Knowledge Center

Delrin CNC Machining: The Comprehensive Guide

What is Gear Machining? Expert Guide to Processes & Materials

Is Delrin the Same as Acetal: Key Differences Explained

All Articles

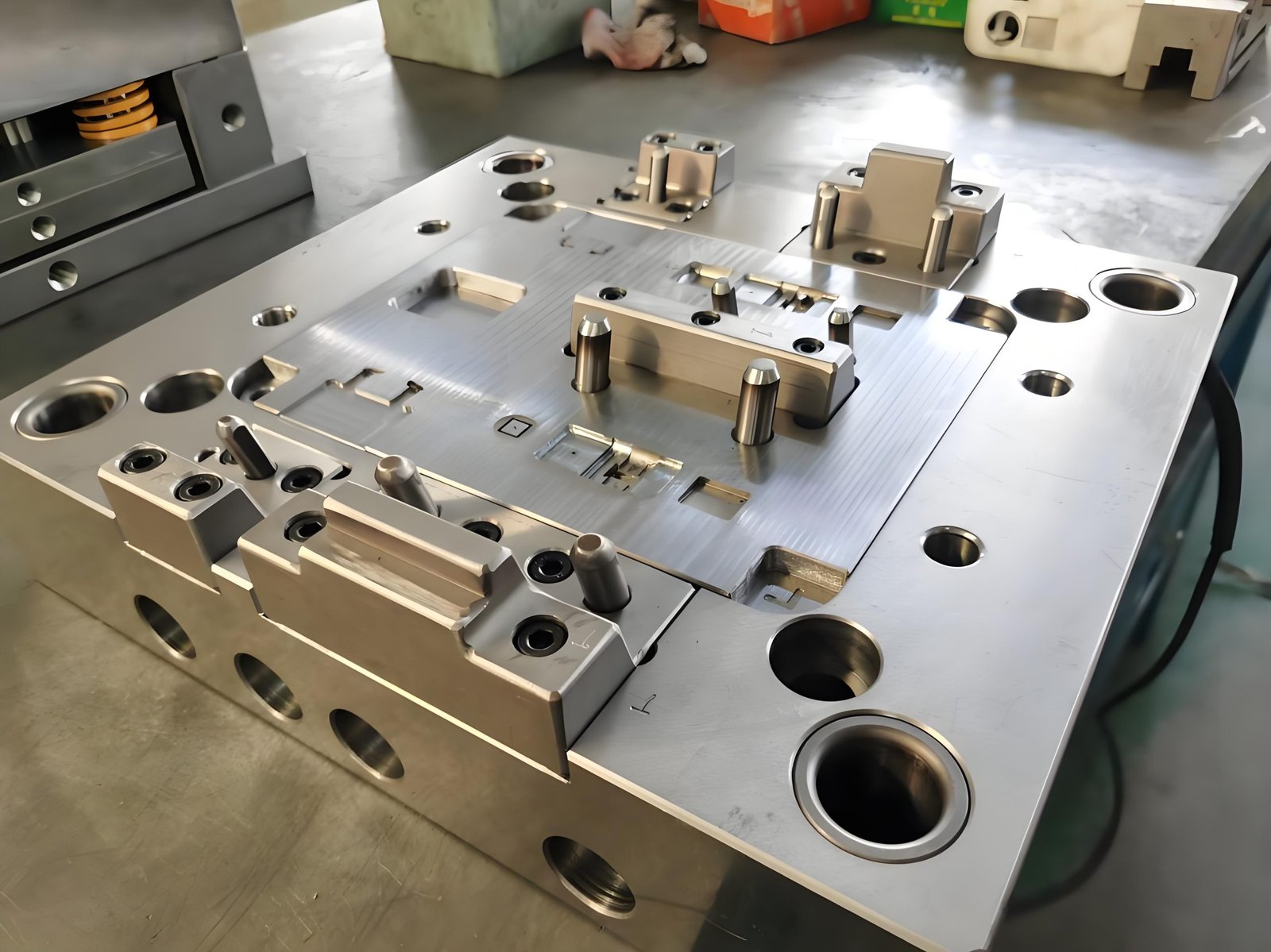

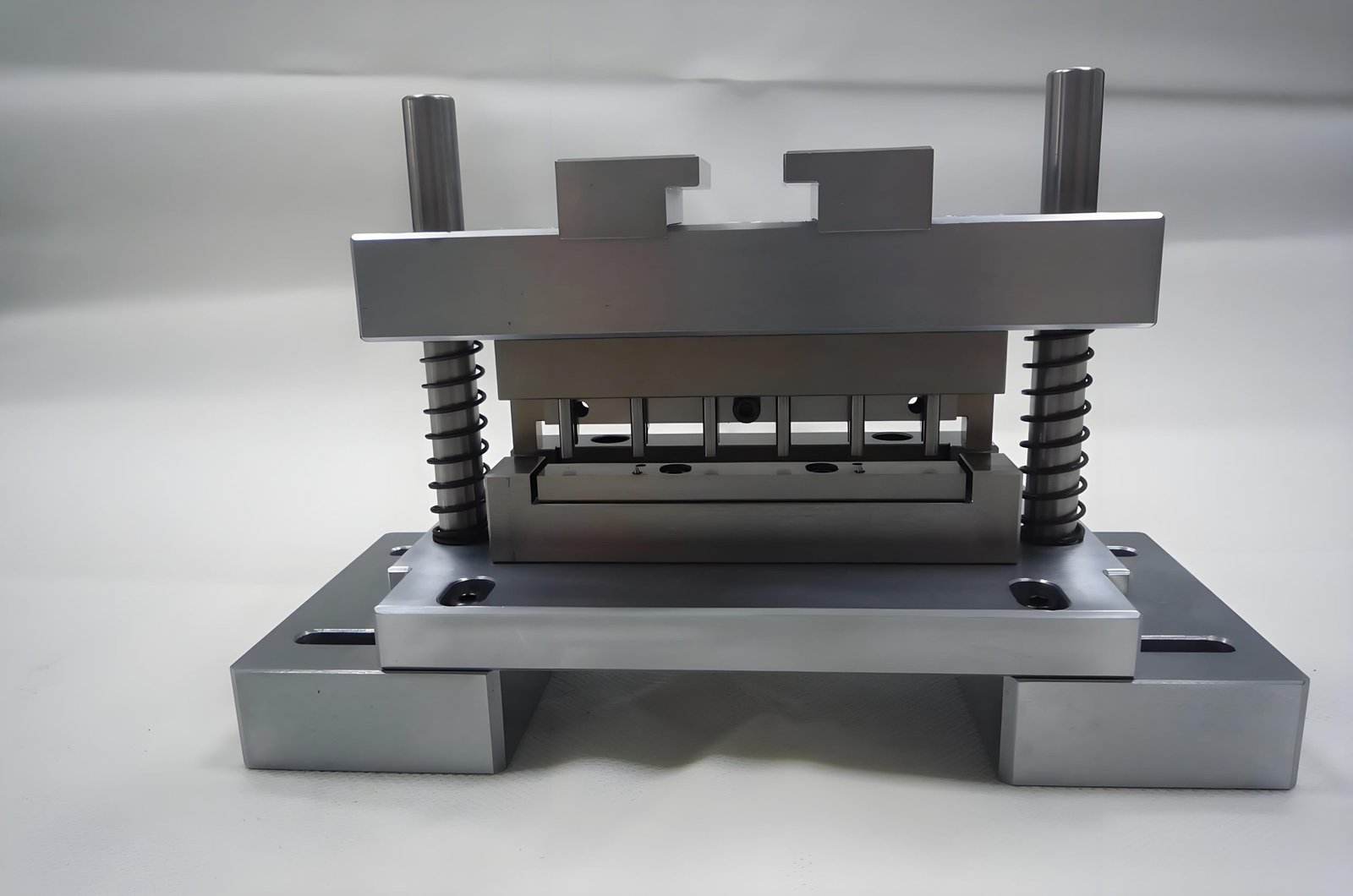

What Are Injection Molding Inserts and How Do They Work?

Do you know what injection molding inserts are? Here you will learn how these inserts work to improve design, functionality, and efficiency in molding.

What Is the Return Pin for Mold?

What is a return pin for mold? Explore its function in return pin injection molding, different types, material choices, and why quality mold components are essential for efficient production.

Injection Molding Slider vs Lifter: What Are the Differences?

What are the differences between injection molding sliders and lifters? Expert insights for better mold design and performance. You won’t be confused after reading!

The Manufacturing Process of Electrical Connectors

Discover the world of electrical connectors! Learn about how electrical connectors are made, including the basic raw materials, and the advanced processes like injection molding and stamping.

Plastic Injection Mold Tool Steel: Which One Suits Your Needs Best?

Confused about which injection mold tool steel to use? Discover the best options for durability, cost, and performance, customized to your project’s needs.

Role of Locating Ring in Injection Molding: What You Should Know

Do you know why a locating ring in injection molding is used and why it is essential for precision? Discover its role in ensuring accurate mold alignment.

