Lightweight titanium joints, carbon-fiber forearms, and micron-precise gears—today’s most advanced CNC robot parts are not cast. They are born on the powerful 5 axis CNC robot arm. These machines expertly merge aerospace tolerances with the incredible speed demanded by automation.

This guide will walk you through every step of robotics CNC manufacturing. You’ll learn why advanced machining is the clear choice for creating high-performance robot parts. We will cover the specialized materials and techniques that keep your next robotic project fast, agile, and robust.

Why Choose CNC Machining for Producing Robotic Parts?

CNC machining has fundamental advantages over traditional methods when building a robot. Let’s explore the critical reasons why this process is essential for high-performance automation.

Achieves Micron-Level Accuracy

When you look at CNC robot arm transmissions, they demand extremely tight cumulative pitch error. The high-precision, Swiss-type CNC manufacturing robotics can easily hold tolerances within the single-digit-micron range. This high level of precision is achieved without the need for time-consuming secondary grinding processes.

Integrates Complexity in One Setup

To make assembly simpler and less costly, complexity must be integrated into the part itself. Modern 5 axis CNC robot arm cycles can mill, drill, and create undercuts all in a single setup. This ‘one-shot’ approach eliminates dozens of separate fasteners and joints. Fewer parts mean lower assembly labor costs and less overall inertia in your high-speed industrial CNC robotic arms.

Enables Rapid Iteration for R&D

The best robotic CNC machining services can turn a digital STEP file into a physical part in just a few hours. This speed is vital. It allows your software and AI teams to quickly validate new motion algorithms and robot “gaits” before you start the next design sprint.

Handles Advanced Light-Weighting Alloys

CNC machines are built to cut tough, work-hardening metals that you must consider when designing for robotics. This includes high-grade alloys, such as 7075-T6 aluminum and Ti-6Al-4V titanium. These materials just don’t fuse fully in 3D printing. You get weak points between layers that can break under stress.

Scales Production Effortlessly

The power of CNC lies in its digital foundation, making it versatile for any production volume. A single program can run on a simple 3-axis prototype cell, and then seamlessly scale up to a palletized 5-axis production cell. This flexibility is critical for robotics CNC start-ups. They often need to produce a high mix of different robot variants in low volumes, from tens to a few hundred units.

Key Materials for CNC Robotic Components and Their Applications

Selecting an appropriate material for the application is equally important as the machining. Here are some of the most essential alloys and polymers for robots today to be fast, strong, and long-lasting.

Aluminium Alloys – The Default Light-Weighting Choice

6061-T6 aluminum is excellent for frames, base-plates, and motor housings. It can be easily anodized to dramatically increase the surface hardness. For more demanding applications, 7075-T6 is an aircraft-grade alloy perfect for CNC robot links, offering much higher strength with only a small increase in density.

Stainless Steels – Harsh-Env Durability

If your robot needs to operate in a tough environment, look to 17-4 PH precipitation-hardened stainless steel. It’s ideal for gears, cycloidal discs, or food-grade joints in CNC manufacturing robotics. This material offers a very high yield strength after the correct heat treatment process.

Titanium – Strength-to-Weight Champion

Surgeons often use the Ti-6Al-4V ELI titanium alloy for hip and knee implants. The same alloy is perfect for medium-payload CNC robot arm joints. It is significantly lighter than steel, yet retains comparable strength. Plus, it is completely bio-inert, meaning it won’t react with other materials.

Copper Alloys – Thermal & Electrical Highway

Tellurium copper has exceptional thermal and electrical conductivity. This makes it an ideal choice for making heat sinks to cool servo drives inside industrial CNC robotic arms. It can also be machined using the Electrical Discharge Machining (EDM) process for complex shapes.

Engineering Plastics – Quieter, Self-Lubricating Motion

PEEK plastic is a great choice because it can handle high continuous operating temperatures. It’s often used to replace metal in the vacuum pick-up heads of sensitive CNC automation robots. For timing pulleys, Acetal (Delrin) offers low friction and can achieve an extremely smooth surface finish as-milled.

Carbon-Fiber Reinforced Composites – Ultra-Light Stiffness

Manufacturers can use CNC routing to precisely cut Carbon-Fiber (CF)/titanium stack-ups. This composite approach significantly reduces the mass of effector plates on delta 5 axis CNC robot arms. The lower weight also helps to noticeably boost the robot’s first-mode natural frequency, improving performance.

