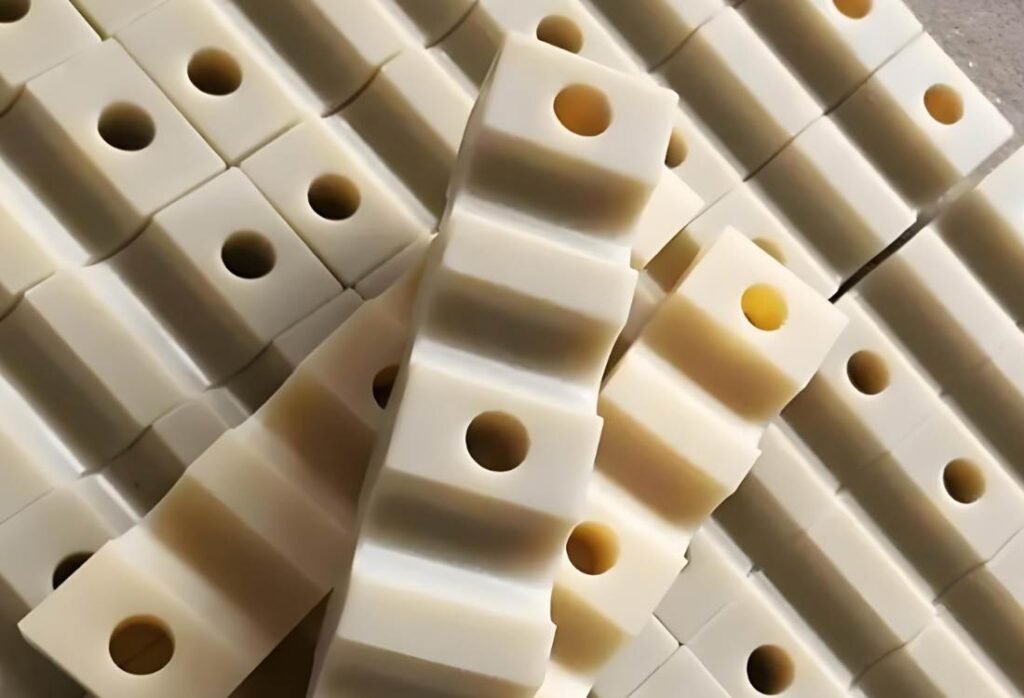

PA (Nylon) Injection Molding Services

PA (Nylon) injection molding delivers exceptional strength, durability, and versatility for critical components across industries. Our specialized services transform this remarkable engineering thermoplastic into precision parts that outperform and outlast alternatives. Whether you need automotive components, industrial machinery parts, or consumer products, our expertise in nylon injection molding ensures optimal results for your most demanding applications.

Precision

Durability

High-performance

Overview of PA Material

What is Nylon (Polyamide) Plastic?

Nylon, technically known as polyamide (PA), is a semi-crystalline thermoplastic polymer characterized by amide bonds (-NH-CO-) in its molecular structure. First developed by DuPont in the 1930s, nylon has evolved into one of the most versatile engineering plastics available today.

This remarkable material bridges the gap between conventional plastics and metals, offering an ideal balance of mechanical strength, chemical resistance, and processability. Its unique properties make it particularly well-suited for injection molding processes, where complex geometries and precise dimensions are essential.

