In contemporary manufacturing, CNC machining with copper is essential. Traditional methods cannot match the accuracy and efficiency required for copper parts. Copper is essential to various sectors, including electronics, automotive, and medicine. They pick it because of its strength, durability, and conductivity in every application; accuracy is essential.

CNC machining copper solves common challenges. It easily produces complex shapes, improves consistency, and reduces waste. Even on challenging projects, you deliver reliable results. That is why copper CNC machining services matter today.

What Is Copper CNC Machining

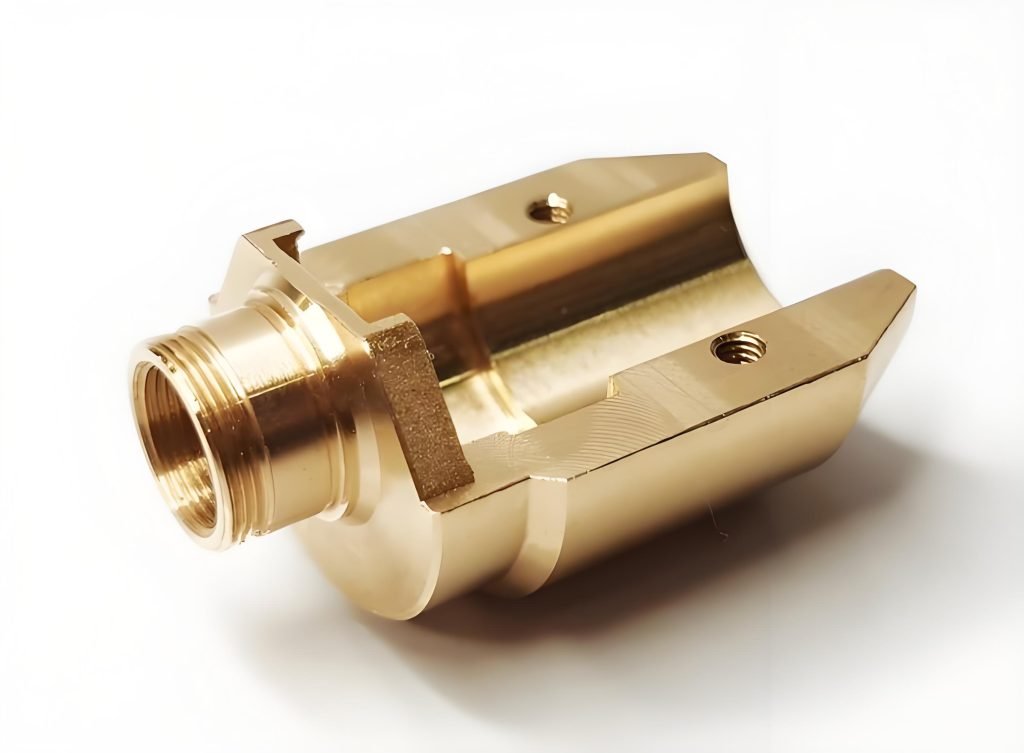

Before you explore the benefits, it is important to understand what copper CNC machining really means. It precisely cuts and shapes copper using computer-controlled machinery. The machine follows precise tool paths when you program parts. Human error and manual guesswork are avoided. You consistently attain tight tolerances; each batch is identical.

How It Differs From Other Metals

Compared to steel or aluminum, copper is softer and more ductile. It influences the selection of copper machining tools and cutting techniques. To avoid deformation, feeds and speeds need to be carefully managed. To preserve accuracy and surface finish, skilled operators adjust parameters for important components.

Why CNC Matters

CNC matters because it ensures repeatable precision across runs. For every feature, you program the tool paths, speeds, and depth. Precise control lowers production costs and minimizes scrap. When parts are designed consistently, quality control is made easier. You obtain reliable results from copper machining.

Why Choose CNC Copper Machining

With its benefits clear, it becomes easier to see why choosing CNC copper machining is the best approach.

· Precision And Repeatability:

Because CNC machining ensures precise part replication, you choose it. Every component can meet the same standards thanks to digital design files.

· Efficiency And Cost Savings:

By carefully removing material, CNC machining copper reduces waste. By reducing scrap and increasing machining efficiency, you can save money.

· Handling Complex Geometries:

With CNC, you can create thin walls and complex channels. You can consistently meet strict tolerances on every run with accurate tool paths. Standard production items now feature complex designs that were previously impossible to achieve by hand. Selecting high-quality copper machining services increases your design flexibility.

