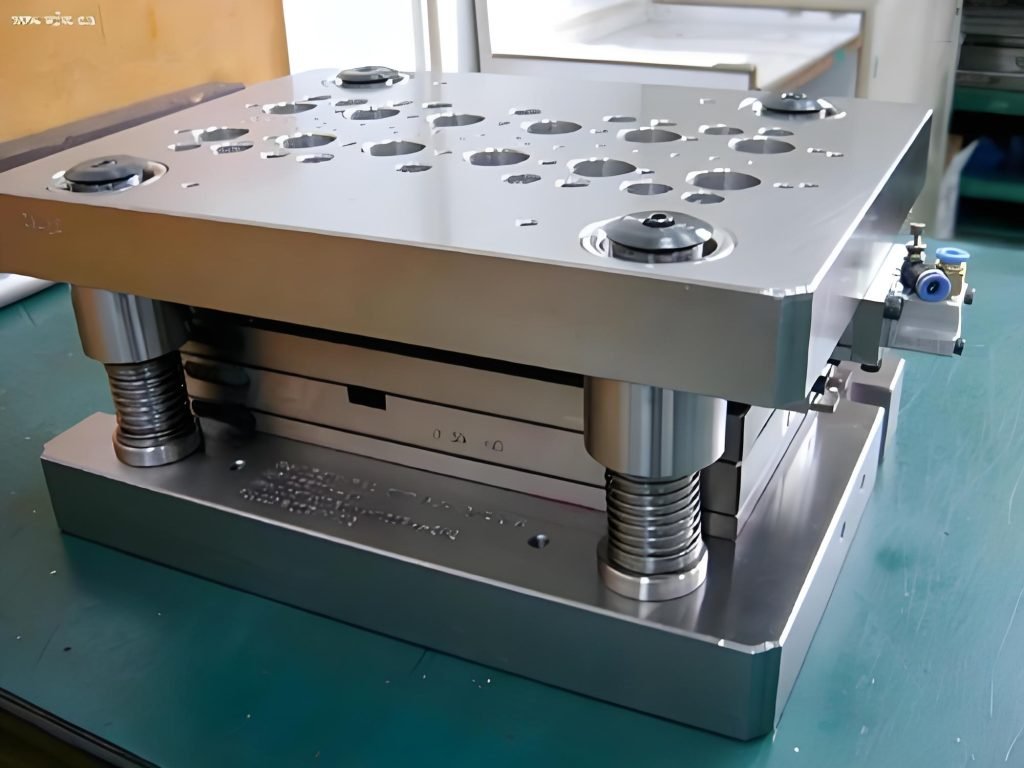

Metal stamping is a powerful way to create very precise metal parts. It’s a process where a stamping die is used to cut or shape sheets of metal. You can think of a stamping die as a large, accurate cookie cutter for metal. It is very common in all kinds of industries to create components, such as automotive engines, airplane components, or electronic devices, and it is chosen for its speed, accuracy, and low cost.

But what about the cost of the stamping dies? It can be very variable, sometimes ranging from a few thousand dollars to hundreds of thousands. There is a very wide range of costs based on many varied factors. Let’s take a deeper look at all of these factors.

6 Key Factors Influencing Metal Stamping Die Costs

How much does a stamping die cost? The price can greatly vary depending on a number of factors. When you understand these considerations, you will have more insight into your stamping die price.

Part Complexity

The more complicated your part, the more complex and costly the die will be. For example, you may have to manufacture a simple part that is a flat shape cut from your sheet (known as “blanking”), for which you would likely use a single-station die with a lower stamping die cost.

But if your part requires deep bends, very tight curves, or has a lot of different features, you will need a “progressive die”. A progressive die does a lot of operations at once while the metal is progressing through it – usually 10 stations or more. Each extra station generally adds about 8–12% to the total cost estimate for your stamping die price.

Material Type & Thickness

The metal itself will also have an impact on the die price. For instance, low-carbon steel is normally the least expensive and easiest to shape. Stainless steel is very strong and has good rust resistance, but it’s also harder on the tools, causing the die to have more maintenance and sharpening, and therefore an overall increased sheet metal stamping die maintenance cost.

Aluminum is very light and soft, but it can sometimes gall the die, which will need special coatings on your custom metal stamping dies. It is also important to note that thicker sheet metal will require more pounds of pressure from the press, which means the die itself will have to be made stronger, and it will, in turn, raise your price.

Initial Tooling Costs

When you need a custom metal stamping die, designed exclusively for your unique part, you will be paying higher up-front costs, because they will require very precise machining or engineering to be completed exactly as planned. It’s like commissioning a custom piece of art – it takes a lot of skilled work.

On the other hand, if you can use a standard die, perhaps for a common part that many people make, it will be cheaper. These standard dies are of standard design, making them capable of being produced faster and more easily. The trade-off is that these standard dies are less flexible and will not meet every unique design you have.

Production Volume

The number of parts you plan to make significantly impacts your overall stamping die cost estimate. If you’re only planning a small production run, the cost of the die itself gets spread out over very few units. This means that the “per-part” cost of the die will be higher for you.