The Injection Mold Cooling System: Function, Design, and Importance

Maximize efficiency with the right Injection Mold Cooling System. Learn key design tips, components, and maintenance for top performance.

Injection Molding Uncovered: What is a Sprue Bushing?

Learn how the right Sprue Bushing improves injection molding flow, cycle time, and part quality. Boost performance with expert tips.

Guide Pins in Molds: Their Indispensable Purpose Decoded

Guide pins are the driving force behind seamless injection molding. Learn how they ensure precise alignment, reduce wear, and improve operational efficiency.

The Crucial Role of Core Pins in Injection Molding: An In-Depth Look

Unlock the secret to perfect plastic parts! Discover how core pins, the unsung heroes of injection molding, craft intricate details and hollows. Learn about materials, custom vs. standard, and find the best manufacturer for your precision needs!

Choosing the Perfect Metal for LSR Injection Mold: A Comprehensive Guide

Discover the best metals for your LSR Injection Mold. Ensure durability, precision, and cost-efficiency with expert material selection tips.

Ejector Pin vs Ejector Sleeve: Unraveling the Key Distinctions in Injection Molding

Discover the key differences between ejector pins and ejector sleeves in injection molding and how they impact part quality, cycle time, and tooling.

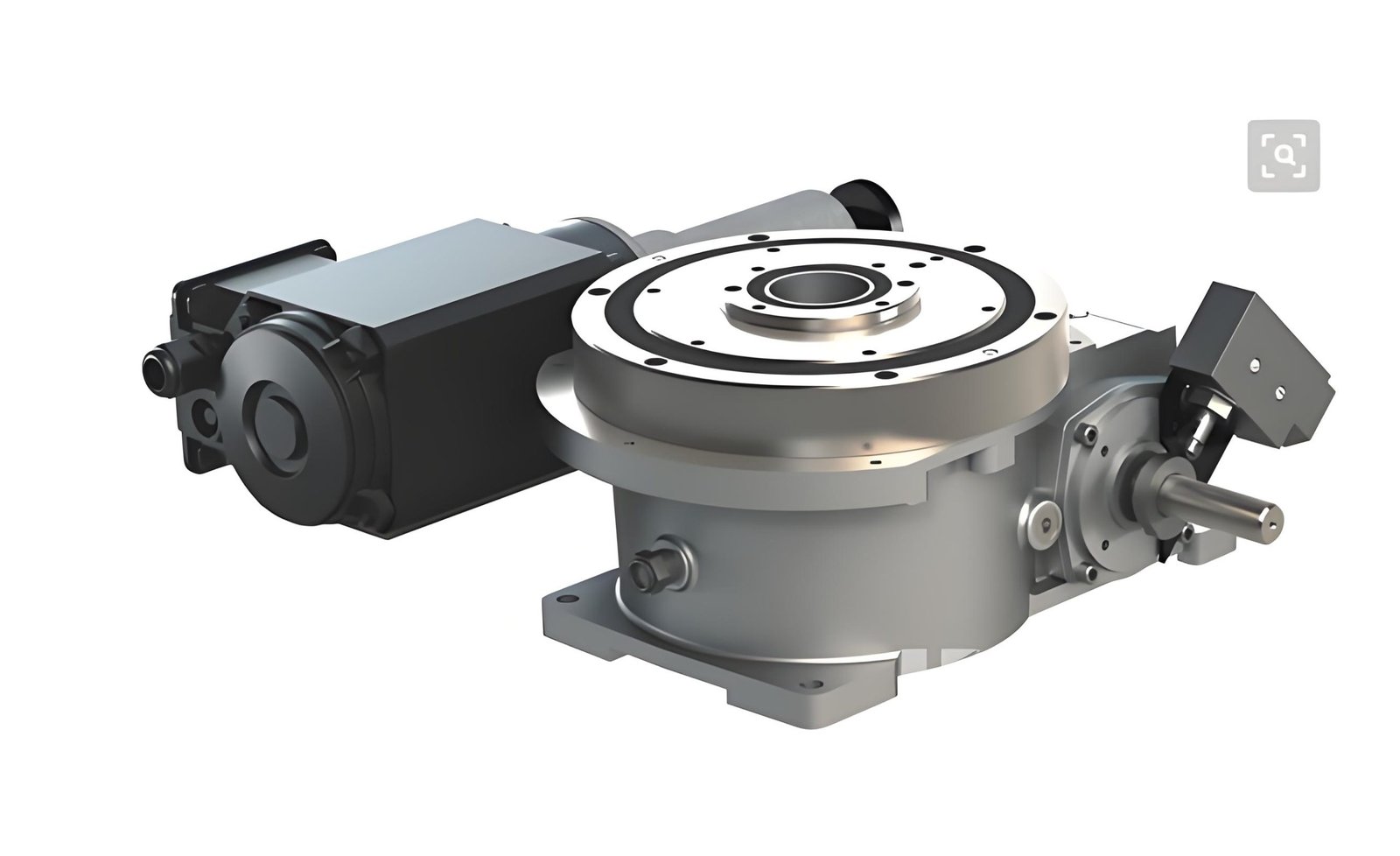

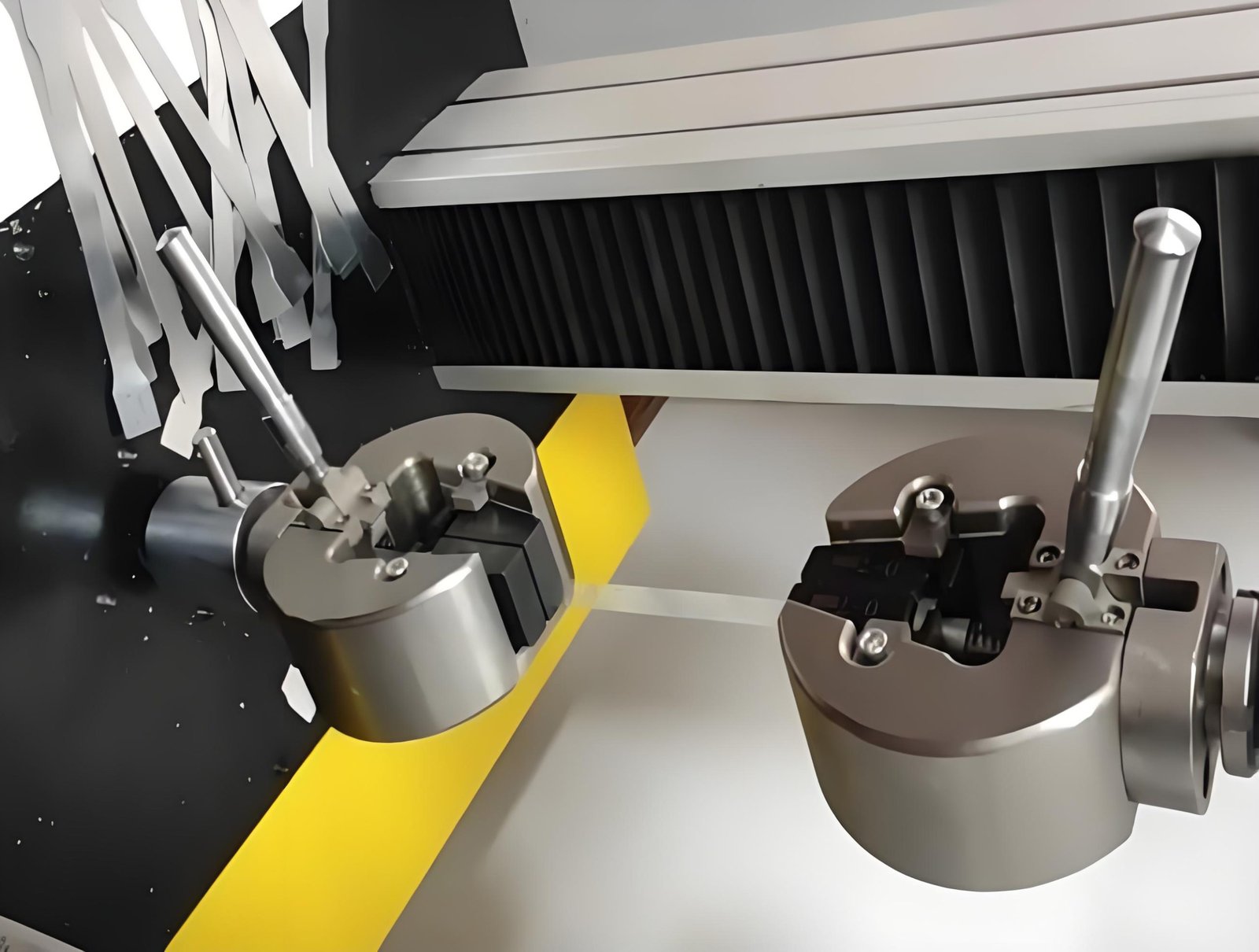

What Is a Power Chuck? A Complete Guide to Types, Uses & Benefits

A power chuck is an advanced work-holding device designed for CNC lathes and automated machining systems. It is a versatile tool with various types available for selection. What is a power chuck indeed? Find the answer together!