A Quick Comparison: Common Robotics Materials and Their Properties

Below is a designer’s cheat-sheet that ranks the metals, plastics and composites most frequently programmed into CNC robot workflows. Scan the yield values, weigh the cost bands, and match the last column to your duty cycle before you commit to bar stock.

| Material | Yield MPa | Machinability | Cost Indicator | Key Notes |

| Aluminium (6061) | 275 | Easy | Moderate | Light, corrosion-friendly, good thermal conductivity |

| Aluminium (7075) | 503 | Fair | Moderate+ | Higher strength, still light, aerospace favourite |

| Stainless Steel (17-4 PH) | 1000 | Tough | Moderate+ | High strength, hardenable, vacuum compatible |

| Titanium (Ti-6Al-4V) | 880 | Demanding | Premium | Strength of steel at 60 % weight, bio-safe |

| Copper (Tellurium) | 220 | Easy | Moderate | Star heat-sink, high conductivity |

| Acetal (Delrin) | 65 | Excellent | Low | Low friction, stable, self-lubricating |

| Nylon (PA66) | 75 | Good | Low | Tough, quiet gears, absorbs shock |

| PEEK | 100 | Good | High | Autoclavable, chemical-proof, vacuum OK |

| Polycarbonate | 65 | Good | Low | Transparent armour, impact clear |

| Carbon-fibre Composite | >600 | Slow | High | Ultra-stiff, vibration dead, RF neutral |

Common CNC Robotic Components Made with CNC Machining

Almost every critical part of a modern robot benefits from the precision of CNC. Let’s look at the most frequently machined components.

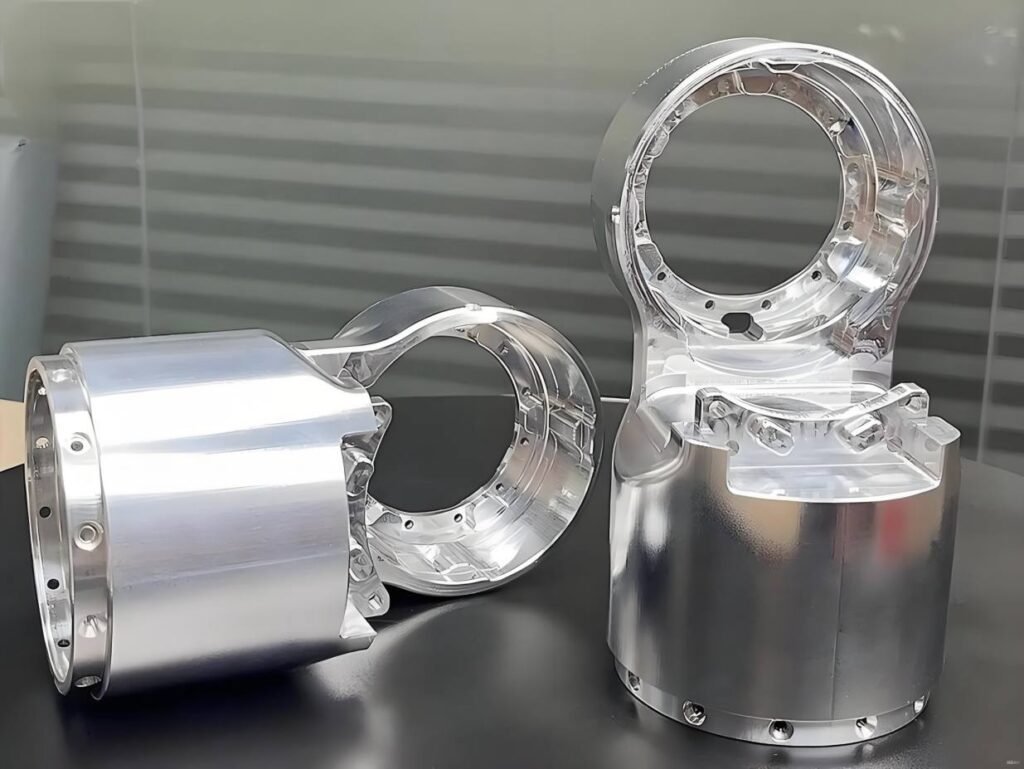

CNC Robotic Arm Links & Rotary Joints

These moving parts are the heart of your robot’s motion and require flawless alignment. That’s why machining all five sides of a rotary joint in one setup is so important. This method keeps the bearing seats perfectly concentric.

This single-setup technique is a vital factor for you to achieve low-backlash performance. This precision is essential for the harmonic drives used in your high-precision robots, ensuring smooth and accurate movement.

End Effectors – Grippers, Suction & Tool Changers

The tools at the end of the arm, or EOAT, must be as light and efficient as possible. You can use a hybrid of lightweight aluminum and titanium. This combination is a great way to significantly lower the overall mass of your End-of-Arm Tooling.

For special features, even mill tiny cooling channels can be milled right into the gripper. This built-in cooling actively stops your vacuum pumps from getting too hot during continuous, fast work.

