From aerospace to marine industries and beyond, bronze parts CNC machining turns this ancient alloy into 21st-century precision components. It can create parts with micron-level accuracy in a remarkably short timeframe. This blend of history and technology is simply amazing.

This guide addresses everything you will need to know in order to be comfortable with this process. You will learn the pros and cons, appropriate alloys, critical techniques, and common applications. We will also examine bronze, brass, and copper, along with helpful design tips to optimize your parts for performance and machining.

What Is Bronze Machining?

Bronze machining is a type of subtractive process in which material is removed from the bronze alloy until the desired shape is achieved through cutting, turning, or milling. Bronze CNC machining is essentially the same, but adds computer control to produce amazing repeatability and micron-level precision for each piece.

Machining bronze is quite efficient. Alloys with additives like lead or phosphorus produce short, brittle chips. These chips break away cleanly, and it helps reduce tool wear and produces a consistent, good surface finish.

Pros and Cons of Bronze CNC Machining

Before CNC machining bronze, know how it performs. These points cover the main strengths and limitations.

Key Advantages

The reasons to choose bronze are compelling, from its speed to its resistance to harsh environments. Let’s examine the primary benefits this alloy offers for your CNC project.

100 % Machinability Index

Bronze alloys, especially with lead, offer the fastest production cycle out of all copper alloys. A perfect machinability score means your total machine-hour bill will be way lower, and speed up your overall production time.

Natural Lubricity

Bronze features a low coefficient of friction. This excellent natural lubricity will result in your finished sliding bronze components, like bushings, not requiring external grease or lubrication from a maintenance perspective.

Salt-Water Immunity

If you are looking for parts for a marine environment, bronze is a great option. In salt water applications such as ships, its good corrosion resistance ensures that fittings have a long life without requiring a lot of protection and maintenance.

Superior Damping

Bronze has superior material damping properties. When used in components such as gears or pump housings, it helps to absorb vibrations, making the machinery much quieter than if it were made from steel or aluminum.

Limitations to Watch

Although the advantages are excellent, there are a few significant challenges to consider when working with bronze. If you work through issues associated with these limitations early, you can avoid complications at a later time in your process.

Higher Material Cost

Bronze billet is generally a pricier starting material. It usually costs more than brass, and often runs much higher than standard low-carbon steel. This factor should be considered in the overall budget for your project.

Work-Hardening Tendency

When CNC machining bronze parts or doing other machining operations, it is important to utilize the correct feed rate. Using an improper feed rate can lead to work-hardening of the surface. This work-hardening can quickly dull your cutting tools and render poor surface finishes.

High Heat Generation

Machining bronze tends to produce a lot of thermal energy, more than when cutting many other harder materials. The excessive heat generally produces adverse effects on tool life and on the dimensional accuracy of the part being machined. Therefore, effective cooling must be used.

Common Bronze Alloys for CNC Machining

Bronze is actually more than a single material; it is a family of alloys that each have specific characteristics. Picking the right grade for your project is an excellent starting point.

Aluminium Bronze (C95400)

This alloy is formed by alloying copper with aluminum, and also with elements like iron. This creates the strongest grade of bronze in the bronze family and is robust and hard-wearing. Thus, it is reliable for high-duty applications in demanding conditions.

Phosphor Bronze (C54400)

Phosphor bronze is a combination of copper and tin, and contains a small amount of phosphorus. As a result, it has excellent fatigue strength and good elasticity. Thus, toughness allows phosphor bronze to be the company’s first choice for parts that require repetitive bending: springs, electrical connectors, etc.

Bearing Bronze (C93200)

Bearing bronze contains tin and lead, and, in turn, it has powerful built-in lubricity. This new low-friction feature often allows parts made of bearing bronze to run smoothly without external grease. Bearing bronze is a great material for bushings and sliding parts for high mechanical loads.

Silicon Bronze (C65500)

Silicon bronze is made mainly from copper and silicon. One of the major features is its ease of weldability and the production of a beautiful mirror-like polish. Silicon bronze is also great for its corrosion resistance and is often used in architectural components and for artistic sculptures.

CNC Machining Techniques for Bronze

Mastering bronze requires specific machine settings and tool choices to maximize efficiency. Follow these proven techniques to get the best surface finish and prolong tool life.

