Manufacturing engineers often find it hard to pick materials that are both strong and affordable. Metals like steel and aluminum sometimes don’t meet the need for something that is super durable but also lightweight. This is especially important in fields like aerospace and medical devices where parts must not fail.

Titanium in such situations has become a top choice. This is because it is very strong but light, resists rust and corrosion. It works well with the human body. These special qualities make titanium perfect for use in medical, aerospace, and car industries. There are multiple challenges as well which make titanium hard to machine.

However, here we will explore how titanium CNC machining work and why it is becoming a popular choice for manufacturers.

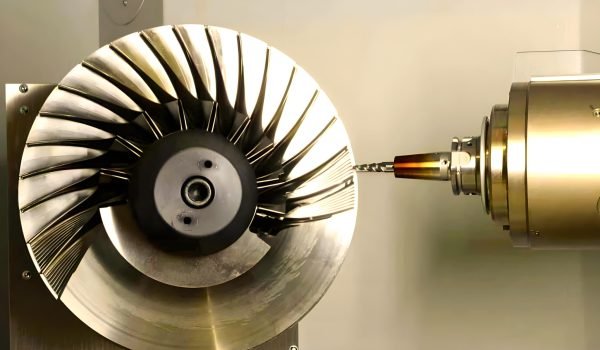

How Does Titanium CNC Machining Work?

CNC Machining titanium means paying close attention to:

- Controlling heat

- Picking the right tools

- Using proper cooling

- Keeping the machine steady.

It is important to carefully set the cutting speed, feed rate, and tool movements. This is because titanium does not spread heat well and reacts easily. Using slower cutting speeds with faster feed rates helps control heat where the tool cuts. This protects both the tool and the metal.

Carbide tools with special coatings like Titanium Aluminum Nitride or Titanium Carbonitride are the best choice. This is because they handle high heat and last longer. Using techniques like smooth tool entries, climbing cuts, and small cutting widths helps avoid tool damage and chipping. Also, using a strong, stable machine, holding the workpiece firmly, and keeping the tool close to the machine reduce vibrations and improve accuracy.

Why Titanium is Used in CNC Machining?

Titanium machining is special because of a few key qualities that really stand out.

- Strength and Lightweight

Titanium is very strong but weighs about half as much as some steels. This makes it perfect for industries where keeping weight low is important.

- Corrosion Resistance

Titanium does not rust easily even in seawater. That is why submarines and marine gear often use it. It holds up great in tough and salty environments.

- Biocompatibility

Titanium works well with the human body. This is why it is often used for medical implants and prosthetics.

- Cost Considerations

Titanium can be expensive. However, it can save money over time because it lasts a long time and is very durable.

- Resilience in Heat

Titanium can take really high temperatures. This is making it ideal for parts in jet engines and rockets.

Different Techniques Used for Titanium CNC Machining

Here are the Key Techniques used for titanium CNC machining:

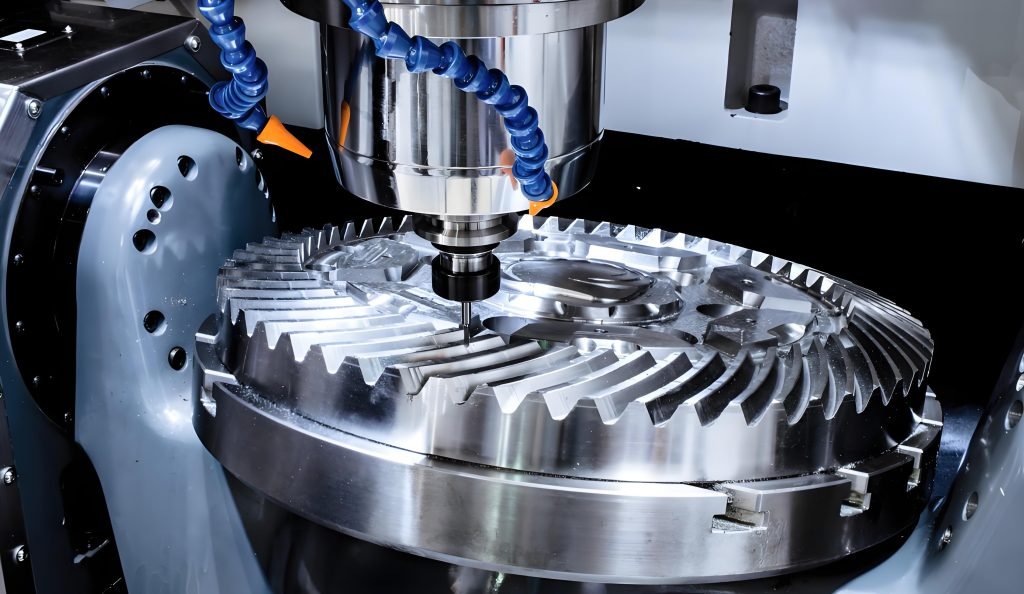

Conventional Machining Techniques

Traditional machining methods like turning, milling, drilling, and sawing are still the main ways to work for making custom titanium parts. However, these methods need some special adjustments. This is mainly because titanium can get hot and harden during cutting.

Turning

You need a strong setup and the right tools when turning titanium. This is because titanium is stretchy and can harden while being cut. Use low speeds but high torque to handle the pressure during cutting and to avoid tool shaking or bending.

Keep the cutting speed steady to stop the metal from hardening too much. Change the cutting depth a little with each pass to wear the tool evenly. Also, use high-pressure coolant to cool the tool and wash away chips. This helps tools work better and makes better parts.

