Are you interested in EDM? This widely used and crucial manufacturing technology has applications across industries like medical, aerospace, defense, automation, and energy production. It enables the production of complex geometries and high-precision parts, even in hardened materials.

For critical components in high-end applications—whether simple mechanical parts or intricate 3D shapes—understanding EDM’s unique capabilities is essential for making informed decisions in your next project.

This article explores all types of electric discharge machining, their applications, and tips for choosing the best EDM machine for your needs.

The 3 Main Types of Electric Discharge Machining

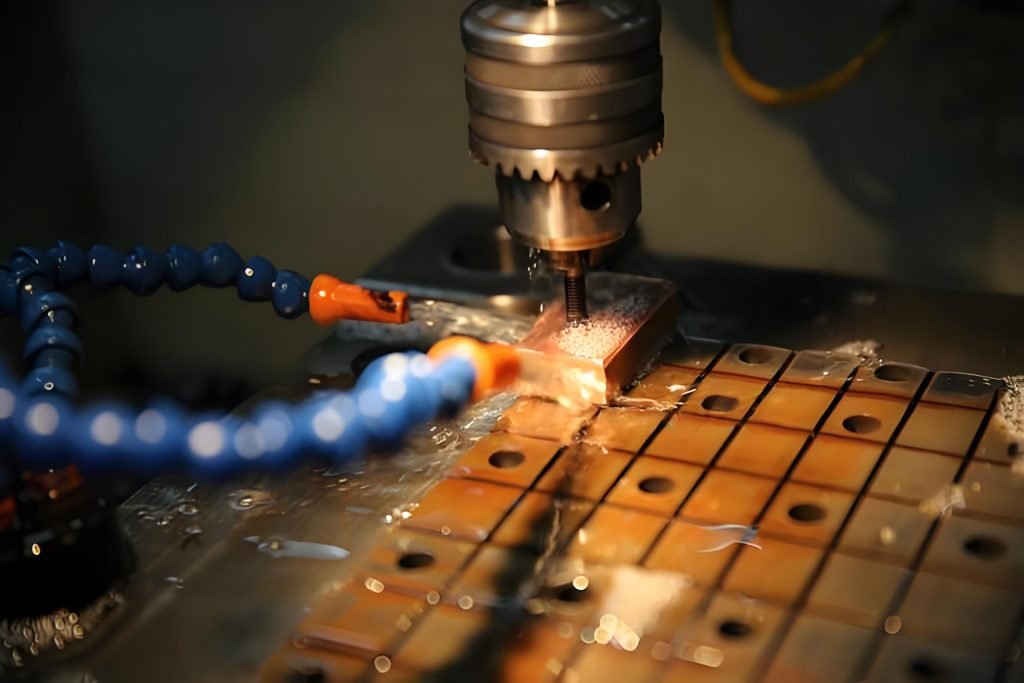

Electrical Discharge Machining (EDM) encompasses three primary techniques, each tailored for precision machining of conductive materials.

Wire EDM

Wire EDM, also known as wire cutting, employs a fine wire (0.05–0.35 mm in diameter) as an electrode to erode material through controlled spark discharges. This method excels in cutting hardened materials and is widely used in aerospace (aircraft components, stamping dies), medical devices, and extrusion mold production. The process operates along the X, Y, and Z axes, with the ability to achieve angled cuts by adjusting wire alignment. Advanced systems incorporate rotational axes, enabling complex geometries in five-axis configurations.

Sinker EDM

Sinker EDM utilizes a custom-shaped electrode to create precise cavities or inverse geometries in the workpiece. Ideal for mold manufacturing—such as injection molds and die-casting—it addresses limitations of CNC machining by producing sharp internal corners and fine details without mechanical stress. Beyond molds, it’s valued in aerospace and medical industries for its ability to deliver smooth, high-tolerance surfaces. While less precise than CNC in some applications, its non-contact process ensures superior surface integrity for delicate components.

Hole-drilling EDM

Specializing in micro-hole fabrication, hole-drilling EDM produces exceptionally straight, deep, or small-diameter holes (as fine as 0.0015 inches) with consistent accuracy. Critical for turbine blade cooling channels, scientific instruments, and repairing broken tools, this method eliminates the need for post-processing by delivering smooth, ready-to-use holes—even in hardened or brittle materials. Its capability to drill blind or through holes with high aspect ratios makes it indispensable for industries demanding micron-level precision.

