The most used manufacturing technique for the mass production of plastic parts is injection molding. Although it is sometimes used for metals and hardly for ceramics, its primary use still comes from plastic product manufacturing. Efficiency, cost savings, and product quality depend on choosing the correct injection molding technique for anything from big automotive parts to tiny electrical components. Making the wrong approach might cause material waste, manufacturing delays, and higher expenses.

The following article provides comprehensive details about injection molding types alongside a simple explanation of selection criteria for your specific requirements.

What is Injection Molding?

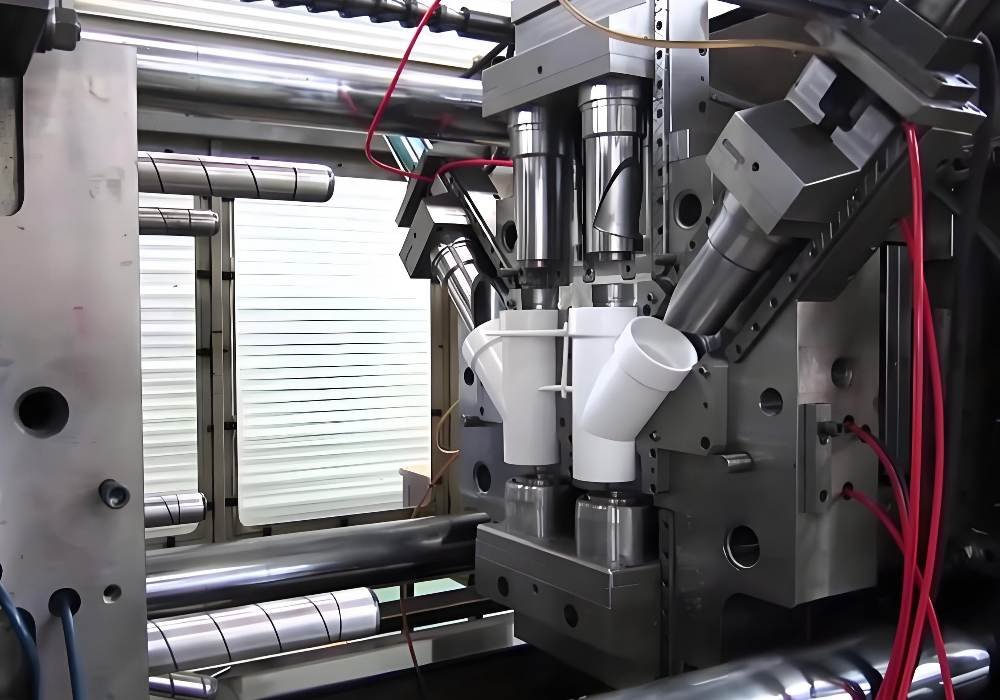

In injection molding manufacturers fill mold cavities with high-pressure melted plastic materials or metals. After the material cools to hardness the mold opens to discharge the finished part. The manufacturing technique achieves maximum efficiency by helping producers create numerous identical items without generating considerable waste during production. The common usage of this method exists across automotive production alongside medical devices and electronics and product manufacturing sectors.

How Does Injection Molding Work?

- Clamping: The two halves of the mold are clamped together.

- Injection: Molten material is poured into the mold cavity in injections.

- Cooling: Cooling causes the substance to solidify into the mold’s form.

- Ejection: The completed component comes out of the mold.

- Repeat: The process begins once more for the next component.

What Are the Different Types of Injection Molding Processes?

The different injection molding types accomplish unique manufacturing objectives. The various methods in injection molding either focus on waste reduction or enhance both product strength and enhance design complexity. There exist several primary categories of injection molding processes that you must understand.

1. Overmolding

The overmolding process unites several different materials during molding to produce one integrated product. The initial step involves molding the substrate base before adding a second material surface layer that normally consists of softer rubber or plastic.

Key Features

- Creates multi-material products.

- Adds comfort, grip, or aesthetic appeal.

- Commonly used with thermoplastics and elastomers.

Applications

- Tool handles (rubber grips over plastic bodies).

- Medical devices (soft-touch surfaces for better handling).

- Automotive interiors (multi-textured dashboards).

