Move beyond the limitations of 3D-printing materials—an injection mold prototype delivers production-grade resin in days, letting you drop-test, sell-test and scale-test before you sink capital into hardened steel. This early testing strategy saves time and huge amounts of money in the long run.

In the next minutes you’ll learn what prototype molds really cost, when aluminium beats steel, how rapid prototype molding slashes market risk, and a partner checklist to turn a validated prototype injection mold into a million-shot production tool.

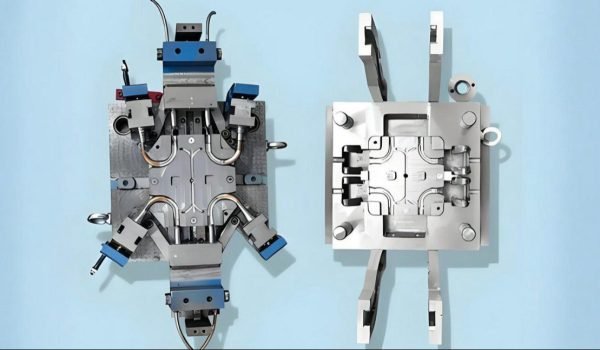

What Are Prototype Molds?

A prototype mold is temporary tooling that uses real plastic resin for small production batches. These batches can be anywhere from tens to thousands of parts. This step is key for checking your design, getting early approval from regulators, and getting your product into the market for early reviews. It is a very important step before you start making huge amounts of product.

Prototype molds are usually made from softer metals, most often aluminium or mild steel. Choosing this material lets manufacturers make the tool much faster and greatly cuts the initial cost compared to making a full-scale production tool. The main goals are speed and keeping costs low while still achieving a great quality part.

Most importantly, the parts you make from a prototype mold give you the exact same mechanical, heat, and look data as parts made in mass production. This is absolutely vital for making sure the part fits right, works correctly, and for showing off your product to investors. It guarantees your product will work exactly as you planned.

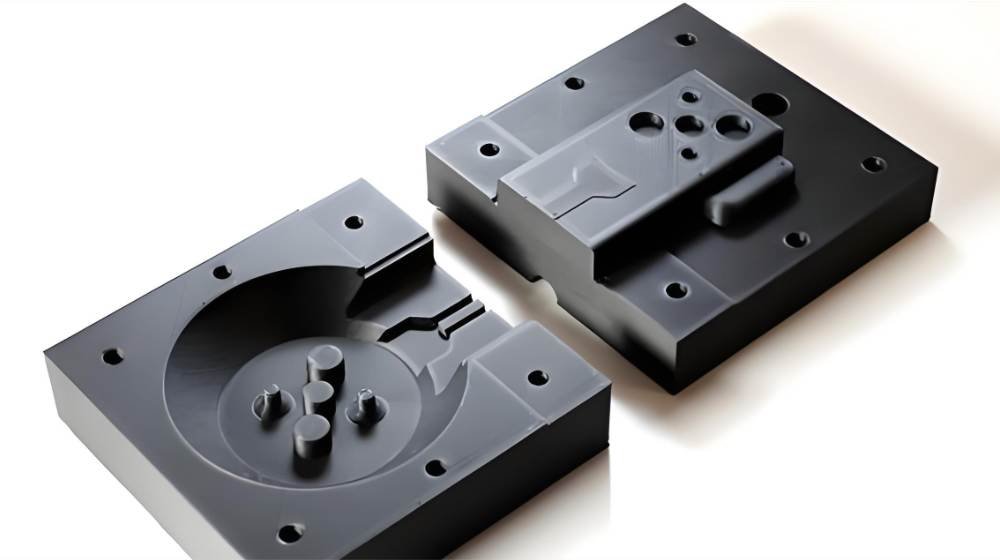

Aluminium vs. Steel for Prototype Molds

Choosing the right metal for your mold is key. It controls speed, part volume, and part finish. The wrong choice costs you time and money.

