Are you looking for an effective way to clean, polish, or prepare surfaces for further treatment? Bead blasting is a specialized surface finishing technique that uses small beads propelled at high velocity to achieve the desired surface finish. This process is widely used across various industries, including automotive, aerospace, and general manufacturing, as a cost-effective way to achieve consi stent surface finishes on different materials.

By understanding the principles of bead blasting, you can make informed decisions about surface finishing options for your custom parts and projects. This comprehensive guide will walk you through everything you need to know about the process, from basic principles to equipment selection and best practices.

What Is Bead Blasting

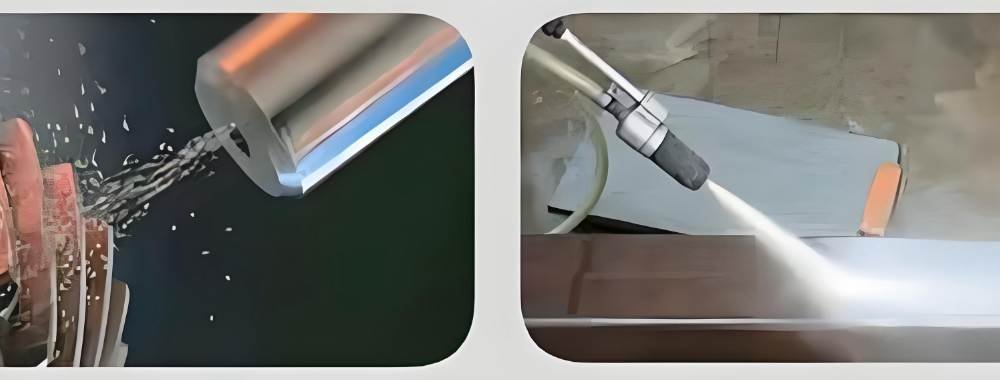

With its roots in traditional sandblasting, bead blasting has evolved to offer a gentler alternative for surface treatment. This method uses fine glass beads propelled at high velocity to clean or smooth surfaces. Bead blasting is particularly effective for removing surface contaminants without damaging the underlying material. The basic principle behind bead blasting is to use the kinetic energy of the beads to gently abrade the surface, resulting in a clean and smooth finish.

The development of bead blasting can be traced back to the need for more precise surface treatment in industries like aerospace and automotive. Key milestones include advancements in manufacturing technology that allowed for the production of uniform glass beads and the development of automated blasting cabinets with precise pressure and media control. Environmental concerns about traditional abrasives also drove the adoption of glass beads, which produce less hazardous dust.

How Does Bead Blasting Work

To understand how bead blasting works, it’s essential to look at the equipment and process involved in this surface treatment method.

The Bead Blasting Process Explained

The bead blasting process involves propelling fine glass beads at a material to achieve a smooth finish. This is done within a containment system known as a blast cabinet, which comes in various sizes to suit different applications. The cabinet is equipped with a viewing window, allowing the operator to monitor the process.

Equipment and Setup Requirements

The equipment required for bead blasting includes abrasive media, a blaster nozzle, gloves, and a blast cabinet. The setup requirements for a bead blasting operation include proper ventilation and dust collection systems to maintain air quality and recover media for reuse. The configuration of the equipment affects the efficiency and quality of the bead blasting process.

Types of Abrasive Media Used in Bead Blasting

The success of a bead blasting operation largely hinges on the selection of the right abrasive media. Different materials and surfaces require specific types of media to achieve the desired outcome without causing damage.

Glass Beads: The Standard Option

Glass beads are a popular choice for bead blasting due to their versatility and effectiveness on a variety of surfaces. They are ideal for cleaning and surface preparation without leaving residue.

Steel Shot: For Heavy-Duty Applications

Steel shot is used for more demanding applications where a higher level of abrasion is required. It’s particularly useful for cleaning heavy machinery and equipment.

Aluminum Oxide: The Etching Alternative

Aluminum oxide is a highly abrasive media used for etching and preparing surfaces for coating. It’s known for its hardness and ability to cut through tough materials.

Plastic Media: The Gentle Approach

Plastic media blasting is a gentle and effective method for cleaning delicate surfaces. Made from recycled plastic materials, it’s highly reusable and ideal for stripping paint and deburring plastic parts without damage.

Advantages of Bead Blasting

With its unique combination of precision and safety, bead blasting stands out as a superior surface treatment method. This process offers several benefits that make it an attractive choice for various industries.

Surface Finish Quality and Consistency

Bead blasting provides a high degree of control over the surface finish, allowing for consistent results. The adjustable parameters, such as pressure and media flow, enable fine-tuning of the blasting action to achieve the desired finish.

