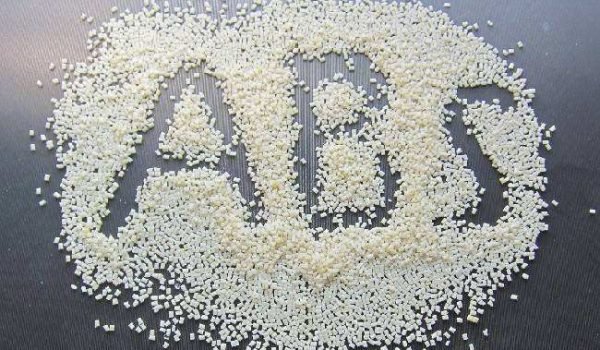

Acrylonitrile Butadiene Styrene, or ABS plastic, is widely used in plastic making. It’s known for being tough, impact-resistant, and affordable. When deciding to use ABS in injection molding, it’s important to think about its properties and the application needed.

Knowing the basics of ABS and injection molding helps make better choices in plastic making. This is true, more so when ABS plastic and injection molding are involved.

Injection molding is a common way to make plastic parts, and ABS is often chosen for this. Its strength and flexibility make it great for many uses. So, manufacturers need to consider the pros and cons of using ABS in injection molding.

They must decide if it’s the right choice for their needs. This involves looking at plastic manufacturing and injection molding aspects.

Understanding ABS Plastic

Acrylonitrile Butadiene Styrene, or ABS, is a plastic material used in many manufacturing applications. It’s made from acrylonitrile, butadiene, and styrene. This mix gives ABS high impact resistance, chemical resistance, and easy processing.

ABS’s chemical makeup makes it strong and versatile. It’s perfect for a wide range of products, from everyday items to car parts. Knowing what ABS can do is key to using it right in manufacturing applications.

What is ABS?

ABS is a plastic material known for its toughness and resistance to chemicals. Its special qualities make it great for many industries, like electronics, cars, and home goods.

Properties of ABS

ABS stands out for its high impact strength, chemical resistance, and easy processing. These traits make it a top pick for manufacturing applications needing both durability and flexibility.

Applications of ABS

ABS is used in many manufacturing applications, including:

- Consumer products, such as appliances and electronics

- Automotive components, such as dashboards and trim

- Industrial equipment, such as pipes and fittings

ABS’s wide use shows its versatility and the value of its ABS properties.

The Injection Molding Process

The injection molding process is key in making plastics. It uses special techniques to create parts. This method is great for making lots of parts quickly and with exact sizes.

Knowing how injection molding works is vital. It helps make production better and ensures products are top-notch. The steps include designing the mold, picking materials, injecting plastic, cooling it, and then taking it out.

Overview of Injection Molding

The first step is designing the mold. This is very important for the product’s quality. The mold must handle high pressure and heat well. Its design affects the whole manufacturing process.

Key Steps in Injection Molding

- Mold design and creation

- Material selection and preparation

- Injection of molten plastic into the mold

- Cooling and solidification of the plastic

- Ejection of the final product from the mold

Advantages of Injection Molding

Injection molding has many benefits. It can make lots of parts at once, control sizes well, and even create complex shapes. These reasons make it a favorite for making plastics, and it’s used in many fields.

ABS in Injection Molding

ABS injection molding is a key process in making things. It’s great because it has a good mix of properties. These include impact strength, heat resistance, and how well it can be molded.

Suitability of ABS for Injection Molding

ABS is a top pick for molding because it has special qualities. It’s strong against impact and heat. This makes it perfect for gadgets, car parts, and medical tools.

Common Uses of Injection Molded ABS

ABS is used in many ways, like:

- Phone cases and computer keyboards

- Dashboards and trim in cars

- Surgical tools and implants

Comparison with Other Plastics

ABS is compared to other plastics like PC and PP. We look at cost, how well it performs, and how it looks. Here’s a table that shows how ABS stacks up:

| Plastic Material | Cost | Performance | Aesthetics |

|---|---|---|---|

| ABS | Medium | High impact strength and heat resistance | Good surface finish |

| PC | High | High impact strength and optical clarity | Excellent surface finish |

| PP | Low | Low impact strength and heat resistance | Fair surface finish |

Factors Affecting ABS Injection Molding

Optimizing the injection molding process for ABS needs careful thought. We must consider temperature, pressure, and cooling time. These factors are key to the quality and properties of the final product. By managing these injection molding parameters, we can make high-quality ABS parts efficiently.

Temperature control is a big part of ABS processing. We need to balance the ABS melt temperature and the mold temperature. Also, we must control pressure and cooling times to get the right part size and production efficiency.

- Temperature control: balancing melt temperature and mold temperature

- Pressure requirements: ensuring sufficient pressure for proper part formation

- Cooling time: optimizing cooling time to minimize cycle time and ensure part quality

By controlling these factors and optimizinginjection molding parameters, we can make high-quality ABS parts. These parts will have consistent properties and look great. This leads to better manufacturing optimization and more efficiency.

| Factor | Optimal Condition | Effect on Part Quality |

|---|---|---|

| Temperature | 180-200°C | Affects part properties and appearance |

| Pressure | 50-100 bar | Influences part formation and dimensional accuracy |

| Cooling Time | 10-30 seconds | Affects part quality and cycle time |

Challenges with ABS Injection Molding

ABS injection molding is a complex process. Several challenges can occur during production. One major concern is injection molding challenges, which can cause defective products and higher costs. Issues like warping, sink marks, and weld lines are known as ABS defects.

