Have you ever wondered how complex machinery and precision engineering components are manufactured with such accuracy? The answer lies in the intricate details of machining processes, particularly in the creation of blind holes.

Industries such as aerospace, automotive, and electronics rely heavily on blind hole machining for various applications, from assembly to aesthetic design. As we explore the world of blind holes, you’ll discover their significance in engineering design and the precision required in their creation.

What Are Blind Holes in Machining?

In machining, you often encounter holes that don’t pass through the entire material. These are known as blind holes, a crucial feature in many machined parts.

Definition and Basic Characteristics

A blind hole is a cavity that is drilled or machined into a part but does not extend through the entire thickness of the material. Blind holes are used for various purposes, including accommodating fasteners or providing a recess for other components. The depth of a blind hole is typically specified, and it’s essential to control this depth accurately to ensure the hole serves its intended function.

Blind Hole vs. Through-Hole: Key Differences

The primary distinction between a blind hole and a through-hole lies in their penetration depth. A through-hole passes completely through the material, whereas a blind hole terminates at a specified depth within the part. This difference affects the machining process, tool selection, and the final product’s structural integrity and appearance. For instance, blind holes often require specialized taps, known as bottoming taps, due to the challenge of chip evacuation. In contrast, through-holes can typically use standard taper taps.

Functions and Applications of Blind Holes

Blind holes play a crucial role in modern machining, offering numerous benefits in design and engineering applications. You can leverage these advantages to enhance the functionality and efficiency of your projects.

Structural Benefits in Engineering

Blind holes provide significant structural benefits, particularly in precision engineering. They enable the creation of complex internal features that enhance the overall strength and durability of components without compromising their integrity.

Aesthetic Advantages in Design

In addition to their functional benefits, blind holes also offer aesthetic advantages. They allow designers to create sleek, minimalist designs by concealing fasteners and other components, resulting in a cleaner and more visually appealing product.

Space Optimization in Compact Designs

Blind holes are particularly useful in compact designs where space is limited. By not requiring clearance on both sides, blind holes enable more efficient use of space, making them ideal for applications in electronics, aerospace, and other industries where miniaturization is critical.

You can utilize blind holes to mount components in limited spaces, reduce weight while maintaining structural integrity, and create multi-level mounting surfaces within a single component.

Design Considerations for Blind Holes

When designing blind holes, several key factors must be considered to ensure optimal performance and manufacturability.

Depth-to-Diameter Ratio Guidelines

The depth-to-diameter ratio is a critical factor in blind hole design. A higher ratio can lead to difficulties in machining and may result in reduced accuracy. Generally, a ratio of 3:1 to 5:1 is considered optimal, depending on the material and machining process used.

Material Selection Impact

Material properties play a significant role in blind hole design. The machinability of the material, its strength, and its surface finish requirements all influence the design. For instance, harder materials may require specialized tooling, while softer materials might be more prone to damage during machining.

Tolerance and Precision Requirements

Tolerance and precision are crucial in blind hole design, particularly due to the challenges in controlling depth. Proper tolerance specification is essential based on the functional requirements of the blind hole. Modern CNC machining has improved achievable tolerances, but balancing precision needs with practical manufacturing capabilities remains key.

How To Drill a Blind Hole

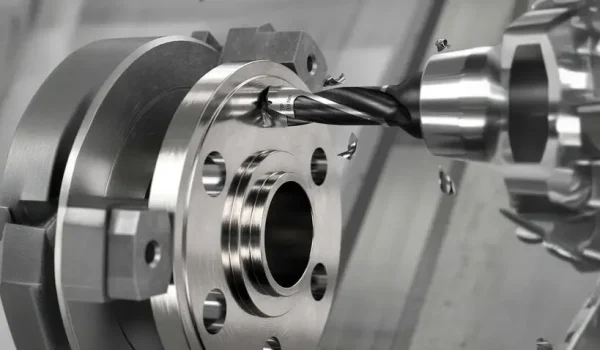

Selecting the Right Tools and Equipment

Choosing the correct drill bit and equipment is crucial for drilling blind holes. You should select a drill bit that is appropriate for the material you are working with, whether it’s metal, wood, or another substance. Using the right tools ensures that the hole is drilled accurately and cleanly.