Hydraulic vs Pneumatic Fixtures: A Comparative Guide

Hydraulic vs Pneumatic fixtures: Discover which is best for your manufacturing. Get high precision or rapid speed, tailored to your project needs.

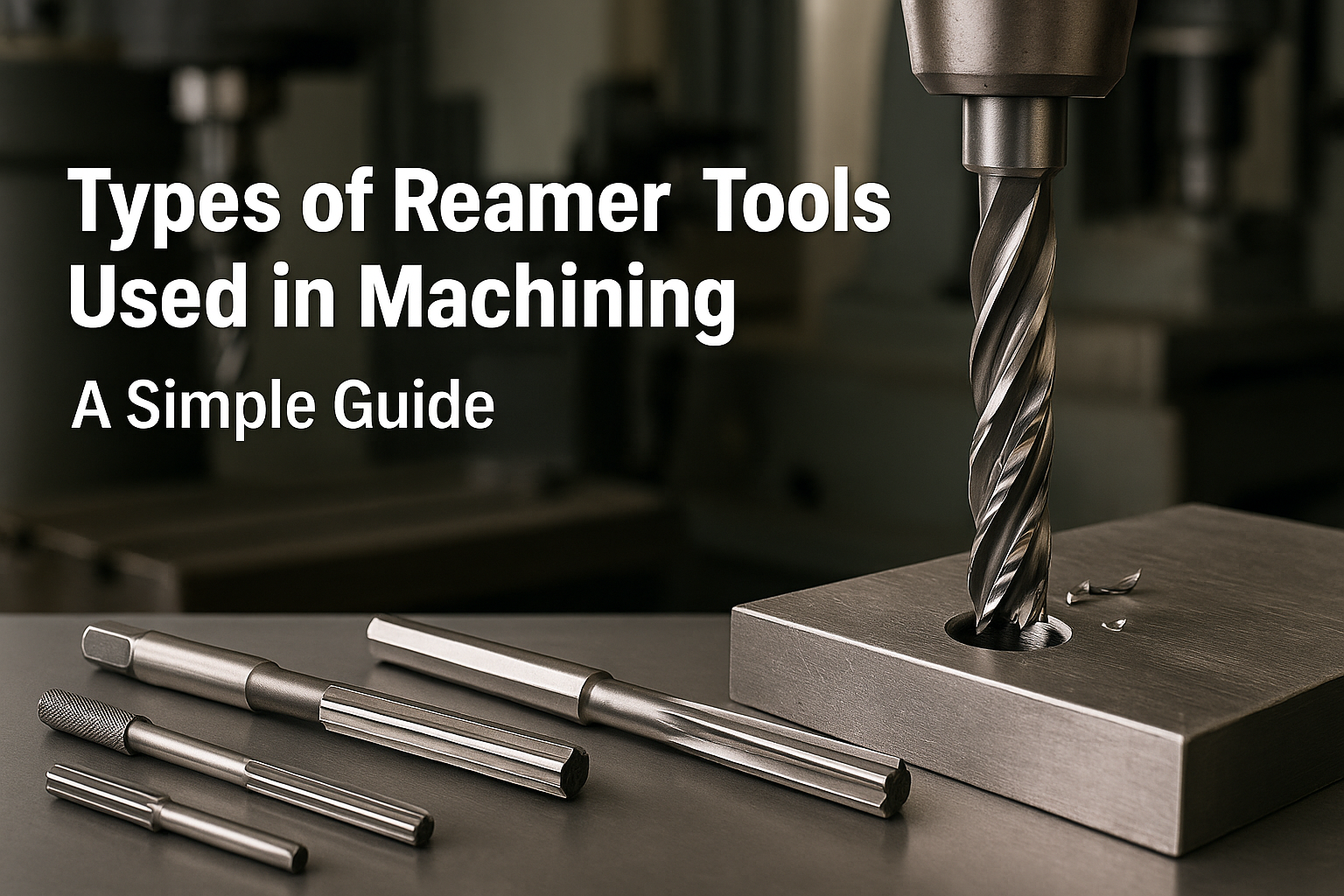

Types of Reamer Tools Used in Machining: A Comprehensive Guide

Discover the types of reamer tools used in machining, from hand reamers to specialty tools. Learn how they work and how to choose the right reamer for your project.

Types of CNC Machine Tools: Your Guide to Precision Manufacturing

Explore CNC machine tools: milling, lathes, EDM, and more. Learn their uses and how to choose the best for precision manufacturing.

Hydraulic Chuck Clamping Pressure: Determine the Right Pressure

Learn how to determine the right Hydraulic chuck clamping pressure for your machining needs. Discover key factors and consequences of incorrect pressure.

