When designing products, understanding the properties of materials is crucial. One key property is the maximum stress a material can withstand while being stretched or pulled before breaking.

You need to know how different materials respond to force to ensure your product can withstand its intended use. The measure of this property, expressed in units like pounds per square inch (psi) or megapascals (MPa), is vital for selecting the right material.

Different materials behave differently under stress; some break sharply without deforming, while others can stretch further before failing. Understanding these differences is essential for product design and manufacturing.

Understanding Tensile Strength

Understanding tensile strength is essential for engineers and designers to ensure the structural integrity of their projects. Tensile strength refers to the maximum stress a material can withstand while being stretched or pulled before failing or breaking.

Definition and Basic Concepts

Tensile strength is typically measured through a tensile test, where a sample is subjected to increasing tension until it fractures. The ultimate tensile strength is the highest point on the stress-strain curve obtained from this test. It’s an important measure because it indicates the maximum stress a material can handle.

How Tensile Strength Differs from Other Material Properties

Tensile strength is distinct from other material properties like compressive strength, shear strength, and hardness. While compressive strength measures a material’s ability to withstand compressive forces, tensile strength focuses on its resistance to stretching forces. Additionally, tensile strength is related to but distinct from yield strength, which is the stress at which a material begins to deform plastically.

Understanding these differences is crucial for selecting the right materials for specific applications, ensuring that the chosen material can withstand the expected stresses and strains.

The Significance of Tensile Strength in Material Selection

The significance of tensile strength cannot be overstated in the context of material selection. Tensile strength is a critical property that determines a material’s ability to withstand tension without failing. This characteristic is crucial in various industries, from aerospace and automotive to consumer products and medical devices.

Role in Engineering and Manufacturing

In engineering and manufacturing, tensile strength plays a vital role in ensuring the safety and reliability of products. Engineers use tensile strength data to determine safety factors and predict how products will perform under various loading conditions. This information is critical in preventing product failures and ensuring safety in critical applications. The ultimate tensile strength of a material is particularly important, as it indicates the maximum stress a material can withstand before failing.

Understanding tensile properties also helps manufacturers select the most appropriate materials for their products. For instance, in the aerospace industry, materials with high tensile strength are preferred to minimize weight while maintaining structural integrity. The manufacturing process can also be influenced by tensile strength, as materials with high tensile strength may require specialized equipment or techniques.

Impact on Product Design and Performance

Tensile strength significantly impacts product design and performance. Designers must consider the tensile strength of materials when making decisions about material thickness, reinforcement needs, and structural configurations. A material’s tensile strength affects its durability, reliability, and overall performance throughout its lifecycle. For example, in the automotive industry, the tensile strength of steel used in vehicle bodies is crucial for ensuring passenger safety in the event of a collision.

By understanding the tensile properties of materials, designers can create products that are not only functional but also safe and durable. This knowledge enables them to push the boundaries of innovation while minimizing the risk of product failure. As a result, tensile strength remains a fundamental consideration in material selection and product design across various industries.

Types of Tensile Strength

Understanding the different types of tensile strength is essential for selecting the right material for your project. Tensile strength is not a single value, but rather it encompasses several important measurements that help engineers and designers predict how materials will behave under various loads.

Yield Strength

Yield strength is the amount of stress that a material can withstand before it begins to deform plastically. At this point, the material will no longer return to its original shape when the force is removed. Yield strength is a critical parameter in material selection, as it determines the maximum stress that can be applied without causing permanent deformation.

Ultimate Tensile Strength

Ultimate tensile strength (UTS) is the maximum stress that a material can withstand while being stretched or pulled before it begins to neck. UTS is an important measure of a material’s ability to resist failure under tension. It’s worth noting that some materials may not exhibit a clear necking behavior, in which case UTS represents the maximum stress before fracture.

Breaking Strength

Breaking strength, also known as fracture strength, is the stress at which a material actually breaks or fractures under tension. This value is typically measured on a stress-strain curve and represents the point of material failure. Breaking strength is crucial for understanding the limits of a material’s performance.

