Are you struggling to decide between Invar and Kovar for your precision engineering projects? Choosing the right material is crucial for achieving optimal performance and dimensional stability.

Both alloys are renowned for their low thermal expansion properties, making them ideal for applications in electronics, aerospace, and other industries where precision is paramount.

Understanding the distinct advantages and characteristics of these materials will help you make an informed decision. This comprehensive guide will explore the differences in their composition, physical properties, and machinability, ensuring you select the best alloy for your specific needs.

Understanding Low Thermal Expansion Alloys

Precision manufacturing often requires materials that can withstand temperature fluctuations without compromising their structural integrity. You need materials that maintain their dimensional stability across varying temperature conditions, making low thermal expansion alloys invaluable in this context.

The Importance of Thermal Stability in Manufacturing

Thermal stability is critical in manufacturing processes where even microscopic dimensional changes can lead to component failure, particularly in electronics, aerospace, and scientific instrumentation. You rely on materials with a low coefficient of thermal expansion to ensure the reliability and performance of your products.

Key Properties for Precision Engineering

The key properties that define low thermal expansion alloys include their thermal behavior, strength, corrosion resistance, and machinability. You look for materials that offer a combination of high strength, dimensional stability, and resistance to corrosion, making them suitable for specific engineering challenges.

Understanding the fundamental characteristics of these alloys provides the foundation for making informed comparisons between different materials, such as Invar and Kovar, in subsequent sections.

What is Kovar?

Kovar, also known as ASTM F15, is an iron-nickel-cobalt alloy that has gained popularity for its compatibility with borosilicate glass. This alloy is specifically engineered to match the thermal expansion coefficient of borosilicate glass, making it invaluable for glass-to-metal seals in electronic components.

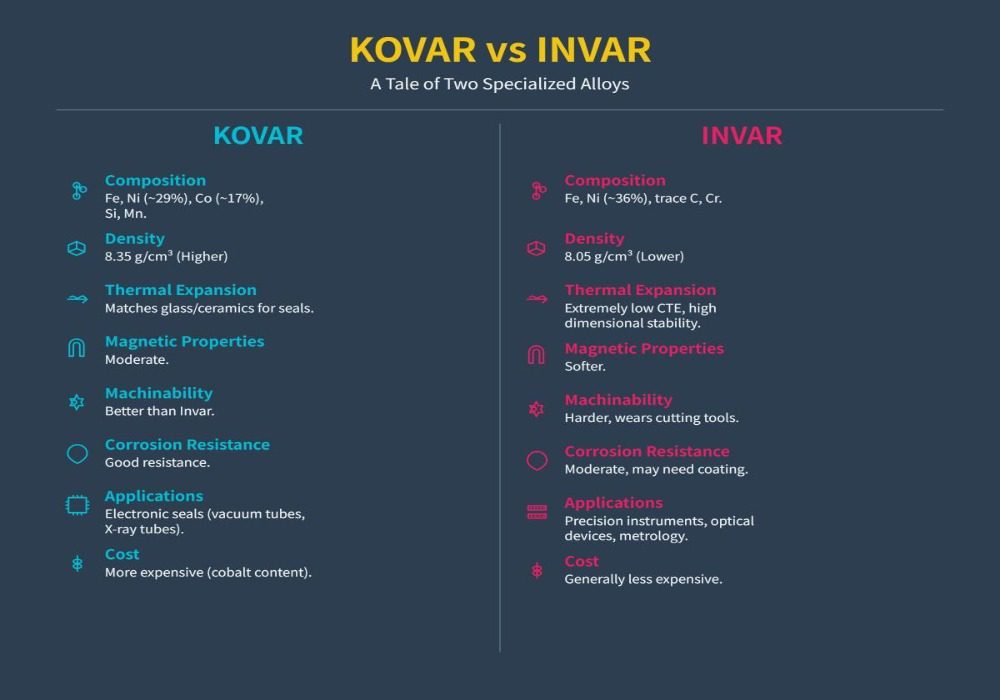

Composition and Physical Properties

The composition of Kovar typically includes 28.5-29.5% nickel, 16.8-17.8% cobalt, with the remainder being iron and trace elements. This unique composition gives Kovar a thermal expansion coefficient of approximately 4.57 x 10^-6 m/mK, closely matching that of borosilicate glass. Kovar’s physical properties, such as its melting point of 1430°C and density of 8800 kg/m³, make it particularly suited for electronic packaging applications.