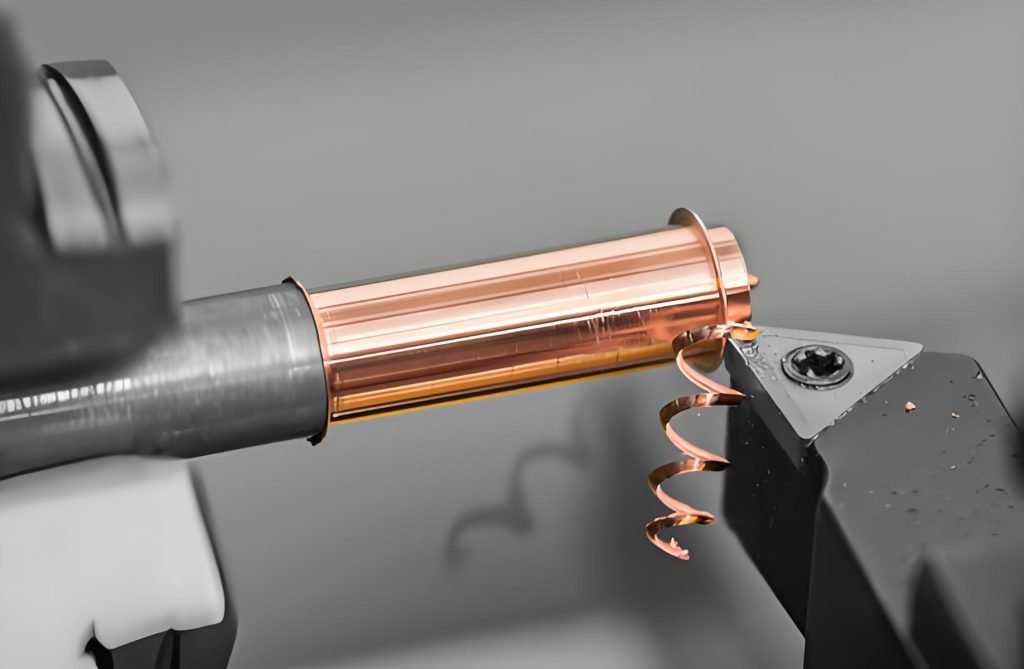

CNC Turning Bronze

Carbide inserts are recommended for turning bronze to achieve optimal results. Operate them at a high surface pre-agreed speed with a moderate feed rate. This method can achieve a fine finish, often suitable for demanding tolerances, without requiring any secondary polishing.

CNC Milling Bronze

When milling, use TiAlN-coated end-mills with a low number of flutes. Keep the chip load light to medium. Always use the climb-milling technique. This action helps to avoid the issue of chips re-welding back onto your freshly cut surface, which is a common problem with bronze.

Drilling and Tapping

To prevent the drill from “walking” at the start, use split-point drills with a steep angle. For creating internal threads, using form taps is highly recommended. These taps eliminate the issue of chip clogging inside the threads, ensuring you get a strong, clean thread every time.

Boring and Broaching

Boring is used to enlarge pre-drilled holes to a precise size, essential for creating accurate bearing seats. Broaching is ideal for machining internal irregular shapes or keyways inside a hole. Bronze’s structure makes it highly suitable for both of these high-precision internal processes.

Coolant and Chip Control

Effective chip removal is crucial. A combination of water-based flood coolant plus a high-pressure through-tool air blast works wonders. This strategy keeps chips clear and can extend your cutting tool life significantly, especially with gummy bronze alloys.

CNC Machining Bronze vs. Other Metals

You have many material options, so knowing how bronze stacks up against common alternatives is vital. Let’s compare CNC machining bronze to brass, copper, and stainless steel to help you make the best choice.

Bronze vs. Brass

Brass generally machines somewhat faster than bronze, but your tools will wear out more quickly. Choose bronze when your part needs to handle a significantly high mechanical load or if it will be constantly exposed to a harsh seawater environment for a long period of time.

Bronze vs. Copper

Copper is the superior choice for high electrical conductivity applications. However, bronze has added strength due to its specific alloy composition. Therefore, bronze generally works better and lasts much longer for moving parts and those facing repeated stress cycles.

Bronze vs. Stainless Steel

Although much stronger than bronze, stainless steel is substantially more damaging to your machining tools. When you look at the long term, bronze often wins out in terms of the total cost per corrosion-free year of service life, especially in non-critical structural applications with less intense forces.