High Strength

Exceptional tensile strength and toughness

Wear Resistance

Excellent abrasion and friction resistance

Low Friction

Self-lubricating with smooth sliding properties

Types of Molded Nylon Materials

| Nylon Type | Key Properties | Best Applications |

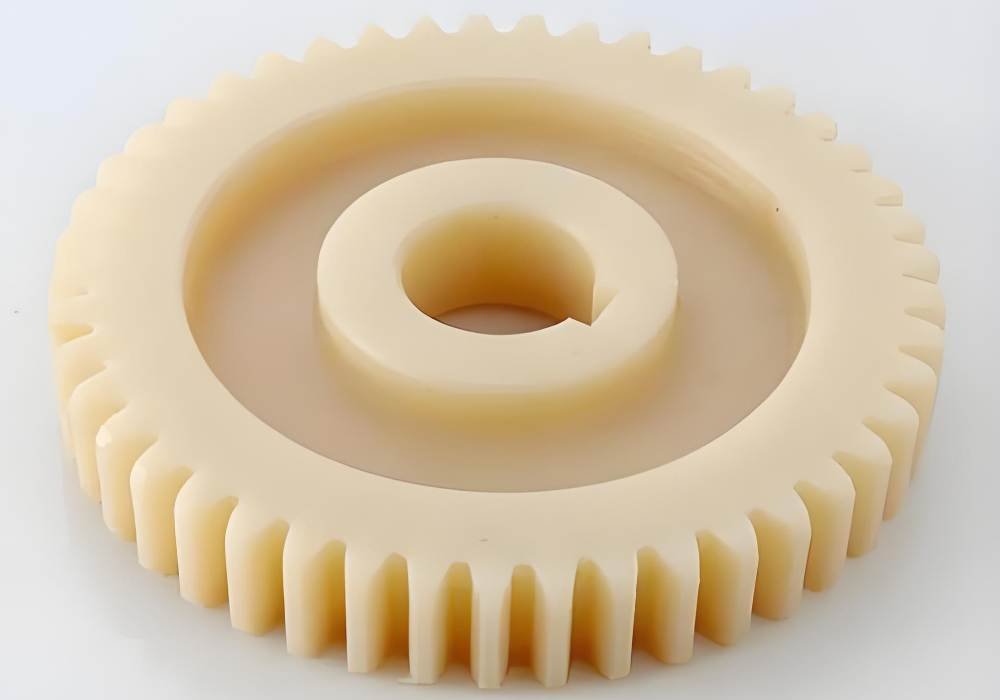

| PA6 (Nylon 6) | Good toughness, lower melting point (220°C), higher moisture absorption | Gears, bearings, automotive parts, electrical components |

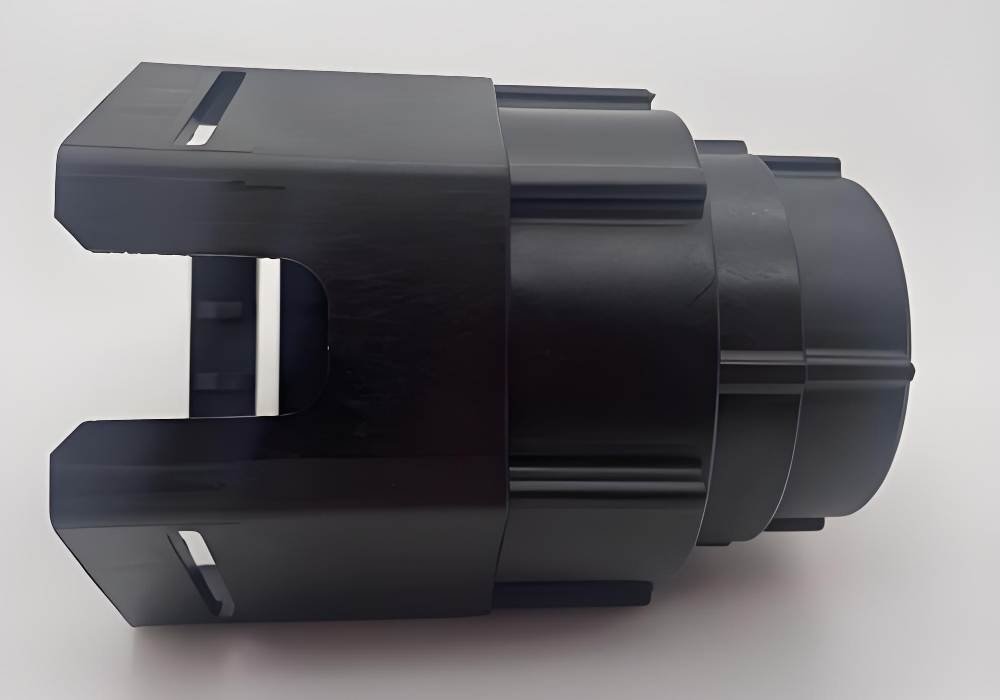

| PA66 (Nylon 66) | Higher strength and heat resistance (260°C melting point), better dimensional stability | Under-hood automotive components, electrical housings, industrial parts |

| PA6 + GF30 | 30% glass fiber reinforcement, increased rigidity and dimensional stability | Structural components, load-bearing parts, metal replacements |

| PA12 | Lower moisture absorption, excellent chemical resistance, more flexible | Fuel lines, pneumatic tubing, cable ties, sporting goods |

| PA11 | Bio-based option, excellent impact resistance, low moisture absorption | Sporting goods, consumer products, flexible components |

Not Sure Which Nylon Type Is Right for Your Project?

Our material experts can help you select the optimal PA (Nylon) formulation for your specific application.

Properties of Nylon Plastic (PA)

Nylon's exceptional combination of properties makes it an ideal choice for demanding applications where other plastics might fail.

Understanding these characteristics is crucial when considering PA (Nylon) injection molding for your projects.

Mechanical Properties

- High tensile strength (45-80 MPa)

- Excellent fatigue resistance

- Superior wear resistance

- Good impact resistance

- Low coefficient of friction

Thermal Properties

- High melting point (220-265°C)

- Continuous use temperature up to 150°C

- Thermal conductivity: 0.25-0.35 W/(m·K)

- Coefficient of thermal expansion: 80-100 × 10⁻⁶/°C

Chemical Properties

- Resistant to fuels, oils, and many solvents

- Good resistance to weak acids

- Excellent resistance to alkalis

- Resistant to hydrocarbons

Other Properties

- High moisture absorption (2-8%)

- Good electrical insulation

- Natural translucent white appearance

- Easily colorable

Nylon Injection Molding Process

The PA (Nylon) injection molding process requires specialized knowledge and equipment to achieve optimal results.