What Is the Difference Between Jigs and Fixtures?

Understand the fundamental differences between jigs and fixtures in manufacturing. Learn how these tools provide guidance for tools or hold workpieces for accurate operations.

How to Design Jigs and Fixtures: A Complete Guide for Precision Manufacturing

Master jig and fixture design for precision manufacturing. Learn how these tools address key issues when working with advanced machines like CNC machining.

What Is A Rivet: Definition, Types, Working process and Applications

Learn about Rivets: Definition, types, working process, and applications. Choose the right rivets for your projects with our expert guide.

What Is A CNC Milling Machine? A Comprehensive Guide

Get to know the cnc milling machine: its components, working principle, and advantages. Optimize your manufacturing process with precision.

Introduction to Fixtures and Jigs: Essential Workholding Device

Discover the ultimate guide to Fixtures and Jigs, essential workholding devices for precision engineering. Learn about types, design, and benefits.

Top 10 Types of Machining Process

Take advantage of modern manufacturing by viewing this guide to the top 10 CNC machining processes today! Find out about all types of CNC machining and the capability to create high-precision parts.

Ductility vs Malleability: What’s the Difference?

Discover the key differences between Ductility vs Malleability and understand their importance in material science. Learn how they’re measured and their applications.

A List of Injection Molding Gate Types for Optimal Part Design

Learn how to choose the right injection molding gate type to optimize your part design! This guide covers different gate types, their pros, cons, and how to select the best one for your project to reduce defects and costs.

Plastic Manufacturing Process: A Full Guide from Material to Finished Part

Ready to produce your plastic parts? This guide describes the main plastic manufacturing process and helps you choose the most appropriate one for your project, maintaining precision and quality.

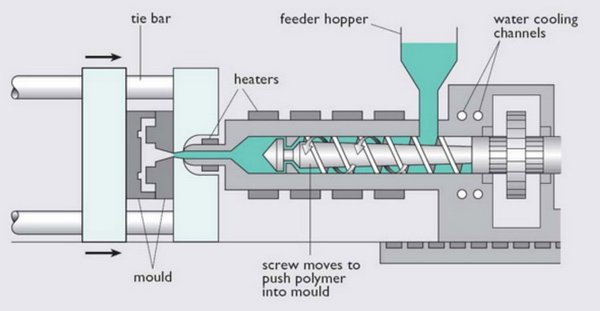

Injection Molding Parameters: A Complete Guide

Get perfect plastic parts every time. This guide to injection molding parameters will help you optimize settings like temperature, pressure, and cycle time to improve quality and productivity.

