Beryllium copper (BeCu) stampings deliver high strength, non-sparking safety, and excellent conductivity in one alloy. No other strip material balances spring force and current flow so well for critical components. If you are designing high-performance connectors, switches, or battery contacts, this alloy is essential.

The following sections detail this important alloy’s characteristics and clarify why engineers frequently select BeCu over alternatives. This includes the stamping process, specialized finishes for harsh environments, and current implementations of custom BeCu components in critical applications.

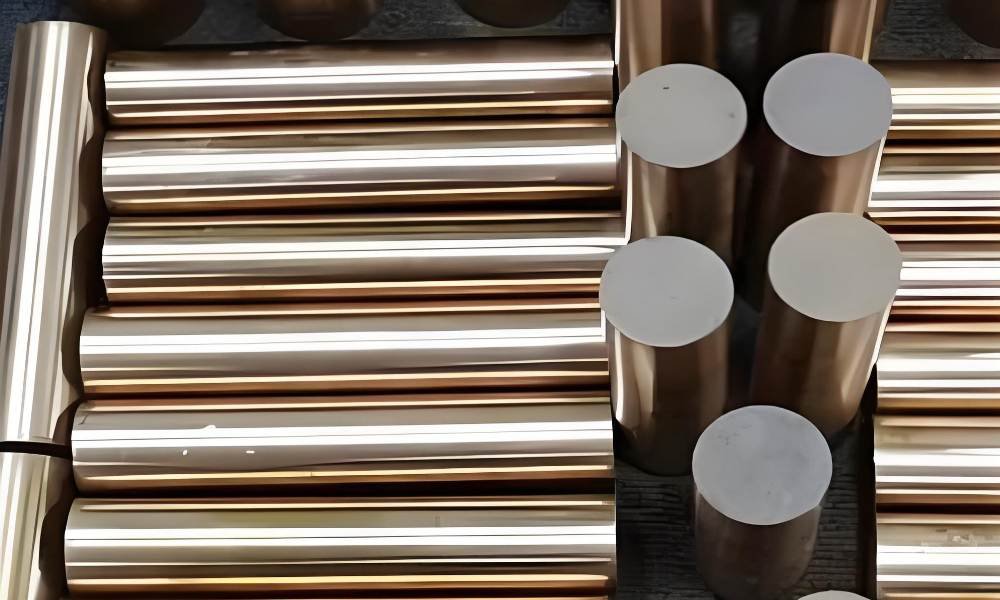

What Is Beryllium Copper?

Understanding BeCu starts with its unique properties. This section defines the material and highlights the features that set it completely apart from standard copper alloys used in the industry.

Basic Definition

Beryllium copper (BeCu) is a special alloy containing 0.5-3% beryllium. It is a precipitation-hardenable material. This alloy combines the superior electrical conductivity of copper with a mechanical strength that can actually rival many common steels. It is truly ideal for demanding copper stamping jobs.

Key Physical Properties

The tensile strength of BeCu varies significantly based on the heat treatment used; however, in relation to all other types of copper-based alloys, BeCu has extremely high electrical conductivity and can transmit electricity with maximum efficiency. Additionally, as a superior thermal conductor, BeCu outperforms other materials such as stainless steel and is also non-magnetic and non-sparking, making it an excellent material for use in hazardous environments.

BeCu stampings also offer excellent fatigue resistance. This means components like springs can endure millions of flexing cycles without failure. This combination of high strength, high conductivity and safety makes BeCu the preferred material of choice for demanding applications.

Comparing Common Copper Alloys

- Beryllium Copper (BeCu): Offers the absolute highest strength and fatigue life. It requires a special heat process (annealing) for good shaping. It has high conductivity but comes at a high material cost. Ideal for battery springs and demanding contacts.

- Brass (Cu-Zn): Known for excellent ductility and is very cheap. It is easily formed but only has moderate conductivity. Best for simple parts like decorative shields and weak spring clips.

- Phosphor Bronze (Cu-Sn-P): Provides excellent resistance to fatigue and corrosion. It has medium conductivity and a moderate cost. A good choice for durable parts like switches and relay springs.

- Copper-Nickel-Silicon (C70250): A Be-free option that delivers high strength and high conductivity. It forms well and is a mid-range cost solution. Used for automotive pins and solder tabs.

- Leaded Brass (C36000): Offers the best machinability after stamping. It is low-cost with moderate conductivity. This material is used when stamped parts need later threading or drilling.

- Pure Copper (ETP): Delivers the highest electrical and thermal conductivity. It is excellent for forming but is very soft. Essential for carrying power, such as bus bars and heat-sink fins.