Marking and Setup Procedures

Before you start drilling, it’s essential to mark the spot where you want to create the blind hole. Use a center punch to create a small indentation, which will help guide the drill bit and prevent it from wandering. Ensure that your workpiece is securely clamped to prevent movement during drilling.

Drilling Technique for Optimal Results

When drilling a blind hole, start slowly to ensure accuracy and prevent the drill bit from drifting. Apply cutting lubricant when drilling through metal to keep the drill bit cool and prevent overheating. Use a peck drilling technique for deep holes to improve chip evacuation and maintain hole quality. Monitor your drilling speed and feed rate according to the material and hole size.

Managing Depth and Accuracy in Blind Hole Machining

Accurate blind hole machining requires precise control over depth and alignment to ensure the quality of the final product. When drilling blind holes, maintaining the correct depth and ensuring the hole is perpendicular to the surface are critical for the structural integrity and functionality of the component.

Depth Control Methods

You can achieve precise depth control using a drill press, which is equipped with a depth indicator. This feature allows you to set the desired depth and ensures that the drill bit does not exceed it. The drill press also helps in maintaining the drill bit’s perpendicularity to the workpiece, reducing the risk of angled holes.

Ensuring Perpendicularity and Alignment

To ensure perpendicularity and proper alignment, you can use fixtures, jigs, and alignment tools. These tools help in setting up the workpiece correctly and maintaining the drill bit’s alignment during the drilling process. Additionally, using squares and indicators during setup and drilling can verify that the drill is perpendicular to the workpiece, thus enhancing the accuracy of the blind hole.

Chip and Debris Management

Managing chips and debris is a critical aspect of drilling blind holes, directly impacting the accuracy and finish of the hole. When you drill a blind hole, the chips and debris that accumulate can compromise the quality of the hole if not properly managed.

Evacuation Techniques During Drilling

During the drilling process, effective evacuation techniques are essential to remove chips and debris. You can improve chip evacuation by using the right drill bit geometry and applying appropriate drilling parameters, such as pecking cycles, to help clear chips from the hole.

Post-Drilling Cleaning Methods

After drilling, thorough cleaning is necessary to remove any remaining debris. You can use compressed air or specialized hand-held hole cleaners that blow compressed air into the hole while simultaneously vacuuming out the debris. The choice of cleaning method depends on the material and the specific requirements of the hole.