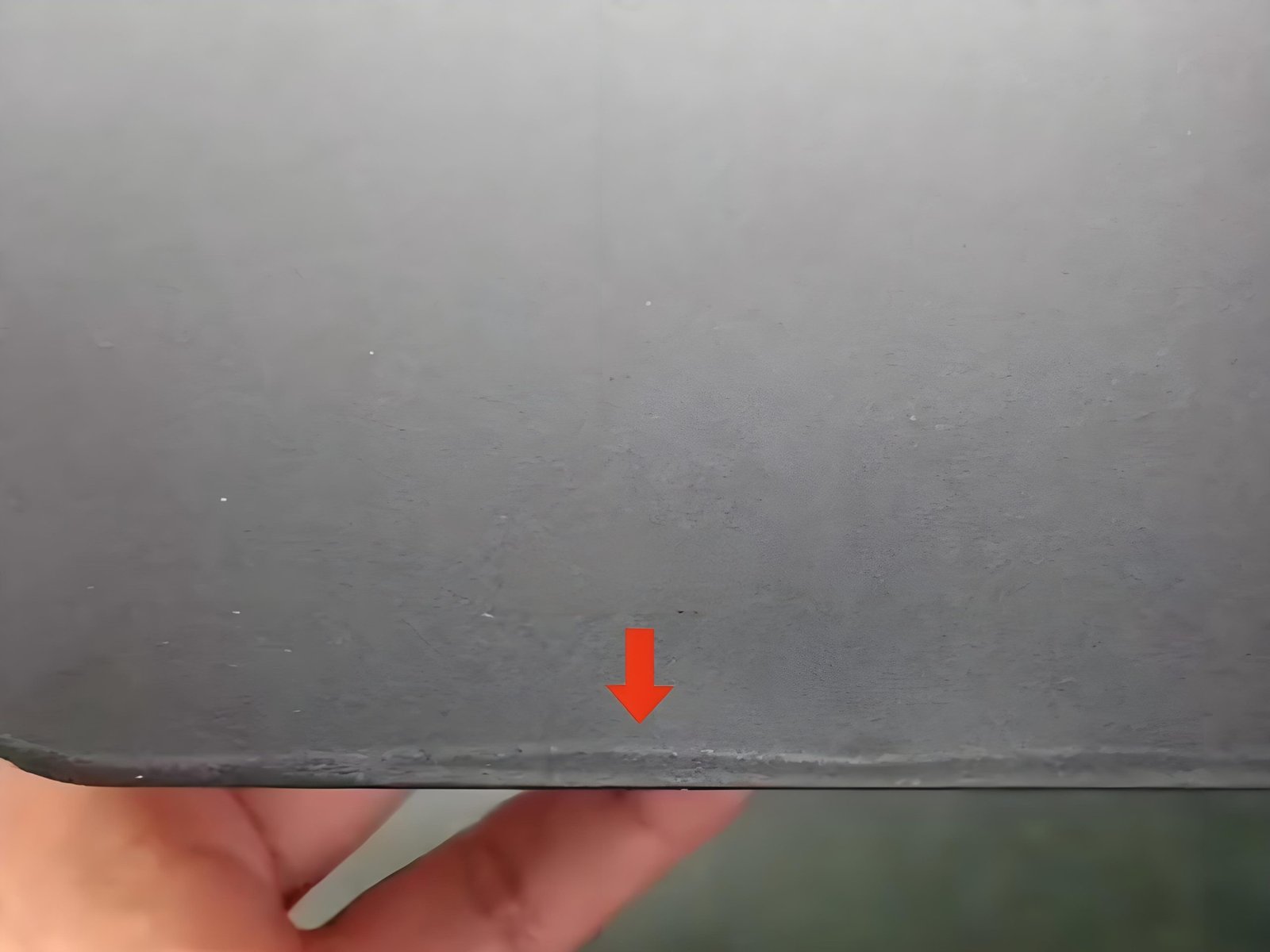

Splay In Injection Molding: Causes, Fixes, And Prevention

Discover what splay in injection molding is, what causes it, and practical fixes and prevention tips to produce defect-free parts.

Injection Molding vs Compression Molding: Which Is Right for You?

Learn the key differences between injection molding and compression molding. Discover cost, process, and best use cases for projects.

A Guide to Glass Filled Nylon Injection Molding: Definition, Advantages, Types and Process Guidelines

Glass filled nylon injection molding uses nylon with glass fiber. Discover what it is, its benefits, types, process tips and more here.

What Is Gating System in Casting: Design, Types, and Key Principles.

A gating system in casting guides molten metal into the mold, ensuring smooth flow and minimizing defects. Learn about its types, key components, and design principles.

How to Improve Color Consistency in Injection Molding: 5 Best Ways

Learn 5 effective ways to maintain perfect color consistency in injection molding. Solve common challenges and ensure high-quality, uniform results.

Understanding the Phases of Injection Molding Cycle

Injection molding cycle involves several key phases. This guide explains each step, factors that affect cycle time, and practical ways to improve efficiency and part quality.

What Are Ejector Pin Marks: Impact, Causes, & Prevention.

What ejector pin marks are in injection molding? Explore their causes, effects on product quality, and proven prevention methods.

What Is Rapid Injection Molding: Definition, Procedure & Benefits

Learn what rapid injection molding is, how the process works, the materials used, and why it is beneficial to create prototypes and low-volume parts.

What Is Gas Assisted Injection Molding?

Do you want to create plastic parts that are strong but lightweight? Gas assisted injection molding can create them, reducing your material cost and allowing for your design to be more flexible.