Challenges Of Machining Copper

Even with clear benefits, copper machining still presents challenges that must be managed carefully.

· Tool Wear And Burr Formation

The softness of copper leads to burr formation and increased tool wear. Inappropriate tooling may result in rough surfaces and reduced dimensions. For a longer tool life, you need sharp tools and the right coatings. To prevent problems, it is essential to monitor wear and replace cutters on schedule.

· Chip Control Problems

Chip control becomes critical when machining copper parts at speed. Ineffective evacuation causes recutting and rapidly deteriorates the work surface. To keep chips clear, you select chip breakers and feeds that are optimized for the task. Stable cutting operations are maintained by proper coolant flow and tool geometry.

· Heat And Cutting Conditions

Copper conducts heat fast, so you must manage temperatures closely. Overheating reduces cutter life and can cause small parts to warp during the cutting process. To effectively dissipate heat, use controlled speeds and appropriate lubrication. Accurate parts are ensured by skilled operators and well-tuned CNC programs that prevent deformation.

Applications Of Copper CNC Machining

Understanding challenges is only one side. It is equally important to see where CNC copper machining creates value.

· Electronics Industry

It is used extensively in the electronics manufacturing industry. Precise copper features are required for conductive contacts, terminals, and connectors. Precise dimensions ensure long-term reliability and consistent electrical performance. When copper components consistently meet strict specifications, your products exhibit improved performance and maintain consistent, stable conductivity.

· Automotive Industry

Copper is used in automotive systems for both thermal and electrical components. Accurate machining services are required for motor connectors and heat exchangers. Precision components enhance productivity and minimize the risk of accidents on public roads. Repeatable quality is advantageous for automotive applications that are crucial to safety in every model.

· Medical And Industrial Use

Copper is essential for conductance in industrial machinery and medical devices. Precise machining and finishing are essential for components such as heat spreaders and sensors. To ensure the safety and consistent operation of your device, you need trustworthy copper components. High-quality CNC copper machining services meet strict performance and regulatory requirements.

Copper CNC Machining Services You Can Expect

Now that you know the applications, it is useful to look at the core services offered.

· Core Machining Capabilities

You can expect core services like milling, turning, and drilling. Mass production allows designs to be validated through prototyping and short runs. Sophisticated CAM and toolpath strategies optimize every CNC machining job. Your parts benefit from planned sequences and the right cutter choices.

· Precision And Quality

CNC machining copper delivers tight tolerances and smooth surface finishes. Visual checks and CMM are examples of inspection protocols that verify each dimension. To ensure that parts meet functional and reliability requirements, you monitor quality metrics. Your approval criteria guide final acceptance before shipping to assembly lines.

· Customization For Clients

Projects often require specialized setups for copper alloys or shapes that differ from the norm. You can request specific surface finishes, coatings, or inspection plans. Suppliers modify fixtures and sequences to accommodate your design and volume requirements. That level of customization ensures that the final parts fit your needs.

How To Choose The Right Copper Machining Services

After learning what services are available, the next step is selecting the right supplier.

Evaluating Expertise

Seek out a track record of successful CNC copper part machining. Teams that are knowledgeable about feeds, speeds, tool materials, and coatings are what you want. Request case studies and examples that are pertinent to your designs and industry. Experience reduces trial runs and shortens the time to production readiness.

Checking Equipment And Quality Systems

Check for modern CNC machines, rigid setups, and capable. Stable fixtures and sophisticated tooling enhance accuracy in the production of copper components. CMMs and other calibration and inspection tools ensure dimensions stay constant. These systems reduce variation between production batches, support reliable runs, and ensure traceability.

Communication And Support

Select suppliers who maintain open lines of communication throughout the project. You require proactive schedule, cost, and technical change updates. Good partners provide engineering input and offer prompt responses to design queries. Fecision provides reliable machining services, offers quick turnaround times, and offers technical assistance to clients worldwide.

Conclusion:

You now see the importance of copper CNC machining. Due to its characteristics, copper is valuable but challenging to machine. With CNC, you overcome these challenges through precision, repeatability, and efficiency. You acquire reliable components for demanding applications in the automotive, medical, and electronics sectors. Professional copper machining services ensure that mistakes and delays are avoided. Fecision offers reliable CNC machining services utilizing state-of-the-art machinery and skilled personnel. For precision, speed, and personalization, you can rely on our services. Utilizing expert assistance to obtain high-quality copper parts consistently.