpath data into the specific machine control language needed for your particular equipment. This accounts for unique machine capabilities and limitations, ensuring that the manufacturing process is optimized for the machinery being used.

By understanding how these three fundamental functions work together, you can appreciate how advanced CAM systems can automatically adjust toolpaths based on material conditions, tool wear, and machine dynamics to maintain optimal cutting conditions.

Benefits of Computer-Aided Manufacturing

By leveraging CAM systems, manufacturers can significantly enhance their production efficiency and product quality. The integration of CAM technology into the manufacturing process has numerous benefits, ranging from improved efficiency and productivity to enhanced precision and quality.

Improved Efficiency and Productivity

CAM systems dramatically improve manufacturing efficiency by optimizing toolpaths, reducing idle time, and minimizing unnecessary machine movements. This enables manufacturers to increase productivity by enabling lights-out manufacturing, where machines can operate unattended for extended periods.

Enhanced Precision and Quality

The precision offered by CAM technology ensures consistent part quality with dimensional accuracy that would be impossible to achieve through manual methods. Automated quality verification within CAM systems can detect and correct manufacturing issues before they result in scrapped parts, further enhancing product quality.

Cost Reduction and Material Optimization

CAM systems contribute to cost reduction through decreased labor requirements, extended tool life via optimized cutting conditions, and reduced setup times between production runs. Material optimization algorithms can nest parts efficiently to minimize waste, particularly when working with expensive materials, thus reducing production costs.

These benefits combine to provide manufacturers with a competitive edge through faster time-to-market, higher quality products, and lower production costs. Moreover, CAM systems contribute to sustainability goals by reducing energy consumption and material waste throughout the manufacturing process.

Applications of Computer-Aided Manufacturing

With its ability to automate and optimize production processes, CAM has become a crucial element in modern manufacturing. You can see its impact across various industries that rely on CAM for producing complex components with high precision and consistency.

Automotive Industry

In the automotive sector, CAM technology enables the production of complex engine components, transmission parts, and body panels with the precision required for modern vehicles. Automotive manufacturers use CAM to rapidly prototype new designs and quickly transition to mass production, significantly reducing development time.

Aerospace Manufacturing

The aerospace industry relies heavily on CAM for machining critical components from exotic materials that must meet extremely tight tolerances and rigorous safety standards. Advanced CAM software allows aerospace manufacturers to create complex turbine blades and structural components from solid blocks of material using 5-axis machining.

Electronics Production

In electronics production, CAM systems control the manufacturing of circuit boards, semiconductor components, and electronic housings with microscopic precision. This level of accuracy is crucial for producing high-quality electronic products that meet stringent industry standards.

Medical Device Manufacturing

The medical device industry uses CAM to produce customized implants, surgical instruments, and diagnostic equipment that must meet strict regulatory requirements. CAM’s flexibility allows for the cost-effective production of personalized medical devices tailored to individual patient anatomy.

By adopting CAM technology, these industries have enhanced their manufacturing capabilities, improved product quality, and reduced production costs. As CAM continues to evolve, its applications are likely to expand into new areas, driving further innovation in manufacturing.

Conclusion: The Future of Computer-Aided Manufacturing

As we look to the future, Computer-Aided Manufacturing (CAM) is poised to revolutionize the manufacturing landscape. Emerging technologies like artificial intelligence and machine learning are making CAM systems more autonomous and adaptive. Today’s CAM technology is evolving toward fully integrated digital manufacturing ecosystems, connecting design, production, and quality control in real-time.

Cloud-based CAM solutions are enabling unprecedented collaboration between distributed manufacturing teams. The convergence of traditional subtractive manufacturing with additive manufacturing is creating hybrid CAM systems. As CAM technology advances, manufacturers who embrace these innovations will gain significant competitive advantages in speed, quality, and cost-effectiveness.