Thermal Conductivity Gap

Aluminium alloy 6061 conducts heat several times faster than P20 tool steel. This massive difference in heat transfer capacity significantly cuts the overall cycle time in prototype mold making. Faster cooling also helps in reducing sink marks, especially in parts that have thick ribs or bosses. This leads to better part quality much faster.

Durability & Shot Count

Aluminium prototype injection molds are comfortably able to deliver hundreds up to a few thousand shots. For projects needing higher volumes, steel tooling is necessary, as it can jump to high-thousands or more parts. However, opting for steel tooling adds several extra weeks to the manufacturing and machining lead time.

Machinability & Design Changes

Soft aluminium is much easier and quicker to machine, meaning it can accept design tweaks and modifications almost overnight. In contrast, reworking and adjusting steel tooling burns significant budget and requires many more spindle hours on the CNC machine. Aluminium allows you to iterate quickly and cheaply.

Surface Finish Reality

When they are brand new, both aluminium and steel can achieve a very high gloss surface finish. The reality is that aluminium tooling degrades faster over time and with repeated shots. The good news is that a professional diamond polish can easily restore the gloss for hundreds of additional prototype shots, extending the tool’s life.

Cost per Cavity

The cost is largely dominated by the CNC machining time required. An aluminium core and cavity pair costs noticeably less due to the easier machining. Using an identical P20 steel set raises the price significantly. You must factor this critical cost difference when selecting your prototype & plastic mold company.

| Feature | Aluminium (e.g., 6061) | Steel (e.g., P20) |

| Lead Time | Faster (Days to 2 Weeks) | Slower (Weeks) |

| Max Shot Count | Hundreds to Low Thousands | High Thousands and up |

| Cost | Lower | Higher |

| Machinability | Excellent (Easy Tweaks) | Difficult (Expensive Tweaks) |

| Thermal Mgmt. | High Conductivity | Low Conductivity |

Need help choosing? Let Fecision experts guide you on the best material—Aluminium or Steel—for your specific part volume and budget. Get a fast, no-obligation material consultation today.

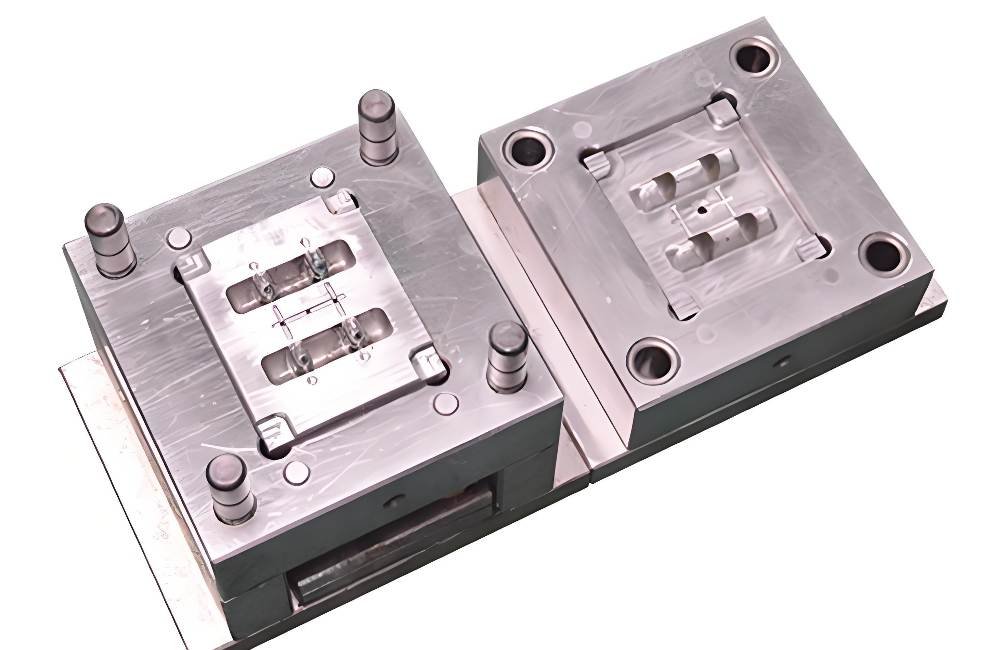

The Prototype Mold Making Process: From Design to First Shots

The workflow is designed to compress a traditional tool build into just a couple of weeks, without sacrificing the crucial accuracy of the injection mold prototyping. This fast process gets your part in your hand quicker for key testing and verification.