- Copper-Nickel (Cu-Ni): Provides superior corrosion resistance against seawater. It has low conductivity but forms well. Primarily used for marine-grade components like resistor plates.

Why Choose Beryllium Copper for Metal Stamping?

Selecting the proper material is critical to the performance of beryllium copper stampings. BeCu offers five key benefits that contribute to the rise in overall popularity for applications requiring highly reliable components.

Strength-to-Weight Edge

BeCu delivers high strength with only a moderate density, thus it allows for the possibility of a BeCu stamped part to replace a thicker part made from materials like phosphor bronze. This development creates additional package height savings within limited connector assembly envelopes, producing a more compact and lightweight assembly overall.

Electrical & Thermal Performance

Imagine contacts in an EV battery pack. Beryllium copper stamping customized contacts can carry a substantial amount of current while managing heat better and staying cooler than most alternative materials. This level of performance is impossible to achieve with stainless steel and would require oversized parts if you chose brass.

Spring Quality & Fatigue Life

Miniature EMI fingerstock is a great example. If it is formed by beryllium copper stamping customized, it can survive millions of deflections and cycles with minimal permanent set or deformation. This capability is essential for extending the service intervals of critical components in telecom racks and other high-reliability systems.

Harsh-Environment Survival

BeCu stamped parts are perfect for tough jobs. For instance, non-sparking pump diaphragms can easily pass difficult corrosion tests. They show long-term salt-spray performance without pitting or degradation. This makes BeCu an ideal material for critical components like valve springs used deep in oil-field equipment.

Machinability vs Other High-Strength Alloys

While the final, hardened part machines quickly, manufacturers often stamp BeCu in a softer, annealed (A) condition. This soft material temper makes the metal highly ductile, which is necessary for complex metal stamping operations like deep drawing. The ability to form the part first and then harden it afterward is a major design flexibility that materials like stainless steel simply do not offer to manufacturers.

How Does Beryllium Copper Stamping Work?

Stamping BeCu involves specialized steps, particularly due to the mandatory age-hardening process. Let’s look at the key stages involved in transforming the raw strip into a finished part.

Tool Steel & Die Design

For a high-volume run of beryllium copper stamping, manufacturers must use premium tool steels or hard carbide inserts in the stamping dies. Applying appropriate coatings is also necessary to lower galling and effectively extend the intervals between die sharpening. These steps ensure precision and a longer die life.

Coil Preparation & Lubrication

Manufacturers must apply a suitable vanishing lubricant to the coil strip. This prevents any surface issues, especially during challenging processes like deep drawing. To reduce spring-back after forming, the material’s grain direction should be kept perpendicular to the desired bend axis.

Progressive vs Fourslide Process

There are two main choices for high-volume metal stamping. The Progressive process offers high speed and a very tight pitch, making it perfect for thin battery shims. Alternatively, the Fourslide process can form complex 3D parts, like antenna clips, in a single stroke, which eliminates the need for any downstream bending operations.

Critical Stamping Operations

For blanking and piercing, manufacturers should use carbide inserts. The clearance must be carefully controlled to limit the size of edge burrs. When piercing very small features like oil holes, special punches are needed to vent air. This prevents a phenomenon called slug pulling that can deform small slots in the part.

When forming a bend, a careful wipe-down radius must be used. This prevents micro-cracks from starting in the age-hardened surface of the material. Finally, coining is a local compression process used to set the contact high-points. This ensures they fall within a narrow dimensional band before plating.

| Operation | Purpose | BeCu-Specific Notes |

| Blanking | Cut outer profile | Tighter clearance than brass—reduces burr |

| Piercing | Slots & vent holes | Back-pierce to push burr away from mating surface |

| Forming | 3D features | Must be formed in soft, annealed (O/AT) temper to prevent cracking |

| Coining | Tune spring rate | Local thickness adjustment raises contact force |

Age-Hardening In-House Control

After metal stamping, the parts must be loaded onto suitable carriers for the heat treatment. A controlled atmosphere is used to guarantee the target hardness is reached with minimal dimensional change. This precise control is absolutely critical for producing high-quality beryllium copper stamping customized components.

Quality Checks Unique to BeCu

Manufacturers should implement a few unique quality checks for BeCu. They perform conductivity sampling on every batch to ensure performance. They also run alloy verification tests to catch any composition drift. A final check is a micrograph examination to look for any signs of precipitate over-aging in the material structure.

Ready to launch your BeCu component? The precision required for this alloy demands a skilled partner. Contact Fecision to ensure expert execution from die design to final heat treatment.

