An estimated 65% of assembly defects trace back to improper bonding or welding of plastic parts, a surprising gap that costs manufacturers time and margin.

You need a clear, practical guide so you can choose the right method for your parts. We’ll highlight what each process demands from materials and part design, and how early choices affect service life, leak resistance, and aesthetics. You’ll see which technologies deserve early consideration for manufacturability and quality.

This guide gives you a step-by-step way to shortlist and validate processes, de-risk scale-up, and avoid late-stage rework. Use it to weigh total cost, cycle time, and throughput so your selection supports volume and margin goals.

What Are Plastic Joining Techniques and When Should You Use Them?

How you connect molded components can make or break durability, assembly time, and warranty costs. Choose the right approach early so your design and production stay aligned.

Why plastics joining matters for performance, cost, and manufacturability:

The joint usually dictates leak tightness, service life, and field reliability. Good selection lowers rework and warranty risk across many applications. It also shapes fixturing, tolerances, and cycle time, so you should design parts with the end process in mind.

Welding vs. adhesives/fasteners vs. overmolding: where each fits

Welding uses heat and pressure to create a molecular bond without extra hardware. That often improves part integrity and supports fast, repeatable production for many parts and materials.

Adhesives or solvents work when you have mixed materials or low-stress assemblies. Expect cure time, fumes, and long-term stability to affect production and reliability.

Mechanical fasteners let you disassemble for service but add components and stress points. Overmolding can replace multiple steps by combining one part with another, improving sealing, damping, and electronics protection while raising tooling cost and mold complexity.

Match the process to load cases, temperature, fluid exposure, and regulatory needs to decide whether a welded bond or an assembled joint is best for your application.

Common Types of Plastic Parts Connection Methods

When you assess connection options, focus on how motion, heat delivery, and flash control affect seal quality and throughput. Below is a compact, practical overview of each major method so you can match a process to your part geometry and cleanliness needs.

Ultrasonic welding

Ultrasonic welding delivers short vibrational pulses through a horn to melt small features fast. Use it for rigid parts, metal insert staking, and spot welds where localized energy and short cycle time matter.

Spin welding

Spin welding rotates one piece against a stationary mate to create circular welds. This spin method is cost-effective for round parts like caps and reservoirs and often yields hermetic seals with uniform melt.

Vibration welding

Vibration welding uses linear back-and-forth motion to generate heat at the interface. Typical amplitudes are about 1 mm at 240 Hz or 2 mm at 100 Hz.

It handles larger or irregular parts but can create jagged flash and particulates, so design flash traps when geometry allows.

Hot plate welding

Hot plate welding melts both faces against a controlled platen, then presses them together to form strong, often hermetic joints. It’s reliable for medium-to-large assemblies with repeatable cycle timing.

Infrared welding

Infrared is a non-contact option using medium-wave emitters at ~1 mm standoff to preheat surfaces. After the parts absorb energy, you press them to form a controlled bond with low contamination risk.

Clean Vibration Technology (CVT)

CVT adds IR preheat before vibration to bypass dry friction. That reduces particulate and yields compact flash when flash traps aren’t possible but high strength and hermetic sealing are required.

