You need a mold that maintains quality while saving time and money. That’s why many manufacturers prefer aluminum tooling. Compared to steel molds, they are quick, inexpensive, and simple to machine. Aluminum is a popular choice among businesses due to its low production costs and speed.

Because these molds cool more quickly, cycle times are shortened, and efficiency is increased. Parts can be produced fast and without delays. Metal molds provide the speed you need in competitive industries. This article covers benefits, comparisons, and proper aluminum injection mold construction for your projects.

What Is An Aluminum Injection Mold?

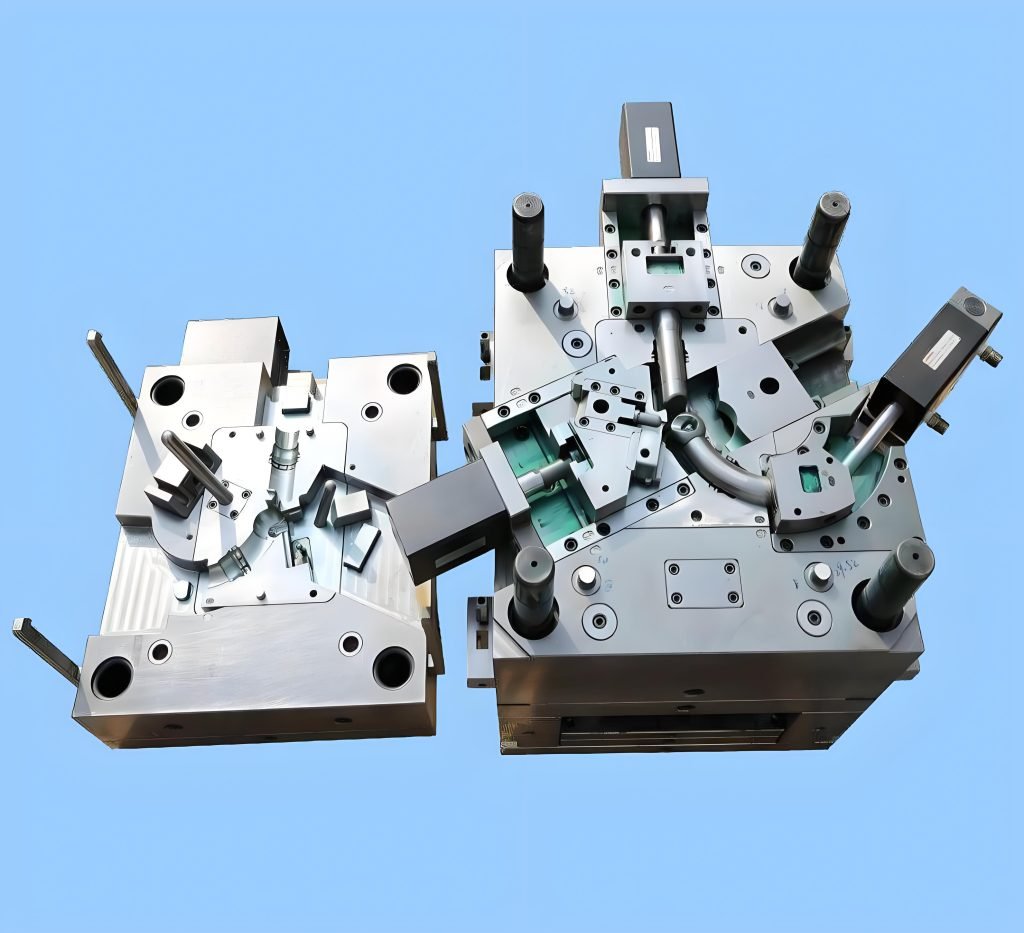

One tool for making plastic parts is an aluminum injection mold. It maintains pressure on molten plastic until it cools and solidifies. The mold cavity determines the final shape and dimensions of the part. These molds are essential for the rapid and efficient production of precise, consistent plastic components.

Role In Plastic Injection Molding

Injection molding relies heavily on aluminum molds. During manufacturing, they form the plastic into precise shapes. The plastic takes the shape of the cavity as it is injected into the mold. The part is ejected when the mold opens after it has cooled. Every molded part is ensured to be accurate and repeatable thanks to this process.

Why Use Aluminum Instead Of Other Metals

Aluminum’s ease of machining and quick cooling make it a popular choice among manufacturers. Because aluminum conducts heat more efficiently than steel, it reduces production times. Additionally, their production costs are lower. It offers an economical and effective solution for prototypes or low-volume production, without compromising the quality of molded parts.

Why Choose Aluminum Molds For Injection Molding?