Sensor Housings & Controller Heat-Spreaders

Electronics create heat, which is bad for precise, long-lasting CNC machining parts for robot company. You can greatly lower the heat in your control units by milling custom copper cooling plates.

This powerful cooling effect is crucial for extending the lifespan of sensitive internal components. It protects sensitive components like motor drivers and processors in your robotic controllers, ensuring stable operation and accurate positioning.

Gearboxes & High-Reduction Cycloids

The gears that transmit power must be machined to micro-tolerances to minimize “creep” or positioning error. Five-axis simultaneous flank milling is a cutting-edge technique that your manufacturer can use.

This method lets you finish the tooth profiles of gearboxes to extremely high accuracy without needing post-hobbing. This is key for you to create the stable, low-creep position loops needed in advanced robotics CNC systems.

Custom Jigs & Fixtures for Robot Cells

For any automated production line to work, the workholding devices must be perfect. CNC machining lets you produce custom modular zero-point fixture plates very quickly, often overnight.

The dowel holes on these plates are held within just a few microns of tolerance. This incredible accuracy ensures that your industrial CNC robotic arms can consistently and identically reload new workpieces every single time without error.

Need micron-accurate joints or jigs? Contact Fecision now to ensure your custom component meets ISO 10218 safety standards.

Tips on Overcoming Challenges in CNC Manufacturing Robotics

Machining robot parts, especially with complex materials, comes with unique hurdles. Here are a few professional tips to tackle common issues.

Thin-Wall Deflection Under Tool Pressure

When you machine very thin walls, the tool can push the material away, which causes a major problem called deflection. This is especially true for strong alloys like Al 7075. To fight this, special tools like variable-helix end-mills should be used and take very light step-downs during the cut.

Manufacturers must also make sure the part is well-supported. Try using a vacuum-chuck to hold it firmly in place. Also, always confirm the wall thickness is right for the part’s total length. This will keep your parts accurate and stop them from bending during the machining process.

Titanium Heat & Tool Wear

Titanium is tough, but it generates too much heat and can quickly destroy your cutting tools. To deal with this, a powerful high-pressure coolant system is needed. Direct this stream right where the tool meets the part.

Manufacturers should also switch to ceramic inserts and use trochoidal cutting paths. Keep the cutting speed moderate. These techniques will significantly extend your tool life compared to using older, conventional machining methods.

Tolerances Stack-Up Across Multi-Part Kinematics

When several parts link together in a robot arm, tiny errors in each piece can stack up into a big mistake. To prevent this, always machine your most important datum features in the same setup on the machine.

Only apply very tight selective fit grades to the surfaces that actually touch and mate with another part. You can safely use a looser, more general tolerance band for all the other surfaces, which speeds up the machining process.

Carbon-Fiber Dust & Delamination

Machining carbon-fiber composite parts requires extra care to manage the dust and stop the layers from splitting, known as delamination. Use down-shear compression mills with a high RPM and a low chip load.

After machining, coat the part with a special surface known as a peel-ply. This prepares the surface so your CNC automation robots can glue-bond the parts securely later on, without needing any secondary sanding or abrasion step.

Batch-to-Batch Surface Consistency for Anodised A-Parts

When your robot parts are going to be anodized, you must achieve the exact same surface consistency every single time. Manufacturers can automate the finish, or Ra value, by using a diamond-cut fly-cutter for a perfect surface.

For clear anodizing, the chemical bath temperature needs to strictly controlled. Keep it within a very narrow window of tolerance. This tight control is absolutely essential to avoid any noticeable color drift between different production batches.

Fecision CNC Machining Services for Your Robotic Parts

Fecision offers premium robotic CNC machining services, specializing in critical parts like harmonic reducer housings and six-axis connectors. Our ISO 9001 and ISO 10218 certified system ensures rigorous dimensional accuracy for all safety-rated components, including collision sensor shells, providing 24/7 industrial automation reliability.

We offer complete solutions, from rapid prototyping to full production, supporting various robotics sectors. Our expertise covers parts for cobots, end effectors, and autonomous systems like AGV drive wheels. We optimize materials and provide DFM feedback to actively reduce design complexity and overall cost.

Additionally, Fecision is equipped with advanced 3-axis to 5-axis CNC machines for complex geometries. Our manufacturing service offers a complete package—fabrication, finishing (like anodizing or heat treatment), and shipping are all available under one umbrella. This ensures fast turnaround times and cost-effective pricing for any robotics manufacturing supply chain’s expedited schedule.

Are you ready for advanced robot development? Submit your 3D design file today to receive rapid DFM feedback and an instant project quote.