Step 1: Requirements Lock & Material Choice

The process begins by finalizing part geometry, resin selection, and critical dimensions. Following this, you must pick your tool material: aluminium for the fastest speed or steel if you absolutely need a higher shot count and more part volume. Making this decision early is very important.

Step 2: Moldflow & Cooling Strategy

Engineers then use advanced simulation tools like Moldflow to predict the fill, pack, and potential warp of the part. Then, a straightforward but effective network of drilled cooling channels is laid out in the mold design. This ensures the parts cool evenly enough for accurate testing, while keeping the mold fabrication fast and affordable.

Step 3: CNC Machining & Polishing

The mold block is hard-milled to a very tight dimensional tolerance band. Micro-EDM technology is used for creating small, complex ribs or sharp features. Finally, the mold is polished in-house to achieve the precise target SPI finish you require. All these steps are performed under one roof for quality control.

Step 4: Assembly & Dry Cycling

Once the components are machined, the mold is carefully assembled. A ‘dry cycle’ test will be performed to verify critical functions like ejector travel, the interlock seal, and the clamp pressure before any hot resin is ever allowed to enter the cavity. This checks for mechanical perfection beforehand.

Step 5: Injection Parameter Matrix

To establish a process quickly, the operator will adjust barrel temperature, injection speed, and pack pressure to find the core settings that yield a sound part for testing. This process focuses on getting an acceptable part quickly, not complex mass-production optimization.

Step 6: First-Shot QA & Refinement

The very first shots are subjected to stringent quality assurance. This involves CMM scanning, tensile tests, and functional tests to confirm the injection mold prototype meets your exact specifications. If necessary, steel-safe features can be adjusted and refined almost overnight to achieve perfection.

Step 7: Sign-Off & Production Bridge

Upon final approval, all critical data will be exported and documented, including cooling coordinates, the proven injection parameters, and full inspection data. This crucial step means that the full production tool can start with minimum learning loss, ensuring a smooth and rapid transition to full-scale manufacturing.

Key Benefits of Using Prototype Injection Molds Before Full-Scale Production

A fully validated prototype injection mold acts as an inexpensive but critical insurance policy against facing late-stage, extremely costly disasters. This early investment minimizes the risk of finding major, expensive design flaws much later in your development cycle.

Risk Reduction

Using a prototype mold allows you to expose and identify weak features or potential failure points in the design early on. At this stage, fixing these issues costs only a few hundred dollars, as opposed to hundreds of thousands of dollars if a flaw is found after the hardened steel production tool has been fully cut.

Design Validation with Real Resin

Using real, finished-product plastic is a must. Plastics like those with glass filling or medical-grade resins act very differently inside the mold than simple 3D printing materials. Only by making a prototype mold will you truly see the actual shrink, warping, and inner stress that your final part will have.

Market Testing & Early Revenue

You can use the parts from the prototype mold to ship pilot units to your early adopters and key customers. This lets you collect valuable, real-world user feedback and refine the User Experience (UX) while the expensive, high-cavitation steel tool is still being machined on the CNC table.

Cost Savings Across the PLC

Industry data consistently demonstrates that the spending dedicated to injection mold prototyping tooling saves you multiples of that cost down the line. These savings come from eliminating expensive engineering-change orders and the need for costly production-tool re-cuts after launch.

Regulatory Dry-Run

Many certification and compliance tests, which are essential for market entry, can be successfully completed using prototype parts. This is a huge advantage as it effectively removes the final approval and testing from the critical path of the final product launch timeline.