You want to cut expenses without compromising on quality. Because aluminum molds are less expensive to manufacture than steel molds, your investment will be much lower. Additionally, they improve time-to-market by delivering parts more quickly. Another benefit is flexibility. They are ideal for projects that require frequent design changes and rapid prototyping, as they are simple to modify.

How Aluminum Molds Reduce Lead Times

The machinability of aluminum accelerates the creation of molds. Aluminum can be cut by CNC machines more quickly than steel, which in turn shortens the overall manufacturing process. Cooling during molding is accelerated by improved heat conductivity. Faster delivery and shorter cycles are the outcomes of this. It allows you to meet deadlines without sacrificing accuracy or performance.

Performance In Low To Medium Production Runs

Small and medium-sized batches work best with aluminum molds. They are ideal for short-term projects or the introduction of new products because they can easily handle thousands of shots. Aluminum offers a reasonably priced solution with short wait times for moderate volume requirements. You maintain control over your production budget while receiving high-quality parts on time.

Aluminum Vs Steel Injection Molds: Key Differences

| Feature | Aluminum Injection Mold | Steel Injection Mold |

| Cost | Lower manufacturing cost; ideal for tight budgets | Higher manufacturing cost; larger upfront investment |

| Lead Time | Shorter lead time due to easy machining | Longer lead time because machining is complex |

| Durability | Suitable for low to medium production runs | Best for high-volume, millions of cycles |

| Heat Dissipation | Excellent; faster cooling, shorter cycle times | Lower, longer cooling times |

| Flexibility | Easy to modify and update | Harder and more expensive to modify |

| Applications | Prototypes, small to medium runs | Large-scale production with consistent demand |

Benefits Of An Aluminum Injection Mold

Below are the key benefits you should know before deciding on aluminum for your next mold:

- Faster Cooling Times For Better Cycle Efficiency

Because aluminum conducts heat quickly, the cooling time is shortened. Shorter cycles increase part output and boost efficiency. Because of this, these molds are ideal for production processes where time-to-market and speed are critical.

- Lower Tooling Costs

Compared to steel, these molds are less expensive to make. Costs are decreased by easier machining, as it requires less labor and reduces tool wear. Aluminum is therefore a cost-effective choice for quick product development projects and small runs.

- Great For Design Changes And Rapid Prototyping

Quick design changes are easily accommodated with this mold option. They are perfect for rapid prototyping because of their flexibility, which enables you to test and improve designs rapidly without experiencing significant delays or costly retooling expenses during development.

- Surface Finish And Machining Advantages

Aluminum machines easily, producing smooth surfaces and precise details. Molds are ready sooner, thanks to shorter lead times resulting from faster machining. This speed and finish combination enables the production of high-quality parts quickly and affordably.

How To Make Aluminum Injection Molds

For machinability and durability, start with robust aluminum types such as 7075 or 6061. Creating precise mold cavities and ensuring uniform quality throughout the manufacturing process depend on CNC machining.

Key Steps: Milling, EDM, And Polishing

Milling shapes the mold precisely, while EDM handles fine details. Post machining, polishing ensures a smooth surface for improved plastic flow. Good finishing saves post-production labor and raises part quality.

Tolerance And Precision Requirements

Tight tolerances are needed for injection molds if the pieces are to be uniform. High precision is necessary in the machining of aluminum molds to prevent flaws. Precise measurements ensure dependable performance during production runs as well as proper dimensions.

Common Applications For Aluminum Injection Molds

Here are the sectors where aluminum molds deliver the most value:

- Automotive Industry: With this tooling, you can speed up prototype creation and verification. Important for new automobile models and parts in a demanding automotive industry, they cut development time.

- Medical devices: Quick iterations are required in medical projects for testing and compliance. For this industry, aluminum molds are ideal since they enable quick prototyping and regular design modifications without incurring significant expenses.

- Electronics: Electronics need fast mold turnaround in response to regular product upgrades. The speed and flexibility provided by aluminum molds enable electronics businesses to release products more rapidly and easily accommodate design modifications.

- Consumer Products: Rapidly changing trends require rapid tooling. Aluminum molds offer affordable and fast solutions for small to medium production runs, thereby shortening the time-to-market for new products.

Conclusion:

Speed, flexibility, and lower pricing are available with aluminum injection molds. Compared to conventional steel molds, they help shorten lead times and speed up and improve your production process. Good design and precise production are crucial for mold performance.

Working with qualified experts ensures that your molds meet quality criteria and produce consistent results throughout the entire manufacturing life cycle. Fengchi provides expert molding solutions that are both quick and precise. For reliable aluminum injection molds tailored to your needs and to help you achieve cost-effective, high-quality manufacturing, contact us today.