However, if you’re gearing up for mass production, where you’ll be making a huge quantity of parts, the situation changes. The total stamping die costs are being amortized over a much greater number of parts. This allows your stamping die cost estimate to be much lower on a per part basis, ultimately saving you more in the long run when working on high-volume projects.

Finishing Requirements

The kind of finish you want on your final part can also impact the die cost. If a raw finish is acceptable, meaning no special surface treatment is needed, then no extra work on the die is required.

But if you need a mirror polish or a specific textured surface on your parts, it means extra grinding, plating, or coating steps on the die itself. These additional processes contribute to the overall stamping die price. Sometimes, very strict cosmetic requirements might even mean your die needs special features like in-die brushing or vacuum lifters, to ensure perfect parts.

Customization: OEM vs. Standard Designs

When it comes to the die itself, you have choices regarding customization. Using standard die components, such as off-the-shelf punches and guide pins, can help reduce your cost by up to 15–25%. These are available and don’t require being custom-made.

Fully custom metal stamping dies that require some machining for a custom OEM (Original Equipment Manufacturer) logo or even a unique part layout will always have a higher stamping die cost estimate, because custom machining requires the manufacturer to design and make, probably from scratch, to fit your particular needs.

Hidden Costs to Consider

Besides the stamping die price, you should be aware of other costs when budgeting. Forgetting to plan for these costs can build up to hidden costs.

Maintenance & Resharpening

Just like any tool, sheet metal stamping dies need regular care. After a certain number of uses, usually from 50,000 to 200,000 “strokes” or parts produced, the cutting edges of the die will become dull; the die will need to be re-ground.

Plan for ongoing maintenance and upkeep at about 5–10% of the original cost of the stamping die each year, to ensure the die performs at its best and can keep producing parts at a high-quality level without increasing your operational cost.

Design & Engineering Fees (if Outsourced)

If you are not doing the part or die design in‐house, you will also incur those design and engineering costs. When creating CAD (Computer-Aided Design) files for a die, the cost typically ranges from $50 to $100 per hour.

A simple die might take between 10–20 hours of design. A complex progressive die might take 40–80 hours or more to design. It is also good practice to include a DFM (Design for Manufacturability) review when estimating the stamping die cost. A DFM review is used when the part is designed in a way that ensures the parts can be made in a cost-effective and reasonable manner for stamp use; this could lead to lower costs for you in the long run.

Prototyping & NRE (Non-Recurring Engineering) Costs

Prior to making production run parts, it is always suggested to produce prototypes, which will allow you to test and modify your dies to ensure that they produce the parts correctly. These non-recurring engineering (NRE) and prototyping costs will increase your overall stamping die price.

NRE are the one-time costs related to the design, development, and testing phase for a new product or component. While NRE can feel like an added cost, they are crucial to addressing issues up front, as rectifying errors during the development phase earlier will help reduce costly errors later during production runs.

How to Reduce Stamping Die Costs – Proven Best Tips

Want to save money on your stamping die project? There are a number of proven methods that can help reduce your overall costs.

Smart Metal Choices

You can save money by choosing your metal wisely. If your part does not need to have very high corrosion resistance properties, use galvanized steel and not the more expensive stainless steel. Also, keep an eye on metal prices; they can change. If you can, try to buy your material when prices are low. This smart approach helps your budget.

Simplify Tooling Requirements

Simpler designs mean simpler, cheaper dies for you. For example, if you change square holes to round holes, you can save costs! Round holes can be machined more easily, and save costs with tooling. Use standard, off-the-shelf die sets if possible. These don’t need custom manufacturing, which cuts both cost and how long it takes.

Optimize Part Design

The design of your part directly affects the complexity and cost of your die. For example, if you have at least the bend radius of your material thickness, you can reduce the number of steps during stamping, and save money. Also, consider combining several small parts into one larger stamped piece. This means you’ll only need one die, which simplifies production and lowers your tooling costs.

Improve Part Layout on the Strip

How you arrange your parts on the metal strip before stamping can save you a lot on material. A smart layout, called “tight nesting,” can help you get more parts from each strip. This can cut your material costs by 5-7% and significantly lower the cost per part. Many manufacturers use special software to find the most efficient layout for you.

Leverage Production Volume

Ordering more parts at once can really lower your stamping die price. If you can, give your manufacturer a yearly forecast and order that entire amount in one go. You could get 20% or more off the die price through volume discounts. Plus, if you have similar parts across different products, try to reuse common die parts to avoid building new dies.