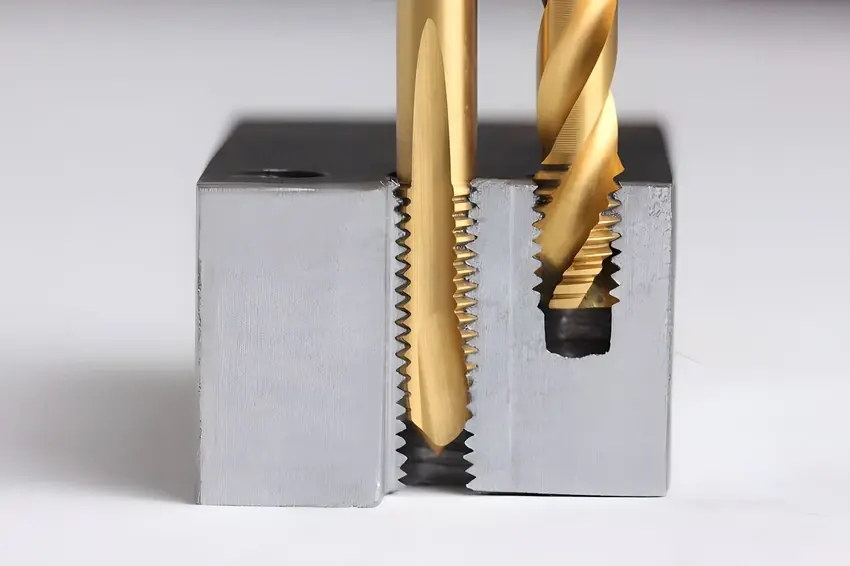

Tapping Blind Holes: Techniques and Challenges

Selecting the Appropriate Tap Type

Choosing the right tap is crucial. Roll taps, which cold form threads, are particularly useful for blind holes as they eliminate the chip problem associated with traditional cutting taps. This method presses the material into the hole walls, creating a stronger thread.

Calculating Proper Drill Depth for Tapping

To calculate the proper drill depth, you must consider the tap’s thread engagement length and the material’s properties. Ensuring the correct tap depth is vital to avoid tap breakage and ensure successful threading.

Common Tapping Issues and Solutions

Common issues include tap breakage, incomplete threads, and damaged thread forms. Solutions involve proper lubrication, chip evacuation, and maintaining the tap’s alignment with the hole’s central axis. Troubleshooting these issues requires understanding the tapping process and its intricacies.

Blind Hole Callouts and Technical Documentation

Blind hole callouts play a vital role in ensuring that machining projects meet their intended specifications. Accurate documentation is crucial for the successful execution of these projects.

Standard Symbols and Notations

Standard symbols and notations are used to convey critical information about blind holes. For instance, the notation “M20 x 2.5” indicates the fastener size and thread pitch. The downward-pointing arrow symbol (↧) denotes the thread tap depth, while the final number specifies the total hole depth.

Specifying Depth and Diameter Requirements

When specifying blind hole requirements, it’s essential to clearly distinguish between thread depth and total hole depth. You should also communicate diameter tolerances and surface finish requirements. Digital design tools can simplify this process by handling blind hole specifications more efficiently than traditional drafting methods.

Other Types of Holes in Engineering and Machining

Beyond blind holes, several other hole types play crucial roles in engineering and machining applications.

Counterbore and Spotface Holes

Counterbore holes are used to enlarge another hole, typically to accommodate a bolt head or nut. Spotface holes, on the other hand, are used to provide a smooth surface for a fastener. Both are crucial for ensuring proper fit and function of parts.

Countersunk and Counterdrill Holes

Countersunk holes are designed to accept countersunk screws, providing a flush surface. Counterdrill holes involve drilling a larger hole followed by a smaller one, often used for screw clearance. These holes are vital for achieving the desired assembly and aesthetic finish.

Tapered Holes

Tapered holes are characterized by their angled sides, making them wider at the entrance than at the bottom. They are used for applications like tool holding and pin fits, offering self-locking or self-releasing functions based on the taper angle. Common taper standards include Morse, Brown & Sharpe, and Jacobs.

Advantages and Disadvantages of Blind Holes

The use of blind holes in engineering and design presents both opportunities and limitations. Blind holes are used in various applications, offering specific benefits while also posing certain challenges.

Strength and Structural Benefits

Blind holes provide structural benefits by allowing for the use of fasteners without compromising the material’s integrity on the opposite side. This is particularly useful in applications where material strength is critical.

Aesthetic and Design Advantages

From a design perspective, blind holes offer aesthetic advantages by concealing fasteners, creating a smoother surface finish. This is beneficial in consumer products and architectural features where appearance matters.

Limitations and Challenges

However, blind holes also have limitations, such as difficulties in chip evacuation during drilling, challenges in tapping, and potential deformation in soft materials. These challenges can affect the quality and functionality of the blind hole.

Conclusion

Blind holes are a fundamental element in engineering and manufacturing processes. They offer structural benefits, aesthetic advantages, and space optimization. Proper design and machining techniques are crucial for successful implementation. Understanding blind holes contributes to better product design and manufacturing.