One choice is crucial when designing a product. How will you manufacture your parts? The two most widely used techniques are plastic injection molding and CNC machining. They operate in quite different ways, but both are capable of producing outstanding results. Delivery speed, quality, and cost are all impacted by process selection.

You lose time and money if you make the wrong choice. Making the correct choice will increase your efficiency and reliability. Both procedures are described in this guide, along with their advantages and disadvantages. You will know which procedure works best for your project by the end of the process.

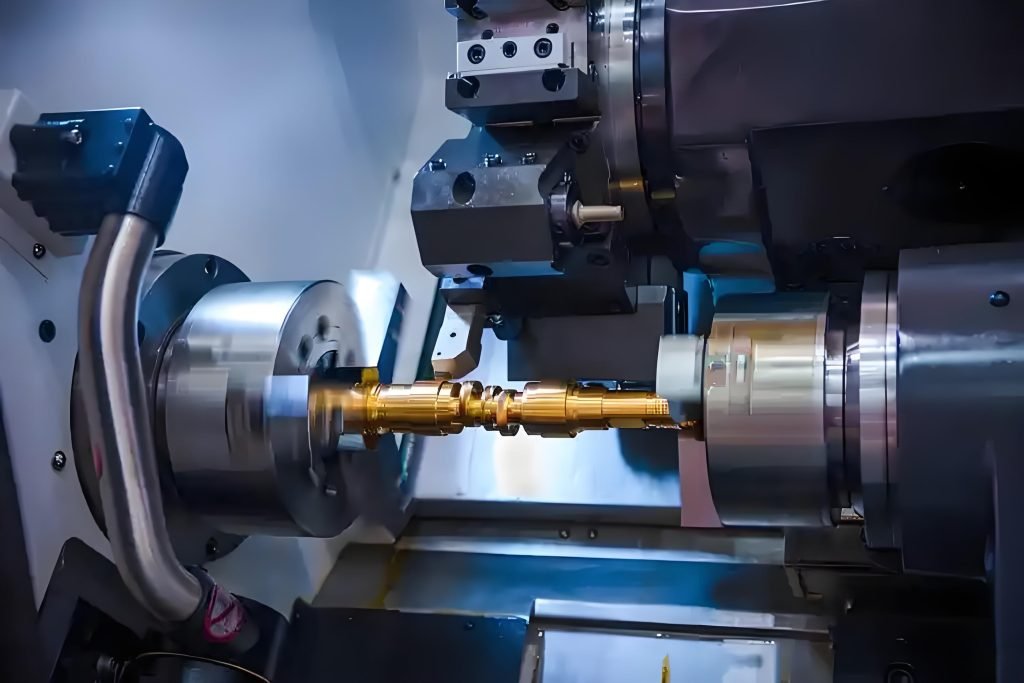

CNC Machining Explained

CNC machining shapes components from solid blocks of metal or plastic with computer-guided tools. Since you don’t need molds, installation is quick and inexpensive. Aluminum, steel, and engineering plastics are among the several materials the process can use. It is ideal for tiny runs, prototypes, and unique parts.

CNC machining offers speed and accuracy in one way, thanks to its strict tolerances, immaculate finishes, and flexibility in design changes.

Injection Molding Explained

By injecting molten plastic into a customized mold, plastic injection molding shapes the plastic. The mold must be designed and built before production, which requires time and money. The process is incredibly efficient once ready, quickly generating thousands of the same components.

At volume, it offers great consistency and a cheap unit cost. Injection molding is the best option for large-scale manufacturing of consumer goods, auto components, and industrial parts.

CNC Machining: Advantages And Limitations

Advantages Of CNC Machining

- No Mold Required: Costly tooling is not required for CNC machining. Production can begin immediately, saving both money and time.

- Wide Material Compatibility: Metals, polymers, and even composites can all be machined with ease. As a result, CNC is far more flexible than molding.

- Great For Prototypes And Small Runs: CNC is the most practical choice when you need a small number of parts or frequently test your design.

- High Precision and Surface Quality: It is possible to achieve smooth finishes and tight tolerances, which are essential for parts that are either mechanical or aesthetically pleasing.

- Complex Geometries: Complex shapes, intricate cuts, and undercuts that are challenging for injection molding to achieve are easily handled by CNC machines.

- Flexible Production: You only need to modify the program if the design changes. Time and money are saved because no new mold needs to be made.

Limitations Of CNC Machining

- High Cost at Scale: Large quantities are expensive because each part requires the same amount of machining time, resulting in a significant increase in overall cost.

- Material Waste: Compared to molding, CNC machining creates more scrap by cutting away excess stock.

- Slower at High Volumes: Machining is slower than molding in mass production; it is effective for small runs.

- Skilled Setup Needed: Expertise is needed for programming and machine setup, particularly for intricate designs.

- Not Ideal for Mass Production: Injection molding is more cost-effective than CNC when thousands of identical parts are required.

Injection Molding: Advantages And Limitations

Benefits of Injection Molding

- Large-Scale Production: Injection molding excels at mass production once the mold is prepared. In a single day, it can deliver thousands of identical units.

- Low Cost Per Part: At scale, each component becomes extremely affordable, but the initial tooling investment is high. For high volumes, this makes the process economical.

- Fast Production Cycles: Molding machines have brief cycle times and operate continuously. High output without the typical machining delays is what that means.

- Excellent Repeatability: Consistency and quality are ensured because every part produced follows the same cycle.

- Flexible Design Options: Multiple colors, textures, and even inserts can be used in the same section. It increases your ability to customize the product.

Limitations Of Injection Molding

- High Upfront Costs: For small businesses, the substantial tooling investment is a barrier.

- Longer Lead Times: Before production begins, mold design and manufacturing can take weeks or months.

- Not Practical for Small Runs: It is expensive to produce a small number of parts because the tooling costs are unjustifiable.

- Costly Design Changes: You may need to create a new mold if you make significant design changes.

- Best Only At Scale: When production reaches thousands or more, injection molding becomes the most valuable process.

CNC Machining Vs Injection Molding: Cost, Speed, And Materials

| Factor | CNC Machining | Injection Molding |

| Cost | Cheaper for prototypes and small runs. No tooling needed. | High tooling cost, but cheaper per part at volume. |

| Speed | Fast to start. Ideal for one-offs and prototypes. | Slower start due to mold-making. Very fast at scale. |

| Materials | Works with metals and plastics. | Limited to plastics and resins. |

| Limits | Expensive at scale. Higher waste. | Long lead times. Not suitable for small runs. |

Choosing The Right Process For Your Project

How do you choose the best process for your project? Begin by asking some important questions:

- How many parts do you need?

- Do you need metal or plastic parts?

- How complex is your design?

- What budget and lead time can you accept?

CNC machining is the best option if you require fifty custom metal parts. Injection molding is the best option if you require 50,000 identical plastic parts. Both procedures work well together for many companies.

First, you can test and prototype your design using CNC machining. After the design is complete, large-scale production is achieved through the use of injection molding. Timeline, material, and volume all influence the best option. By considering these questions, you can lower risk and save money.

Conclusion

You are now aware of the advantages of injection molding and CNC machining. Every technique has a distinct function. Prototypes, custom projects, and small runs are the ideal applications for CNC machining. High-volume, repeatable plastic parts are the ideal candidates for injection molding. The volume, materials, and budget of your project will determine which option is best.

You can save time and money by making an informed choice if you understand both. Fecision offers both mold manufacturing and CNC machining services. We can help you with your project from start to finish, whether you require accurate prototypes or mass production.