Unique Characteristics of Kovar

Kovar’s exceptional compatibility with glass and ceramics, combined with its good thermal shock resistance and chemical corrosion resistance, makes it an ideal material for vacuum-sealed devices and airtight containers. Its ability to be developed into complex shapes with tight tolerances further enhances its suitability for demanding applications.

Machinability and Processing Considerations

When machining Kovar, you benefit from its good workability using oil-based lubricants and water-soluble cutting fluids. Special attention must be paid to its forming processes, including cold or hot rolling, pressing, and forging techniques, to achieve the desired properties and dimensions.

What is Invar?

In the realm of precision engineering, one alloy stands out for its ability to resist thermal expansion: Invar. You’re about to explore what makes Invar an ideal choice for applications that demand high precision and stability across a wide range of temperatures.

Composition and Physical Properties

Invar is an iron-nickel alloy, also known as FeNi36, composed of approximately 36% nickel and 64% iron. Its physical properties include a melting point of 1425°C and a density of 8100 kg/m³. The alloy’s most distinctive characteristic is its remarkably low coefficient of thermal expansion, measuring just 1.2 x 10^-6 m/mK.

Distinctive Features of Invar

Invar’s near-zero expansion over a wide temperature range from -250°C to 200°C makes it invaluable in applications requiring exceptional dimensional stability. You’ll find Invar particularly useful in precision scientific instruments, telescope mirrors, laser assemblies, and cryogenic equipment where even microscopic dimensional changes could compromise performance.

Processing Challenges and Solutions

Processing Invar presents unique challenges due to its hardness and toughness. To maintain its valuable properties, specialized machining techniques are required, along with precise temperature control during manufacturing and careful consideration of strain rates. By adopting these strategies, you can ensure that Invar components meet the high standards required for precision engineering applications.

Invar vs Kovar: Key Differences and Applications

When it comes to precision engineering, understanding the differences between Invar and Kovar is crucial for selecting the right material for your applications. Both alloys have unique properties that make them suitable for different uses.

Thermal Expansion Coefficient

The most significant difference between Invar and Kovar lies in their thermal expansion coefficients. Invar has a coefficient of 1.2 x 10^-6 m/mK, while Kovar’s is 4.57 x 10^-6 m/mK. This difference makes Invar ideal for applications requiring dimensional stability, such as precision instruments and aerospace components.

Strength, Density, and Melting Point

In terms of physical properties, Kovar has a slightly higher density (8800 kg/m³) and melting point (1430°C) compared to Invar (8100 kg/m³ and 1425°C). These differences, along with their distinct strength characteristics and magnetic behaviors, influence their suitability for various applications.

Cost Considerations and Value Analysis

Generally, Kovar is more cost-effective than Invar due to its manufacturing process and composition. However, the cost difference is often justified by Invar’s exceptional thermal stability in applications where precision is paramount.

Applications

Both alloys have distinct applications based on their properties. Invar is used in precision measuring equipment, scientific instruments, and aerospace components where dimensional stability is critical. Kovar, on the other hand, is preferred for glass-to-metal seals, vacuum tubes, and high-temperature components.

Electronic and Vacuum Applications

In electronic applications, Kovar dominates in glass-to-metal seals for vacuum tubes, transistors, and integrated circuit packaging due to its compatible thermal expansion properties. Invar, while not typically used for glass-to-metal seals, is valued in precision measuring equipment and scientific instruments.

Aerospace and Scientific Instruments

In the aerospace sector, Invar 36 is utilized for manufacturing orbital control and orientation systems for spacecraft, as well as components for engines and turbines, due to its dimensional stability. Kovar 29 is used for high-temperature components like turbine blades and combustion chambers, leveraging its high-temperature resistance.

Conclusion: Choosing the Right Alloy for Your Precision Engineering Needs

The decision between Invar and Kovar hinges on several key factors that are critical to your application’s performance. To make an informed choice, consider your project’s specific requirements, including thermal stability needs, operating environment, and budget constraints.

For applications requiring glass-to-metal seals or compatibility with ceramics, Kovar’s matched expansion coefficient is advantageous. In contrast, projects demanding dimensional stability across temperature ranges benefit from Invar’s near-zero expansion properties.

Fecision offers expert manufacturing capabilities for both Invar and Kovar components, ensuring you receive the ideal material for your specific engineering challenges. With precision machining that preserves each alloy’s unique properties, Fecision is a reliable partner for your precision engineering needs.