Beryllium Copper Stamping Finishes

The environments BeCu stampings operate are often harsh, demanding specific surface treatments. Explore the high-performance finishes available to optimize function and lifespan.

Selective Gold over Nickel

The combination of soft-gold over nickel is an excellent choice for plating. The gold provides a very low contact resistance, and the hard nickel base layer allows the part to survive many insertion and withdrawal cycles. This finish is ideal for board-to-board customized beryllium copper stamping connectors where reliability is paramount.

Matte Tin

Reflowed tin offers a surface that is highly solderable for assembly onto a circuit board. This finish is applied while still maintaining the full spring force of the BeCu part. A special whisker-mitigated bath must be used. This process helps keep the compressive stress in the plating low, which is vital for a long life in high-vibration applications like automotive environments.

Silver Flash

A silver flash is a thin layer of highly conductive silver. Manufacturers plate it onto bus-springs or other parts meant to carry maximum current. The goal here is to push the overall electrical conductivity of the component even higher. This specialized finish is often used in sensitive, high-frequency devices such as advanced 5G antenna modules.

Black Oxide & E-Coat

For military or harsh industrial applications, a finish of military-grade black oxide followed by an epoxy e-coat can be applied. This combination significantly raises the part’s salt-spray performance for extreme environments. It also creates a non-reflective surface, which is necessary for light-sensitive components like opto-mechanical shields in precision equipment.

Passivation Only

Citric acid passivation is a finishing process that chemically strips the surface of any Beryllium Oxide (BeO) contamination. It leaves behind only a thin, clean oxide film. This is the perfect treatment for parts used in medical tools, such as stylets or implants. It ensures the finished part avoids any possible allergic nickel exposure for the patient.

Applications of Beryllium Copper Metal Stamping

The unique properties of BeCu have made it indispensable across high-tech and high-safety sectors. Here are some examples of where you will find these specialized stampings today.

Industries Relying on BeCu Stampings

Many high-reliability industries rely heavily on beryllium copper stampings. In Aerospace, you will find them in flight-control sensors and satellite battery clamps. The Medical sector uses them for catheter guide springs and MRI-safe surgical clips. The Electronics industry is a major user for critical components like CPU socket springs and RF micro-switches.

For the Automotive sector, they are crucial in engine management sensors and EV battery cell contacts and springs. Finally, in Defense & Oil-Gas, their non-sparking property makes them indispensable for non-sparking tools, enclosure components, and connector pins used in hazardous environments.

| Sector | Drivers | Typical Environment |

| Aerospace | MIL specs, out-gassing | Wide temperature, high vibration |

| Automotive | Thermal shock, mixed gas | Under-hood, long life |

| Medical | Biocompatibility, MRI safe | Non-magnetic, sterilizable |

| Electronics | High mating cycles | Low force, data-rate critical |

| Energy | Explosion-proof | Non-sparking, sour-gas exposure |

Typical Parts Stamped from Beryllium Copper

The versatility of the material allows it to be shaped into many critical components through customized beryllium copper stamping.

- Connectors & Contacts: Manufacturers stamp EV bus-bar contacts that reliably carry high continuous current, and high-precision fuse clips designed with controlled contact force for ultimate safety.

- Springs: The excellent fatigue resistance is used for micro-springs for pump valves, often utilizing ultra-thin gauge BeCu. BeCu is also key in creating specialized, high-reliability springs found in sensitive regulators.

- EMI/RFI Shielding: BeCu forms EMI shield fingers used on high-speed 5G modules. This protects sensitive electronics and signals from interference, providing reliable and effective protection against electronic noise.

- Specialized Components: Its unique properties are used in demanding environments for down-hole sensor sleeves that must resist immense pressure and high temperatures. In hazardous settings, the non-sparking property is essential for creating tool sleeves.

Conclusion

Beryllium copper stamping is the only solution that truly merges high electrical conductivity with reliable spring strength. However, achieving this performance is only possible when the manufacturing process controls every factor. This includes every bend, every tiny burr, and every micron of plating thickness. You need a trusted partner who can guarantee this level of precision.

At Fecision, we specialize in complex BeCu stamping. Our ISO 9001 and IATF 16949 certified processes ensure the quality needed for high-current EV contacts and aerospace components. We provide high-accuracy components with tolerances down to ±0.001 inches for your most critical designs.

We offer engineering support from DFM to final delivery. Our deep experience means faster material selection and process optimization for challenging alloys like BeCu. This ensures you get a cost-effective, high-performance spring or connector with a faster lead time.

Ready to start your high-performance BeCu project? Request a quote from Fecision today.