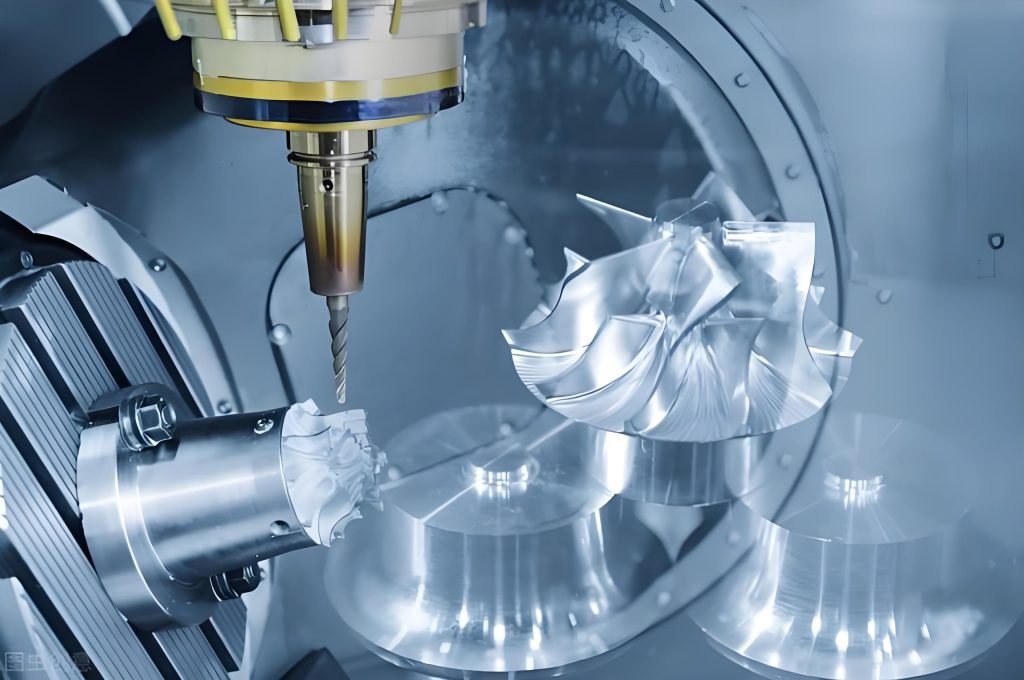

Milling

Milling titanium means using machines with strong and steady spindles because the metal is tough. You want to use low speeds but high torque to keep the tools safe. Climb milling is best because it helps create chips that cool down the cutting edge better.

Here is how to get good results:

- Keep the cutting width low to lighten the tool’s load.

- Use tools with many cutting edges to spread out the heat.

- Use smooth, curved tool paths and add small chamfers at tool exits to protect the tool and the part.

- Use a low feed rate per tooth and keep your cutting settings steady to make your tools last longer.

Drilling

Drilling titanium needs a strong setup and special drill bits coated with materials like TiAlN to handle heat and stop the bit from sticking. Here is how to do it right:

- Use high-pressure coolant to cool the drill and wash away chips.

- Keep a steady feed speed to avoid rubbing. This can wear out the drill quickly.

- Use peck drilling to keep the hole clean and stop the drill from overheating.

Sawing

It is best to use abrasive blades or saws with carbide tips when sawing titanium. This is because titanium is very hard.

Here is what to keep in mind:

- Keep the blade tight and use the right speed for clean cuts.

- Use plenty of coolant or oil to stop the blade from getting too hot and reduce friction.

- Feed the saw at a moderate speed to keep heat down and make the blade last longer.

Titanium Alloy Types for CNC Machining

Titanium is famous for multiple reasons. However, machining titanium alloys can be tricky because of their special properties. Here is a quick look at some common types:

- Grades 1-4

These are pure titanium with no added metals. Grade 1 is the softest and easiest to machine. The metal gets stronger but harder to shape as you move up to Grade 4.

- Grade 5

It is very strong, tough, and heat-resistant. It is harder to machine than pure titanium but it is common to use in planes and medical implants.

- Ti-5-5-5-3

This alloy is very strong and tough but also harder to machine. This is because it is quite hard.

- Ti-407

This one is softer and easier to shape than Grade 5. This is making it a good choice when easy machining is more important than maximum strength.

Applications of Titanium CNC Machining

Titanium is popular because it combines toughness with lightness. Therefore, it is common to use in many industries including:

- Aerospace

- Medical

- Automotive industry

- Marine

- Defence and military

What Are Common Titanium CNC Machining Challenges?

Every metal has its own challenges and titanium is no different. Machining titanium with CNC machines takes special skills, the right techniques, and patience. Here are some common challenges of Titanium CNC Machining to know;

- Controlling Heat

Titanium does not spread heat like aluminum does. This can cause heat to build up in one spot which wears tools out faster.

- Dealing with Tool Wear

Titanium is very strong which is great for the final product. However, machining titanium also makes tools to wear out quickly. Different types of titanium wear tools at different rates. So, picking the right material and using tough carbide tools or special coatings helps tools last longer.

- Handling Flexibility

Even though titanium is strong, it can bend a little during machining which causes vibrations. Therefore, it is important to use strong machines and secure the parts firmly to keep everything steady.

Get Expert Titanium CNC Machining Services from Fecision!

Making titanium parts takes experience and the right tools. Fecision provides titanium CNC machining services for everything from prototypes to full production run. We are working with many types of titanium alloys. Our skilled engineers use modern CNC machines to help businesses make strong and reliable parts for multiple industries. So, you can rely on us for expert China titanium CNC machining services anytime.