Environmental Benefits

Bead blasting is an environmentally friendly process as it doesn’t generate heat or involve harsh chemicals. The use of recyclable media further reduces its environmental footprint.

Precision and Control

Modern bead blasting equipment incorporates precision controls, allowing for repeatable results even with different operators. This precision makes bead blasting suitable for delicate materials and complex workpieces.

Limitations and Disadvantages

While bead blasting is a versatile surface finishing technique, it has its limitations.

Time and Resource Considerations

Bead blasting can be a time-consuming process, especially when working with complex geometries or large surfaces. The need for proper equipment setup, media selection, and safety precautions adds to the overall resource requirements. You must consider these factors when planning your bead blasting operations to ensure efficient use of time and resources.

Material Compatibility Issues

Bead blasting may not be suitable for all materials, particularly very soft metals, thin-walled components, or certain plastics that could deform under blasting pressure. The choice of abrasive media and blasting pressure must be carefully considered to avoid damaging the surface. Some materials may experience work hardening or stress during the blasting process, potentially affecting their mechanical properties. When working with parts that have varying material hardness or complex geometries, achieving a uniform finish can be challenging.

Bead Blasting vs. Sand Blasting: Key Differences

When it comes to surface preparation, two popular methods often come into discussion: bead blasting and sand blasting. The primary differences between these techniques lie in the abrasive media used, the surface finish they produce, and their suitability for various applications.

Abrasive Media Comparison

Bead blasting typically employs glass beads, which are less abrasive than the sand particles used in sand blasting. This makes bead blasting ideal for delicate surfaces, such as car body panels and engine parts, where a gentler approach is necessary.

Surface Finish Results

The surface finish produced by bead blasting is generally smoother and more polished compared to sand blasting. Sand blasting, on the other hand, can create a rougher surface, which is often desirable for applications requiring maximum adhesion.

Application Suitability

Bead blasting is preferred for finishing delicate components, preparing surfaces for high-quality coatings, or cleaning without dimensional changes. In contrast, sand blasting is more suitable for heavy rust removal, thick coating stripping, or creating a rough surface for maximum adhesion. The choice between the two methods also depends on the material being treated, with softer or thinner materials generally better suited to bead blasting.

Common Applications of Bead Blasting

Bead blasting is a widely adopted technique in various industries, offering a gentle yet effective way to clean and prepare surfaces. This process has a wide range of applications, making it a valuable tool for numerous sectors.

Automotive Industry Uses

In the automotive industry, bead blasting is used for cleaning engine parts, removing rust, and preparing surfaces for painting or coating. It’s an essential step in restoring classic cars and maintaining modern vehicles.

Aerospace Applications

The aerospace industry relies on bead blasting for cleaning aircraft components, removing contaminants, and preparing surfaces for inspection or further processing. Its precision is crucial for maintaining the integrity of aircraft parts.

Medical Device Manufacturing

Bead blasting is used in medical device manufacturing to clean and finish medical implants, surgical instruments, and other equipment. It ensures the removal of contaminants and improves surface finish, enhancing the safety and efficacy of medical devices.

General Manufacturing and Restoration

General manufacturing industries use bead blasting for deburring machined parts, removing tooling marks, and preparing surfaces for painting or coating. Restoration work, such as cleaning antiques and historical artifacts, also benefits from the gentle cleaning action of bead blasting.

Best Practices for Optimal Bead Blasting Results

Bead blasting can be highly effective when done correctly, with attention to detail being paramount. To achieve the desired finish, several best practices should be followed.

Pressure and Distance Control

Controlling the pressure and distance of the blasting nozzle from the surface is critical. Adjusting the pressure according to the material being blasted ensures that the surface is not damaged. Keeping the nozzle at an optimal distance helps in achieving a uniform finish.

Media Maintenance and Replacement

Regular maintenance of the bead blasting media is essential to prevent contamination. Replacing the media as needed ensures consistent results. This practice is particularly important when working with surfaces that have heavy rust or paint, as contaminants can interfere with the blasting process.

Surface Preparation Tips

Before bead blasting, the surface should be cleaned to remove oils, greases, and loose contaminants. Pre-treating heavily rusted or painted surfaces with chemical cleaners can improve blasting efficiency. Proper masking techniques should be used to protect threads and precision surfaces.

Conclusion

The bead blasting process is widely used across various industries for its versatility in surface finishing. It offers a wide range of applications, from cleaning and deburring to texturizing surfaces.

Bead blasting provides consistent finishes on various materials while maintaining dimensional accuracy. Whether you’re manufacturing new parts or restoring old ones, considering bead blasting for your surface finishing needs can be beneficial. Proper understanding of bead blasting fundamentals leads to better decision-making for your surface finishes.