Our proven methodology ensures consistent, high-quality parts that meet your exact specifications.

Material Preparation

Nylon pellets are thoroughly dried (typically at 80-100°C for 2-4 hours) to remove moisture that could cause hydrolysis during processing.

Packing

Additional material is packed into the mold to compensate for shrinkage as the part cools.

Melting

The dried pellets are fed into the injection molding machine where they're heated to 230-290°C (depending on the specific nylon type).

Cooling

The part cools within the mold until it solidifies, with mold temperature typically maintained between 80-120°C for optimal crystallinity.

Injection

The molten nylon is injected into the mold cavity at controlled pressure and speed to ensure complete filling.

Ejection & Post-Processing

The finished part is ejected from the mold. If required, parts undergo secondary operations such as trimming, assembly, or surface treatments.

Nylon Injection Molding Additives

Various additives can enhance nylon's properties for specific applications. Our material expertise helps you select the optimal formulation for your unique requirements.

| Glass Fibers (15-50%) | Increases strength, stiffness, dimensional stability, and heat resistance | Structural components, metal replacements, under-hood automotive parts |

| Carbon Fibers | Enhances strength, stiffness, and provides electrical conductivity | EMI shielding components, high-performance structural parts |

| Flame Retardants | Improves fire resistance and reduces flammability | Electrical housings, connectors, consumer electronics |

| UV Stabilizers | Protects against degradation from sunlight exposure | Outdoor equipment, automotive exterior parts |

| Impact Modifiers | Enhances toughness and low-temperature impact resistance | Safety components, consumer products, cold-environment applications |

| Lubricants (PTFE, Silicone) | Reduces friction and improves wear resistance | Gears, bearings, sliding components |

Critical Process Parameters

Temperature Control

PA6 typically requires barrel temperatures of 220-260°C, while PA66 needs higher temperatures of 260-290°C. Mold temperature affects crystallinity, surface finish, and mechanical properties.

Moisture Management

Nylon's hygroscopic nature necessitates thorough drying before processing. Moisture content should be below 0.2% to prevent surface defects, voids, and degradation of mechanical properties.

Challenges with Nylon Injection Molding

Common Challenges

- Moisture Sensitivity: Nylon absorbs atmospheric moisture, which can cause processing issues and reduced mechanical properties.

- High Shrinkage: Nylon has a relatively high shrinkage rate (1-2%), which can affect dimensional accuracy.

- Warpage: Differential cooling and crystallization can cause parts to warp, especially in thin-walled sections.

- Mold Adhesion: Nylon can stick to mold surfaces, making part ejection difficult without proper design considerations.

- Thermal Degradation: Excessive processing temperatures can degrade the polymer, reducing mechanical properties.

How We Overcome Challenges

- Advanced Drying Protocols: Our specialized drying equipment and validated procedures ensure optimal moisture removal before processing.

- Precision Mold Design: We compensate for nylon’s shrinkage characteristics through sophisticated mold design and engineering.

- Optimized Process Parameters: Our process engineers fine-tune temperature, pressure, and cooling profiles specifically for each nylon formulation.

- Material Selection Expertise: We help you select the ideal nylon grade based on your application requirements and environmental conditions.

- Quality Control Systems: Our comprehensive inspection protocols catch and correct potential issues before they affect your parts.

Nylon Injection Molding Applications

Industries We Serve

PA (Nylon) injection molded components excel across diverse industries due to their exceptional combination of properties. Our expertise spans all these applications, ensuring optimal material selection and processing for your specific needs.

Automotive

Under-hood parts

Interior trim components

Electrical connectors

Gears and bearings

Consumer Products

Tool housings

Sports equipment

Furniture components

Electronic device housings

Industrial

Conveyor parts

Electrical housings

Fasteners and fittings

Machinery components

Medical

Device housings

Laboratory equipment

Sterilizable components

Aerospace

Lightweight brackets

Wire management systems

Non-structural elements

PA (Nylon) Injection Molding with Precision

Material Expertise

Our materials specialists help you select the optimal nylon formulation for your specific application requirements, balancing performance, processability, and cost considerations.

Design Optimization

Our engineering team provides design for manufacturability (DFM) feedback to optimize your parts for nylon injection molding, ensuring quality while minimizing costs.

Precision Tooling

We design and manufacture high-precision molds specifically optimized for nylon processing, with proper venting, cooling, and ejection systems for flawless parts.

Quality Assurance

Our comprehensive quality control system includes in-process monitoring, dimensional verification, and performance testing to ensure every part meets your specifications.

Production Scalability

From prototypes to high-volume production, our flexible manufacturing capabilities scale to meet your changing needs without compromising quality.

Value-Added Services

We offer assembly, secondary operations, custom packaging, and logistics support to provide a complete manufacturing solution for your nylon components.

PA (Nylon) Injection Molding FAQs

Need to Discuss Nylon Injection Molding Project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Start Your PA (Nylon) Injection Molding Project Today

Contact our team to discuss your requirements and discover how our expertise can bring your designs to life with precision and efficiency.