These three types of tensile strength are related but distinct, and understanding their differences is vital for material selection and design. By examining yield strength, ultimate tensile strength, and breaking strength together, you can gain a comprehensive understanding of a material’s behavior under tensile stress.

Calculating and Measuring Tensile Strength

Understanding how to calculate and measure tensile strength is crucial for material selection and engineering applications. Tensile strength is defined as the maximum stress a material can withstand while being stretched or pulled before failing or breaking. This property is essential in determining the suitability of a material for a specific application.

Tensile Strength Formulas and Calculations

The fundamental formula for calculating tensile strength is the maximum force applied divided by the original cross-sectional area. This calculation provides the ultimate tensile strength (UTS) of a material, which is a critical parameter in material science. You can calculate UTS using the formula: UTS = Maximum Force / Original Cross-Sectional Area.

Units of Measurement

Tensile strength is measured in units of force per unit area. The International System of Units (SI) uses pascals (Pa) or megapascals (MPa), while the United States customary unit is pounds per square inch (psi). Understanding these units and how to convert between them is vital for international projects and standards compliance.

Stress-Strain Curves and Their Interpretation

Stress-strain curves are graphical representations of a material’s response to tensile stress. By interpreting these curves, you can identify key points such as the elastic limit, yield point, ultimate tensile strength, and breaking point. This information is crucial for understanding a material’s behavior under different loads and conditions.

Tensile Strength Testing Methods

Tensile testing is a widely used method to determine the strength and deformation behavior of materials under tension. This testing involves taking a small sample with a fixed cross-sectional area and pulling it with a tensometer at a constant strain rate until the sample breaks.

Standard Testing Procedures

Standardized tensile testing procedures are crucial for ensuring consistent and comparable results. For plastics, ASTM D638 is commonly used, while for metallic materials, ASTM E8 is the standard. These procedures outline the preparation of test specimens with specific dimensions and shapes. The rate of force application is also critical, as it affects test results, and standardized testing speeds are essential.

You’ll find that extensometers and strain gauges play a vital role in measuring deformation during testing, generating accurate stress-strain curves. Different gripping methods are used for various materials to prevent slippage and ensure accurate load application.