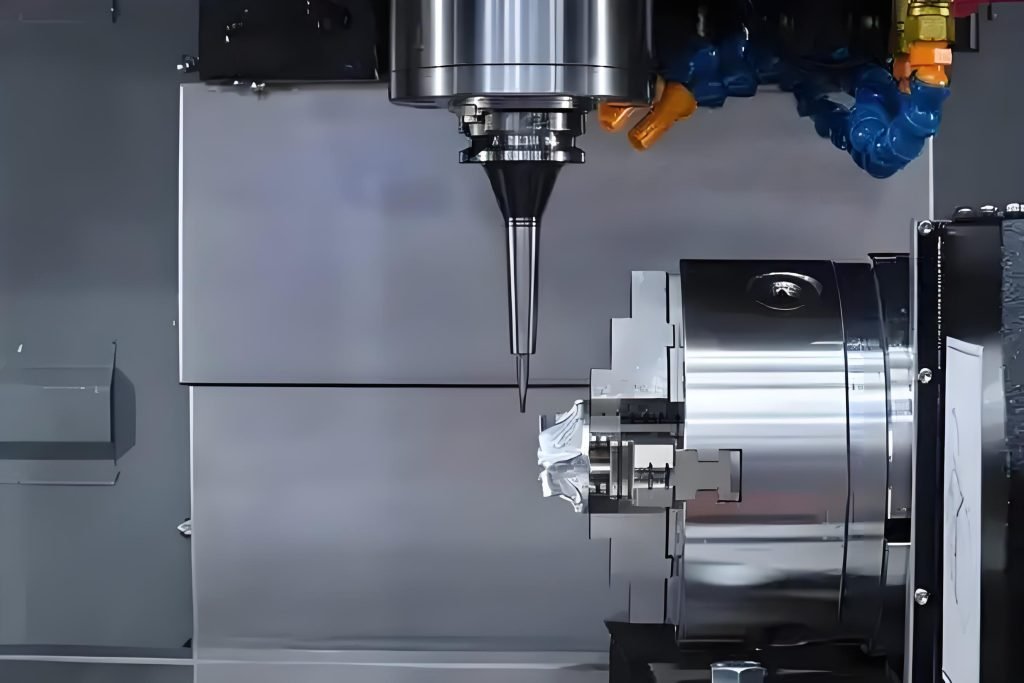

Pick an Experienced Manufacturer

The right manufacturer helps to keep costs down and control quality for you. A machine shop that has its own wire-EDM and CNC grinding enables quicker turnaround time, and less additional costs for outsourcing. When getting quotes, ask for a “turnkey” price. This means the quote includes everything: design, die build, part samples, and even maintenance, helping you avoid unexpected costs.

Is There Any Alternative to Metal Stamping?

While metal stamping is incredibly efficient for high-volume production, you might find that the stamping die cost is just too high for very low-volume runs or for prototyping. In such cases, there are indeed alternatives you can consider:

CNC Machining

If you need fewer than 200 parts and you’re machining thick blocks, CNC machining is a desirable alternative. CNC machining is also great when parts need incredibly tight tolerances, sometimes as small as ±0.01 mm. When you are looking to work on either complex designs, one-off pieces, or small batch products that you need extreme precision on, this is ideal.

3D Printing

3D printing, or additive manufacturing, simply means making parts layer by layer from a digital design. This method is excellent when you want to prototype quickly, need parts with complicated internal channels, or need parts that won’t have a lot of stress when in service. The method provides for an extraordinary amount of design freedom, but if you need to make metal parts in high volume, it won’t be financially practical.

Laser Cutting & Bending

If you are considering medium volumes or large panels and don’t want to incur the costs of a custom stamping die, combining laser cutting and bending is an excellent option. This approach yields more design flexibility and can, in certain cases, allow for faster production times for smaller production volumes. It gives you a good balance between precision and cost without the upfront expense of a dedicated die.

Metal Injection Molding (MIM)

Metal Injection Molding, or MIM, is a specialized production process that is best for full, high volumes and tiny, complex 3D shapes. MIM can be compared to plastic injection molding, but for metal components. This can be especially important if you need geometries with very intricate shapes that would be difficult or cost-prohibitive with other manufacturing methods.

| Method | Best For | Volume | Key Advantage |

| CNC Machining | Thick blocks, intricate designs | <200 parts | Extreme precision for small batches |

| 3D Printing | Prototypes, complex internal channels | Prototyping | Design freedom, no tooling needed |

| Laser Cutting | Medium volumes, large panels | Small-medium | No die cost, flexible for variations |

| MIM | Tiny, complex 3D shapes | High volume | Mass production of intricate small parts |

Choose Fecision for Precise yet Affordable Stamping Die

When you need a high-quality stamping die at a competitive price, Fecision delivers precision and affordability. Our dies, crafted with advanced CNC machining and wire EDM, ensure highly accurate parts with tight tolerances for large runs. We optimize materials and operations so you can get low costs for complex configurations.

With over 20 years as an ISO 9001:2015 certified industry leader, Fecision is the ideal source for progressive stamping die tooling solutions. With full CAD/CAM capacity, we can create custom die designs to suit your needs. In-house testing ensures top quality. Our progressive dies are capable of cycling up to 1500 strokes per minute with complex 3D shapes or precision flat parts.

We pride ourselves on being quick to respond and deliver on time. We optimize dies for speed, reliability, durability, and minimum downtime. This is crucial for reducing per-unit costs without compromising quality in mass production.

From small batches to mass production, Fecision adapts to your needs! Get a great stamping die price today at Fecision.