Bronze vs. Aluminum

Aluminum is a much lighter material and easier to machine at higher speeds than bronze. Aluminum is also a very good thermal conductor if that is a requirement. In comparison, bronze is likely a better choice if you need high-strength parts, salt water resistance, or natural lubricity in sliding components.

Key Considerations for CNC Machining Bronze Parts

Successful bronze machining goes beyond just cutting the material; it starts on the drawing board. Following these design and specification guidelines will ensure optimal part performance and manufacturing efficiency.

Design for Machinability

When creating your parts, try to avoid very deep internal pockets and any abrupt geometry changes. Always specify generous corner radii, rather than sharp internal edges. These design choices greatly ease the job for the cutting tool, minimizing stress and significantly reducing overall tool wear during the machining cycle.

Tolerance Realism

While precision is possible, you should be realistic about the tolerances you require. Standard tolerances are easily achievable in routine bronze CNC machining. However, requesting extremely tight tolerances will increase the cost exponentially. Reserve those critical specifications only for key functional areas like precise bearing seats or surfaces that must seal perfectly.

Surface Finish Specification

An as-milled finish is generally considered the industry standard and is cost-effective. If you require a mirror-like polish, you must understand that this needs a separate secondary buffing or finishing process. Make sure to quote and factor in this extra finishing step from the beginning of your project, as it affects the total budget.

Heat & Stress Relief

For high-reliability parts, such as those used in aerospace bronze parts CNC machining, post-machine treatment is necessary. A controlled bake at an elevated temperature helps to stabilize the material’s microstructure. This process effectively relieves any internal stress, ensuring the part maintains its long-term integrity and dimensional stability under load.

Finishing Options

You will also have several options for protective and aesthetic finishing practices depending on your final use. Clear protective lacquer will offer a shinier finish and provide protection. An oil-rubbed patina often offers a darker, more classic look, as does a specified nickel topcoat. These choices cater to visual requirements or critical needs like improved solderability or better surface protection.

Applications of CNC Machined Bronze Parts

Bronze is a versatile metal alloy, making its way into many demanding categories. The strength, lubricity, and corrosion resistance of bronze are what keep it in so many applications across many industries.

Marine Hardware

Bronze is a mainstay in the marine industry. Components like propeller hubs and stern shafts can offer an exceptionally long service life thanks to the inherent corrosion resistance of bronze CNC machining in harsh saltwater environments. This extended life reduces dry-dock maintenance frequency.

Aerospace & Defense

In aerospace, bronze is used for crucial parts like landing-gear bushings, which must adhere to very strict industry and military standards. It has non-sparking characteristics, which is also important for some defence applications, especially in sensitive fuel systems when CNC machining bronze parts.

Industrial Machinery

Bronze is an essential material in heavy industry. For instance, split bearings used in steel-roll lines are capable of absorbing extremely high loads after being precisely made with bronze parts CNC machining. This load capacity is critical for continuous production cycles.

Electrical & Electronics

For electric vehicle (EV) chargers and similar devices, high-force spring contacts are critical. Using phosphor bronze CNC machining provides the necessary combination of excellent electrical conductivity and high fatigue life for millions of connection cycles.

Art, Music & Luxury

Bronze is selected not only for its functionality but also for the beauty and history that quality bronze provides. The warm, rich, gold-like hue of bronze looks great on saxophone keys, high-end watch cases, and custom artistic sculptures. Bronze machining brings precision and timeless quality to luxury and design goods.

Conclusion

Bronze CNC machining is the perfect bridge, combining ancient durability with modern precision manufacturing. It reliably delivers low-friction, strong, and sea-proof components across a wide spectrum of demanding industrial applications, offering exceptional value.

Fecision offers complete, expert Bronze CNC Machining services for complex parts with speed and accuracy. We expertly leverage bronze’s properties—including its high corrosion resistance, especially in marine environments, good strength and durability, and excellent wear resistance with low friction—to deliver superior components for your project.

Our team supports your needs from concept through full production, and we provide engineering resource support for Design for Manufacturability (DfM), which ensures that your bronze components, whether for the maritime or aerospace industries, will meet the highest industry standards of manufacturing every time.

Fecision is the trusted partner, building bronze components using multi-axis CNC and proven metalworking methods. Our ISO 9001 and AS9100 certifications ensure consistent, production-ready parts. We also focus on efficient turnaround and sustainable practices to keep projects on schedule and reduce waste. Discuss what your specific bronze component needs are today, and let us accelerate your production timelines!