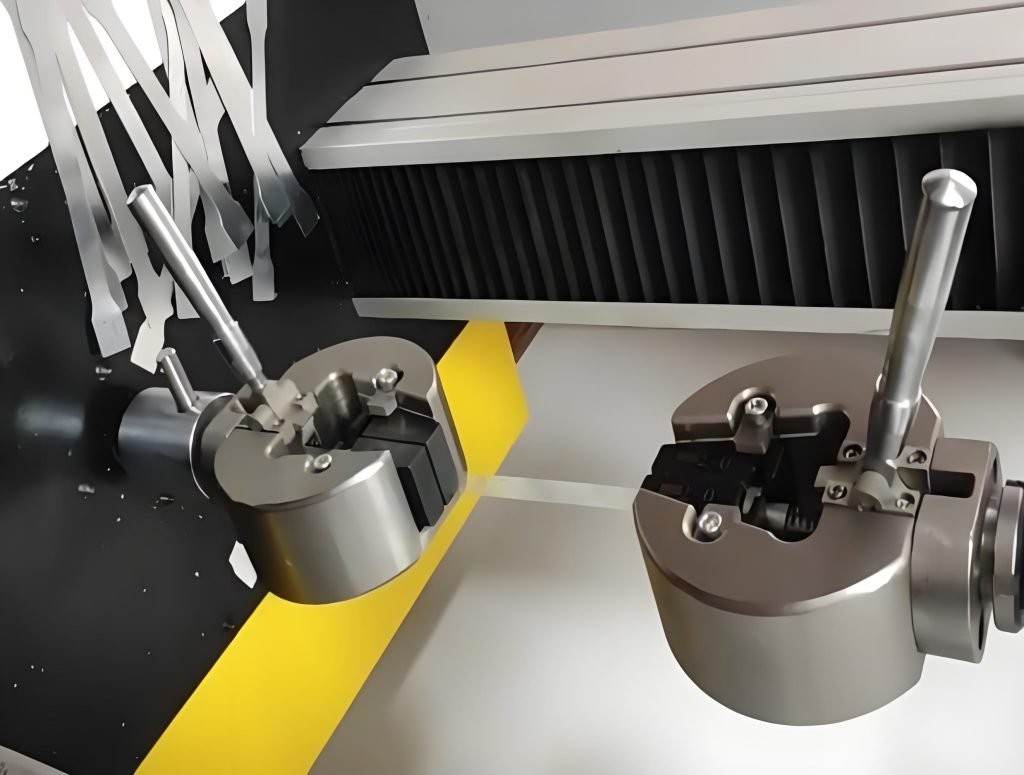

Equipment Used in Tensile Testing

Tensile testing machines, also known as universal testing machines, are used to apply force to the test specimen. These machines are equipped with load cells to measure the force applied and extensometers to measure deformation. The choice of gripping method depends on the material being tested, and environmental conditions like temperature and humidity are controlled to prevent their impact on test results.

Understanding how to interpret test reports and recognizing common sources of error in tensile testing are also crucial for accurate material characterization.

Tensile Strength of Common Materials

Different materials exhibit a broad range of tensile strengths, which is essential knowledge for engineers and designers. The tensile strength of a material is a critical factor in determining its suitability for various applications.

Metals and Alloys

Metals and alloys are known for their high tensile strength, making them suitable for structural applications. For instance, structural ASTM A36 steel has a yield tensile strength of 250 MPa and an ultimate tensile strength ranging from 400 to 550 MPa. Aluminum alloy 6061-T6 is another example, with a yield strength of 241 MPa and an ultimate tensile strength of 300 MPa. These materials are widely used in construction and manufacturing due to their strength-to-weight ratio.

Polymers and Plastics

Polymers and plastics exhibit different tensile behaviors compared to metals, typically showing greater elasticity but lower ultimate tensile strength. High-density polyethylene (HDPE), for example, has a yield strength of 26-33 MPa and an ultimate tensile strength of 37 MPa. While their tensile strength is generally lower than that of metals, polymers are valued for their versatility and resistance to corrosion.

Natural Materials and Composites

Natural materials and composites also display a range of tensile strengths. Carbon fiber, for instance, has an ultimate tensile strength of 1,600 MPa for laminates and 4,137 MPa for fibers alone, making it ideal for high-performance applications. Other natural materials like glass and concrete have tensile strengths of 41 MPa and 2-5 MPa, respectively. Understanding these properties is crucial for selecting the appropriate material for specific uses.

Factors Affecting Tensile Strength

To ensure the durability and performance of your materials, it’s essential to understand the factors that impact tensile strength. The tensile strength of a material is influenced by a combination of intrinsic properties and external conditions.

Temperature and Environmental Conditions

Temperature significantly affects tensile strength, with most materials becoming weaker at higher temperatures and some becoming brittle at lower temperatures. Environmental factors like humidity, UV exposure, and chemical exposure can also degrade tensile properties over time, particularly in plastics.

Material Composition and Structure

Material composition, including additives, fillers, and molecular weight in plastics, directly influences tensile strength. Microstructural features like grain size in metals, crystallinity in polymers, and fiber orientation in composites also affect tensile performance.

Manufacturing Processes and Quality Control

Manufacturing processes like molding, extrusion, and heat treatment can enhance or reduce tensile strength through their effects on material structure. Processing parameters such as cooling rate, pressure, and temperature profiles during manufacturing affect the final tensile properties. Common defects introduced during manufacturing, such as voids and inclusions, can significantly reduce tensile strength.

Conclusion: The Future of Tensile Strength in Material Science

In the world of material science, tensile strength stands out as a critical factor that influences the success of product design and development. As you’ve learned, understanding tensile strength is essential for making informed material selection decisions.

The future of tensile strength in material science looks promising, with emerging trends like nanomaterials, metamaterials, and bioinspired designs pushing the boundaries of ultimate tensile strength. Computational modeling and simulation are also transforming how engineers predict and optimize tensile properties.

As new materials and manufacturing processes emerge, knowledge of tensile strength will remain crucial. You’ll need to balance tensile strength with other properties to ensure holistic material selection. With the demand for lightweight, high-strength materials driving innovation, the importance of tensile strength will only continue to grow.