Faster Funding & Stakeholder Buy-in

Nothing sells your idea better to potential investors or key team members than a real, high-quality plastic part they can hold and check out. Prototype molds quickly turn computer drawings and presentation slides into solid proof that your product is ready to go.

Applications of Prototype Molds

Almost any industry or sector that needs to get real plastic parts in their hands quickly and for a low volume relies heavily on prototype injection molds. The speed and material fidelity are simply unmatched by other processes.

Medical Devices & Surgical Instruments

Complex micro-fluidic manifolds and surgical instrument handles are validated early in autoclavable resins. Aluminium prototype mold is used for these critical parts before they are transitioned to high-volume, multi-cavity steel tools for final production and deployment.

Consumer Electronics Housings

All types of consumer electronics, from remotes to smart home devices, require tough housing. Over-molded grips and thin walls are rigorously drop-tested using parts from prototype injection molds to ensure they meet tough UL or CE safety standards prior to their public launch.

Automotive Connectors & Sensors

Under-hood nylon parts, such as critical connectors and sensors, must survive grueling heat-age testing. Prototype injection mold tooling is used to confirm seal integrity and mechanical performance before the final PPAP (Production Part Approval Process) can even be initiated.

Aerospace Ducts & Clips

Parts that need to stop fire are often made first using fast prototype molding. These parts can then go straight into required FAA certification flights for checking flammability. This makes the final approval time for aerospace components much, much faster.

IoT & Wearables

Miniature shells for IoT devices and wearables that feature complex mechanisms, such as living hinges, are quickly produced. They pop out of prototype injection molds in short, fast sprints, enabling engineering teams to perform nightly firmware-hardware fit checks and design iterations.

Choosing the Right Prototype & Plastic Mold Company: A Partner Checklist

Selecting the right company is key for your product’s success. You need a partner who can quickly make rapid prototype molds and also handle the big, complex production tools later on. Use this checklist to screen potential partners:

Factory Capabilities (Can They Make It?)

- In-House Experts: Check if they do their design analysis (like Moldflow simulations) right there in their own office. If they send this key work to another company, your project will slow down a lot.

- Handle Both Metals: The best factories can machine both aluminium (for fast prototypes) and steel (for high-volume parts). If they can do both, it makes the switch from testing to mass production easy and smooth.

- Speed Record: Ask for proof of their past work schedules. If it takes them much longer than two weeks to build a prototype mold, you should look for someone faster.

Materials & Quality (Will It Be Right?)

- Big Resin Stock: A great partner keeps tons of different plastic materials on hand—from cheap basic plastics to super strong, special plastics like PEEK. If they have the material ready, you won’t waste time waiting.

- Official Quality Proof (ISO Certs): If your parts are for medical devices or cars, quality rules are strict. Suppliers should hold current ISO 9001 and, especially for medical, the ISO 13485 certificates. These are non-negotiable proof of quality.

Reports & Honesty (Will They Be Clear?)

- Clear DFM Reports: After you ask for a price quote, they should send you a detailed “Design for Manufacturing” (DFM) report very quickly. This report must clearly show where the plastic goes in (gate location) and how much the part will shrink.

Your Next Step: From Prototype Validation to Production Tooling

Choosing a prototype mold is smart because you get real parts fast. Knowing when to use cheaper aluminium instead of steel and following a good plan, means your design is proven. This saves you a lot of money and time before you build the big, expensive production molds.

To go smoothly from your tested prototype to making huge amounts of product, you need one prototype and plastic mold partner who knows the whole tooling process inside and out. Fecision offers you rapid prototype tooling using aluminum or soft tools,to help you find design problems early, fix them easily, and confirm your product idea works. You save money and time before you have to pay for the big, expensive production molds.

Our mold tooling service handles everything: design, testing, and mass production. This makes the move from your fast prototype to the final, hard steel mold very smooth. We cut your launch time and promise you top quality following strict ISO rules.

Ready to launch faster with guaranteed quality? Contact Fecision now to get your first shot parts in hand within days.