To tackle these challenges, manufacturers need to find effective manufacturing solutions. This might mean adjusting how the process is done, improving mold design, or bettering material flow. By understanding and addressing these defects, manufacturers can keep product quality high and costs down.

- Adjusting temperature and pressure settings to optimize the molding process

- Improving mold design to enhance material flow and reduce the risk of defects

- Implementing quality control measures to detect and address issues early in the production process

By using these strategies, manufacturers can beat common ABS defects and make high-quality products. Effective manufacturing solutions are key to staying competitive and meeting customer demands.

The Role of Mold Design

Mold design is key to ABS injection molding success. A good mold design can boost part quality, cut down production time, and save costs. It’s all about material flow, part accuracy, and making the molding process efficient.

When making molds for ABS, knowing ABS’s properties is vital. This includes temperature, pressure, and cooling time. This knowledge helps create injection molding tools for top-notch ABS parts.

Importance of Mold Design

A good mold design makes a big difference in the final product. It ensures parts are precise, smooth, and defect-free. This means better quality and performance for the product. On the other hand, a bad mold can cause problems and lower product quality.

Types of Molds for ABS

There are many molds for ABS injection molding, like single-cavity and multi-cavity molds. Each has its own benefits and needs. The right mold depends on the production size. For example, single-cavity molds are best for small batches, while multi-cavity molds work for bigger ones. ABS molds can make a variety of parts, from simple to complex.

Investing in quality mold design and injection molding tools boosts ABS molding efficiency. This can save money, improve product quality, and make a company more competitive.

Selecting the Right Grade of ABS

Choosing the right ABS grade is key for a successful injection molding process. ABS grades differ in impact resistance, heat deflection, and chemical resistance. These differences affect the final product’s quality.

When picking ABS, think about the application’s needs. Consider the mechanical, thermal, and environmental requirements. The right ABS grade can greatly improve molding performance.

Different Grades Available

There are many ABS grades, each with its own features. You have general-purpose ABS, high-impact ABS, and heat-resistant ABS. The right choice depends on the application’s needs. Knowing the differences is vital for making the best material selection.

Impact on Injection Molding Performance

The ABS grade you choose affects molding efficiency and cost. For instance, high-impact ABS boosts mechanical properties but costs more. General-purpose ABS is cheaper but might lack impact resistance.

By picking the right ABS grade, manufacturers can enhance their molding process. This leads to better products with improved performance and efficiency.

Cost Considerations

When planning an ABS injection molding project, it’s key to look at costs. The injection molding costs depend on several things. These include the price of materials, mold design, how much you plan to make, and the production conditions.

Doing a cost-benefit analysis helps you see if ABS is worth it. You need to think about its benefits like how well it performs, lasts, and looks. Knowing the manufacturing economics of ABS injection molding is vital for smart decisions.

Several things affect ABS pricing:

- Material costs: The price of ABS resin and other materials used.

- Mold design and construction: The cost of making the mold for ABS parts.

- Production volumes: Making lots of ABS parts costs less than making a few.

By looking at these factors and doing a detailed cost-benefit analysis, makers can decide wisely about using ABS injection molding.

| Factor | Description | Impact on Cost |

|---|---|---|

| Material costs | The cost of ABS resin and other materials | High |

| Mold design and construction | The cost of designing and building the mold | Medium |

| Production volumes | The cost of producing large quantities of ABS parts | Low |

Innovations in ABS Injection Molding

The world of ABS injection molding is always changing. New tech and green practices are leading the way. We’re seeing better mold designs, new materials, and smarter ways to make things. These injection molding innovations make ABS molding better and greener.

New uses of ABS technology let us make complex shapes and materials. Also, making things more eco-friendly is a big focus. This means using less energy and cutting down on waste.

These changes help the planet and save money for makers. They also make products better. Here are some ways to make ABS molding greener:

- Using renewable energy sources

- Implementing recycling programs

- Reducing water consumption

By using these injection molding innovations and sustainable manufacturing methods, makers can win in the market. They can also make products that are top-notch and meet customer needs.

Case Studies

Learning from examples is key to understanding ABS in injection molding. Real-world projects show how ABS works in different fields. It’s used in many areas, from everyday items to car parts.

ABS case studies teach us about manufacturing lessons from mistakes. By looking at what went wrong, we can fix our own mistakes. This is vital in injection molding, where small errors can cause big problems.

- Automotive parts, such as dashboard components and trim

- Consumer goods, such as toys and appliances

- Medical devices, such as surgical instruments and equipment

These examples show ABS’s wide use in injection molding. They also stress the role of injection molding applications across industries. By studying these cases, makers can find better ways to work and make quality products.

By learning from the successes and failures of others, manufacturers can refine their techniques and produce high-quality products that meet the needs of their customers.

ABS case studies offer insights into using ABS in injection molding. By using these manufacturing lessons, makers can make better products. This helps them save money and meet customer needs.

Conclusion

ABS injection molding is key in the manufacturing world. It’s versatile and widely used. As technology and green practices grow, ABS’s future looks bright. New ideas and uses will keep it growing and improving.

Summary of Key Points

We’ve looked at ABS plastic and how it’s made. We’ve also talked about what makes ABS injection molding work well. We’ve learned a lot about this important process.

Future Outlook for ABS Injection Molding

The future of ABS injection molding is exciting. Advances in materials, tech, and green practices will lead the way. We can expect more ABS injection molding, future of plastics, and manufacturing trends. This will keep it a vital part of making things today.