EDM Type Comparison Table

The following table compares key characteristics of various electrical discharge machining (EDM) processes.

| Type | Wire EDM | Sinker EDM | Hole Drilling EDM |

| Precision | High | High | Moderate |

| Surface finish | Smooth | Smooth | Good |

| Speed | Moderate | Slowly | Fast |

| Shape | Complex shapes and intricate patterns | Complex shapes based on customized electrodes | Mainly used for drilling at different depths. |

| Electrode Type | Thin wire | Custom electrodes | tubular |

| Electrode Wear | low | High | Moderate |

| Application | Electronics, jewelry, medical, aerospace | Tools and molds, aerospace, plastics | Aerospace, preprocessing of wire EDM, and automobiles |

How to Choose the Right EDM Type?

Selecting the optimal EDM process requires careful evaluation of multiple technical and operational factors. These considerations directly impact which EDM method will deliver the best results for your specific application. An improper selection could compromise part quality, production efficiency, and overall project economics.

Tip for Choosing EDM Machining

Follow these key steps to identify the optimal EDM process:

- Clarify project requirements

Before selecting an EDM process, thoroughly define your project specifications by evaluating key factors such as material complexity, precision tolerances, production volume, and surface finish quality.

- Study and compare different types of EDM

When evaluating EDM processes, it’s essential to research and compare the various available techniques – including wire EDM, sinker EDM, and hole-drilling EDM – as each method offers distinct advantages and limitations that must be carefully assessed based on working principles, application scope, and operational constraints.

- Evaluate material compatibility

Selecting the appropriate EDM technique requires careful assessment of material compatibility, as different methods are optimized for specific material properties. A thorough evaluation should consider key characteristics, including electrical conductivity, hardness, and thermal properties, to ensure optimal machining performance and precision in the final product.

- Consider the complexity and geometry of the metal parts

The selection of an EDM process must account for the part’s geometric complexity, as different techniques excel at specific applications; wire EDM achieves precise cuts for intricate contours, while sinker EDM better accommodates mold cavities and grooves. A thorough evaluation of each method against your design specifications ensures optimal process selection.

- Evaluate the precision and tolerance requirements

The selected EDM technique must align with your project’s precision and tolerance specifications, as capabilities vary significantly between processes. Certain methods maintain exceptionally tight tolerances, while others are better suited for rough machining operations. Your final selection should be determined by the exact accuracy demands of your specific application.

- Evaluate the production volume and production rate

When selecting an EDM technique, production volume and efficiency requirements must be carefully assessed, as certain methods offer high throughput for mass production while others are better suited for prototyping or low-volume manufacturing. The evaluation should include analysis of each process’s operational speed, automation potential, and overall production efficiency to ensure optimal alignment with your output demands.

- Consider cost factors

Cost represents a critical consideration when selecting an EDM process, requiring a comprehensive evaluation of equipment expenses, tooling costs, electrode wear rates, and maintenance demands. Additionally, the long-term operational impact of your chosen technique must be assessed to ensure overall project viability and cost-effectiveness.

- Seek professional suggestions

When uncertain about the most suitable EDM process, consulting an industry professional is recommended, as they can offer valuable insights and recommendations based on specialized knowledge and practical experience with various electrical discharge machining techniques.

- Perform testing and evaluate results

Prior to finalizing your EDM selection, conducting sample tests is essential to assess critical factors, including surface finish quality, dimensional accuracy, material removal rate, and overall part quality. This validation process confirms the technique’s suitability for your specific project requirements.

When to Choose Wire EDM?

Wire EDM is specifically designed to machine hardened materials and execute intricate, complex designs with exceptional precision. This method is particularly suitable for projects requiring:

- High-precision, high-accuracy cutting

- Small incisions or well-defined grooves

- Complex shapes or fine patterns

Common applications include the manufacture of critical metal components in aerospace, electrical, and medical industries.

When to Choose Sinker EDM?

Sinker EDM (also known as Ram EDM or Plunge EDM) is the ideal process for creating complex three-dimensional shapes in workpieces. This technique is particularly suitable for:

- Projects requiring precise grooves or molds

- Applications demanding fine details in hard materials

- Creating intricate 3D forms

When to Choose Hole Drilling EDM?

Hole drilling EDM offers a fast and efficient solution for creating precision holes in hardened metals. This method is particularly suitable for:

- Rapid drilling in hard materials

- Gun drilling applications

- Pre-treatment for wire EDM operations

Common industrial applications include fuel system components in aerospace and automotive manufacturing.

Precision EDM Services for Your Project Needs

EDM (Electrical Discharge Machining) is a highly efficient manufacturing technology that enables the production of high-precision components. This article explores various EDM techniques—including Wire EDM, Sinker EDM, and Hole Drilling EDM—and provides guidance on selecting the optimal method for your application.

Looking for a reliable EDM service provider? Fecision is your ideal partner, offering:

- Versatile manufacturing solutions, including EDM, CNC machining, and more

- Rapid lead times without compromising quality

- Expert engineering team with decades of experience in precision machining and design optimization

- Extensive material selection tailored to your project requirements