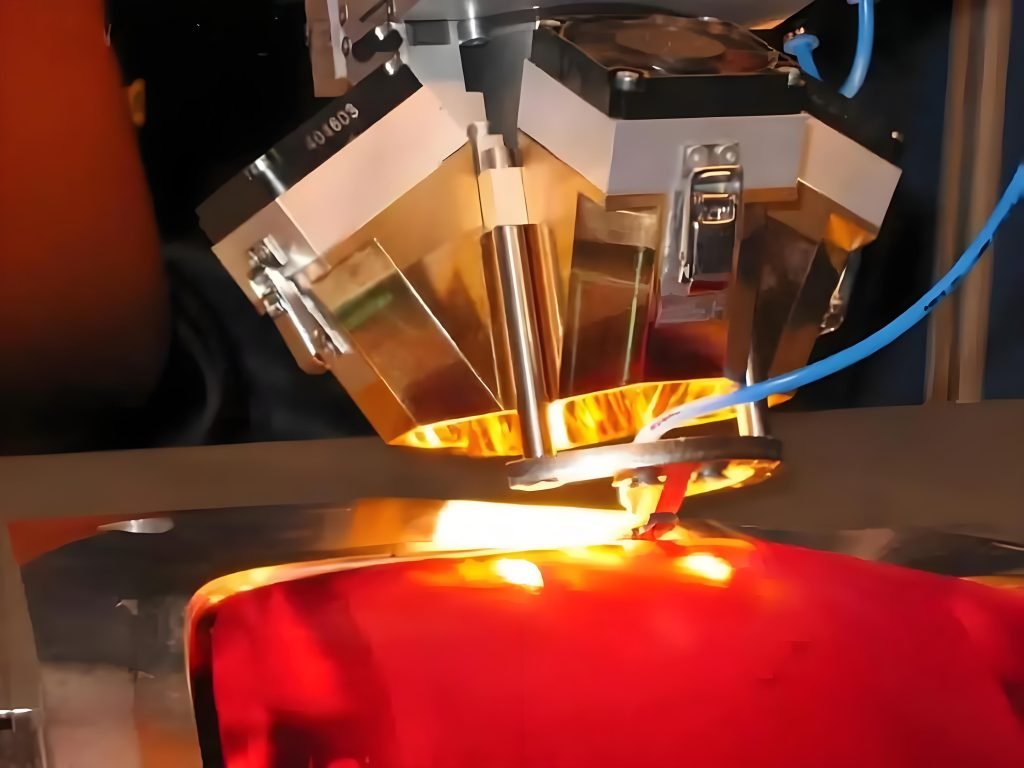

Laser welding

Laser welding uses 980 nm through-transmission with one part transmissive and the other absorptive. It supports complex shapes, minimal particulate, and very fast cycles when tight tolerances and selective colorants are feasible.

Hot gas (convection) welding

Hot gas directs heated air or combustion exhaust at a close standoff to heat surfaces without contact. It’s useful when IR access is limited, though it may need tight tolerances and gas handling.

Mechanical fastening & adhesive/solvent bonding

Fasteners or adhesives remain valid for mixed materials or serviceable assemblies. Weigh added parts, cure time, and long-term stability versus the benefits of a welded bond for durability and speed.

Factors to Consider When Choosing a Connection Method for Plastic Parts

Start by matching material behavior and part form to the available energy delivery and equipment.

Material compatibility and absorption

Confirm your resin pair can weld and check additives or colorants that change absorption. Laser welding needs one part to transmit and the other to absorb at 980 nm, so selective colorants matter.

Part geometry and weld joint design

Evaluate part geometry early. Some processes need linear or rotational motion, optical access, or a flat interface to form a reliable weld joint.

Strength, seal, and cleanliness

Define required joint strength and whether hermetic sealing is mandatory. Hot-plate, vibration, IR, and laser often meet strict leak needs better than fasteners or adhesives.

Plan for flash and particulate control. Vibration can produce debris unless you add flash traps; IR and laser usually reduce particulate and protect internal components.

Production, equipment, and energy delivery

Match production volume to cycle time, automation readiness, and capital cost. Consider emitter selection, safety for laser equipment, and gas use for hot gas welding when tallying total cost of ownership.

How to Select the Right plastic joining techniques for Your Project

Choose a connection path that meets performance targets and shrinks your risk before tooling starts.

Define requirements

Document resin grades, additives, and part thicknesses. Map operating temperatures, fluids, loads, and any regulatory limits so you can match a joining process to your applications.

Shortlist candidate processes

Filter by geometry, energy delivery, and access to the weld area. If a horn or platen won’t fit, consider laser; for round seams, favor spin; for large planar seams, look at hot-plate or vibration.

Design for joining

Specify weld joint features and add energy directors for ultrasonic. Plan flash traps for vibration and optical paths and absorbers for laser. Ensure fixturing applies clamp force without distortion.

Validate before scale

Pilot with worst-case tolerances and measure cycle time components: load, melt, and hold. Capture a process window for melt depth, clamp force, and speed. Run pull, leak, and conditioned life tests so the selected technology proves bond durability at scale.

Conclusion

Decide on a clear path from prototyping to production so your assemblies meet performance targets and budget goals.

Choose laser welding for delicate, complex shapes where low particulate and short cycles matter. Use vibration welding for large planar seams when fast cycle time is key, and select hot-plate welding where hermetic, robust welds are required.

Remember to confirm material and colorant behavior, check that one part can transmit or absorb for laser, and verify fixturing, tolerances, and friction control. Weigh advantages beyond unit cost—faster cycles, less scrap, and fewer consumables—to secure ROI.

Plan validation with realistic applications, lock in equipment and safety needs, and move confidently from learning to production for stronger, repeatable plastics joining results.