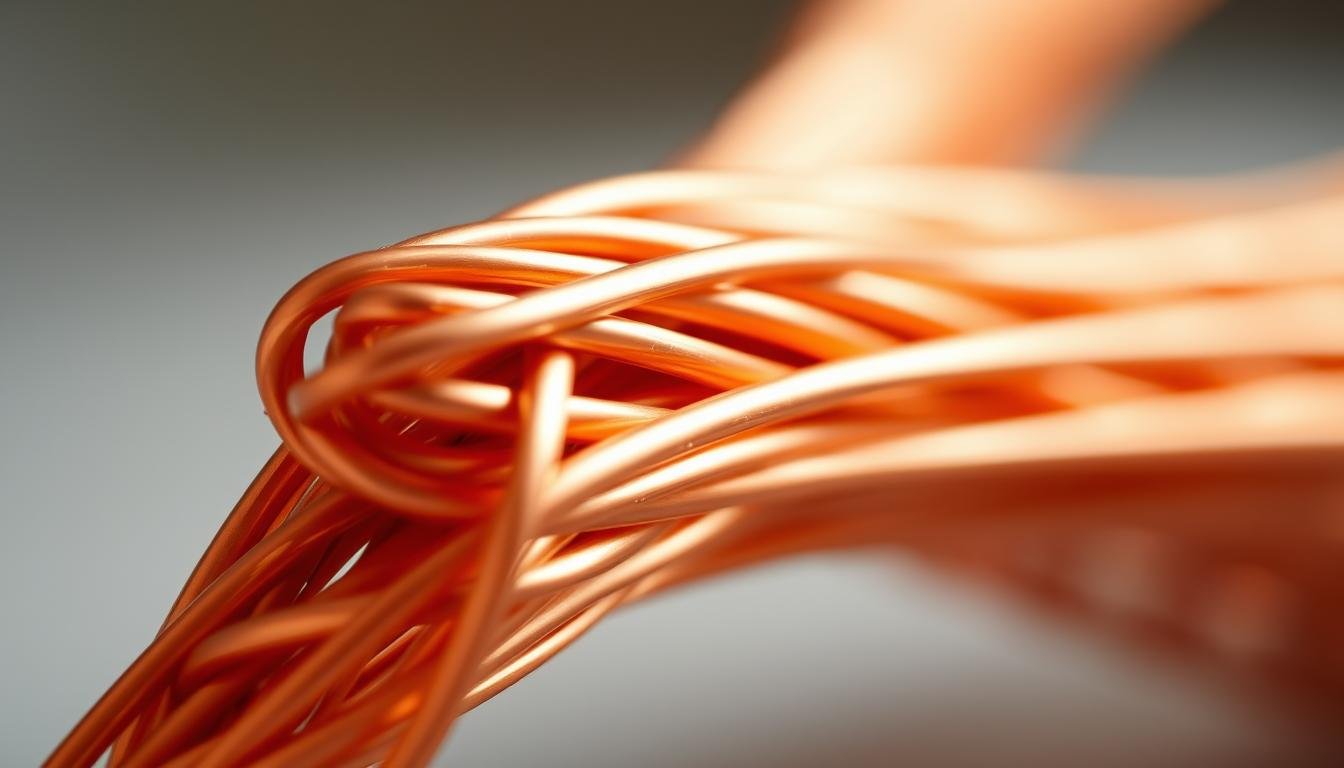

Why Copper is a Conductor: Facts and Applications

Is copper a conductor? Yes, and it’s widely used in electrical connectors and systems. Explore the factors affecting its conductivity and its benefits.

Is Aluminum Conductive? Facts on Electrical Conductivity

Learn the facts: is aluminum conductive? Explore how aluminum’s conductivity compares to other metals and its uses as an electric conductor.

Is Tin Magnetic? Exploring Tin’s Properties

Explore is tin magnetic, its properties, and applications in manufacturing, including the role of tin purity and alloys.

Is Silver Magnetic? Facts & Industrial Applications

Discover if silver is magnetic and learn how to test its magnetism. Understand the factors affecting silver’s non-magnetic properties and its industrial applications.

Is Bronze Magnetic? Uncover the Facts and Uses

Is bronze magnetic? Uncover the facts about bronze’s magnetic behavior, its alloys, and applications in manufacturing.

Understanding Nylon Melting Point for Injection Molding

Understand the nylon melting point and its impact on your injection molding projects. Compare high and low melting point nylon and their uses in various industries.

Understanding Polycarbonate Melting Point

Learn about polycarbonate melting point, its significance in manufacturing, and how it affects the performance of your final products.

Teflon Melting Point: Factors, Types, and Applications Explained

Learn about the teflon melting point, factors affecting it, and how to melt Teflon materials. Compare different types and their applications in manufacturing.

Tensile Strength: Definition, Significance, and Material Examples

Discover the importance of tensile strength in material selection. Learn its definition, significance, calculation, and types, as well as factors affecting it and test methods.

HDPE Melting Point: What You Need to Know for Manufacturing

Understand the hdpe melting point and its role in industrial applications. Explore its differences with LDPE, factors influencing its melting point, and its uses.

Polypropylene Melting Point: Key to Effective Plastic Manufacturing

Understand polypropylene melting point and its role in effective plastic manufacturing processes, including injection molding.

Alloy 42 vs Kovar: Choosing the Right Alloy for Your Needs

Alloy42 vs kovar: Understand the key differences in chemical composition, thermal properties, and uses. Choose the right alloy for your manufacturing needs.

Let's Start!

Together, we can make something remarkable!

Let us turn your vision into reality. Provide us with your project details, and we’ll create a customized proposal designed specifically for you.