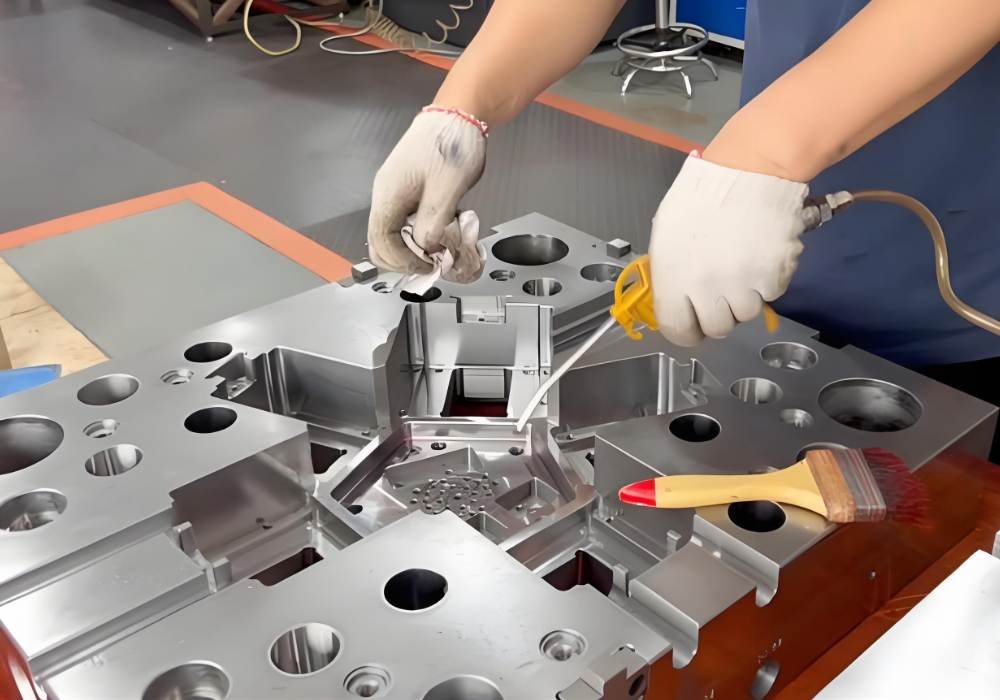

2. Insert Molding

Though it uses plastic around a metal insert, insert molding is like overmolding. The metal insert is placed inside the mold before plastic is injected around it.

Key Features

- Combine metal and plastic in one step.

- Reduces assembly costs.

- Improves part strength and durability.

Applications

- Electrical connectors with metal pins.

- Surgical instruments with metal tips.

- Knobs and fasteners with metal threads.

3. Gas-Assisted Injection Molding

Usually nitrogen, this process pressurizes gas into the mold following the plastic to produce hollow sections inside the part. It preserves strength while cutting material use.

Key Features

- Lightweight parts with strong outer walls.

- Reduced material costs and cycle time.

- Less warping and shrinkage.

Applications

- Automotive components (door handles, dashboard panels).

- Furniture parts (chair armrests, frames).

- Hollow tubes and handles.

4. Metal Injection Molding (MIM)

High-strength and precision small, complicated metal parts are produced using metal injection molding (MIM). The part is sintered by combining powdered metal with a binder, and later removed.

Key Features

- Allows mass production of metal parts.

- More cost-effective than machining.

- High-density, strong metal components.

Applications

- Medical devices (surgical tools, implants).

- Firearm components.

- Gears and mechanical parts.

5. Thin-Wall Injection Molding

This technique produces parts with incredibly thin walls, so lowering weight and material consumption without compromising strength.

Key Features

- Lower material costs.

- Fast production cycles.

- Ideal for mass production.

Applications

- Packaging containers (food and beverage packaging).

- Smartphone cases.

- Medical tubing.

6. Liquid Silicone Rubber (LSR) Injection Molding

This process cures inside a heated mold using liquid silicone rubber. Products ranging from flexible to heat-resistant, or medical-grade, depend on it extensively.

Key Features

- High durability and flexibility.

- Heat, chemical, and UV resistant.

- Biocompatible (safe for human contact).

Applications

- Medical implants.

- Seals and gaskets.

- Baby products (nipples, pacifiers).

What Factors Influence the Choice of Injection Molding Process?

The correct injection molding type depends on several elements. Here are some salient factors:

1. Material Selection

The material selected affects the strength, flexibility, and durability of the finished goods. The intended use dictates the different materials used:

- Applied in consumer goods are plastics (ABS, polycarbonate, nylon).

- Metals ( titanium, stainless steel) are perfect for robust parts.

- Best for flexible and medical uses is silicone and rubber.

2. Production Volume

The number of parts you need determines the best injection molding approach:

- High-volume production → Multi-cavity molds, Thin-wall molding.

- Low-volume production → Single-cavity molds, Prototyping.

3. Part Complexity

The design complexity of your part affects the molding process selection:

- Simple parts → Standard injection molding.

- Complex geometries → Gas-assisted or Overmolding.

4. Strength Requirements

Some products require extra durability or specific strength properties:

- Metal-like strength → Metal Injection Molding.

- Impact resistance → Gas-assisted molding.

5. Cost Considerations

Budget constraints influence material choices and production methods:

- Lower material cost → Gas-assisted, Thin-wall.

- Higher initial cost but durable → Metal Injection Molding.

Conclusion

The selection process for injection molding types enables you to find the appropriate manufacturing method. Quality alongside cost-effectiveness and fast manufacturing happens when you select the suitable technique for your product among metal, plastic or silicone manufacturing.

Before selecting any process you need to analyze each factor including material selection, design intricacy, manufacturing scope and budget parameters Injection molding with the proper process enables better quality results and efficient use of money together with valuable manufacturing resources.

As a professional injection molding supplier, we are proficient in a variety of injection molding technologies. Partner with Fecision to achieve success in your projects.

Frequently Asked Questions (FAQs)

1. Which injection molding procedure provides the lowest overall costs?

Amid all the injection molding types Gas-assisted and thin-wall emerge as cost-effective choices because they need less material and take shorter manufacturing cycles.

2. Which materials are appropriate for injection molding processes?

Production requires ABS and polycarbonate and nylon except stainless steel and liquid silicone rubber as contingent on product use.

3. Which technique should I use when deciding between overmolding and insert molding?

The purpose of the product and material needs will determine whether overmolding or insert molding is best. Overmolding is the better option if your design calls for combining a soft-touch layer with a rigid basis for enhanced grip, comfort, or aesthetics.

Insert molding is the better choice, on the other hand, if your application calls for the integration of a metal component—such as a threaded insert or conductive part—into a plastic body for maximum durability or electrical conductivity.